Titanium dioxide as well as preparation method thereof, slurry material of solar battery as well as preparation method thereof and solar battery

A technology for solar cells and titanium dioxide, applied in the field of solar cells, can solve the problems of uneven size distribution, difficult to control the size of sub-micron titanium dioxide, etc., and achieve the effects of uniform size distribution, improved photoelectric conversion efficiency, and good adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing submicron titanium dioxide, which includes the following steps:

[0036] Step 1: Prepare ammonia water (28% by mass) and distilled water into an ammonia solution, where the ratio of ammonia to water (including water in ammonia) is 1:20, and press 1 The titanium sulfate is heated and hydrolyzed in the ammonia solution for 8 hours at a mass ratio of 10 to form a colloidal solution.

[0037] Step 2: React the colloidal solution prepared in Step 1 in a water bath at 130°C for 48 hours to obtain a submicron titanium dioxide suspension.

[0038] Step 3: Centrifuge the above sub-micron titanium dioxide suspension at a speed of 4000 r / min for 30 min, wash with water, collect the precipitate, and dry at 70° C. to obtain sub-micron titanium dioxide powder.

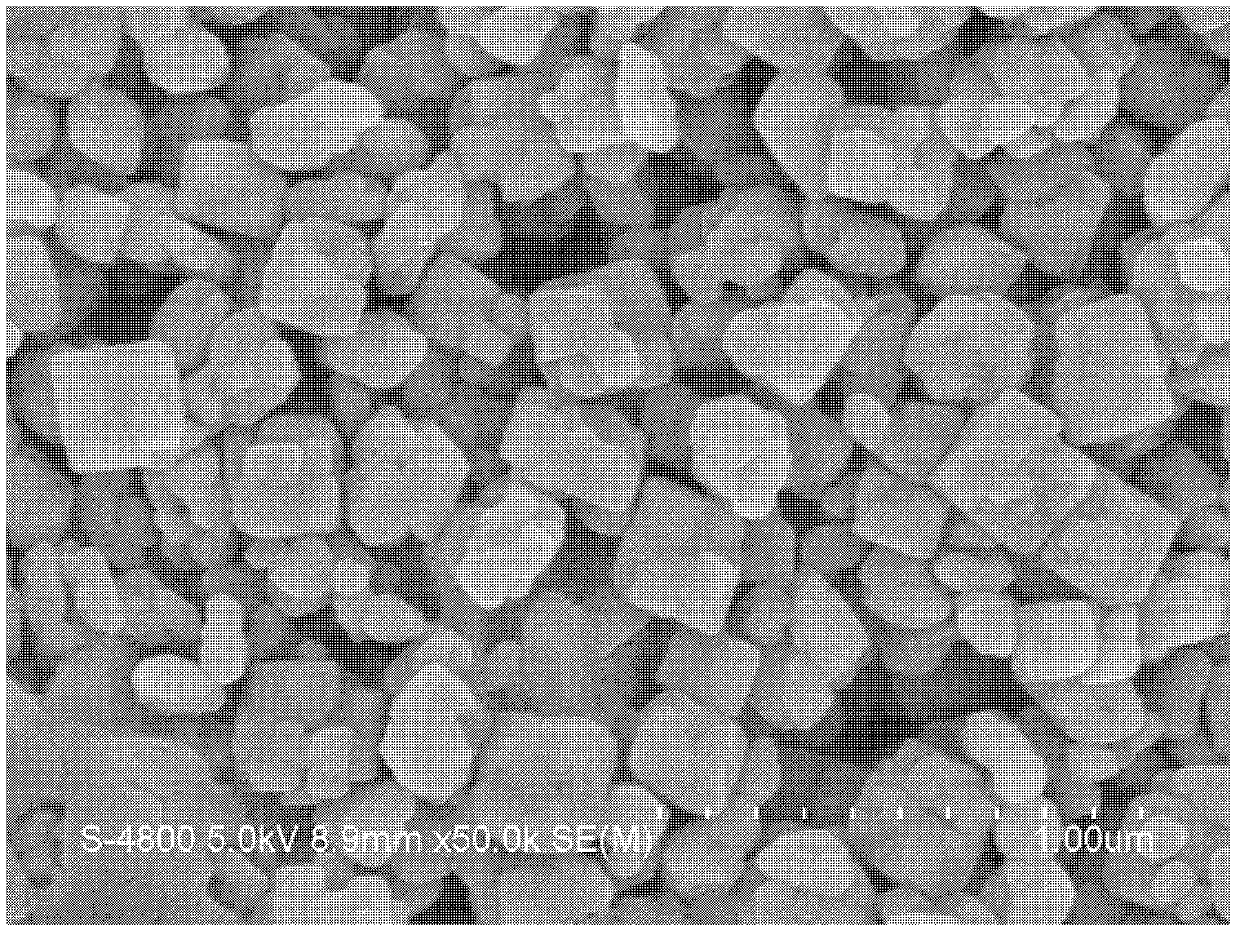

[0039] The sub-micron titanium dioxide powder prepared in this example was scanned by S-4800 scanning electron microscope under 50,000 times magnification. The results are shown in figu...

Embodiment 2

[0048] This embodiment provides a method for preparing submicron titanium dioxide, which includes the following steps:

[0049] Step 1: Prepare an aqueous solution of sodium hydroxide and distilled water at a ratio of 1:1, and heat and hydrolyze tetrabutyl titanate in the aqueous solution at a mass ratio of 1:5 in a water bath at 30°C for 1 hour , Forming a colloidal solution.

[0050] Step 2: The colloidal solution prepared in Step 1 is reacted in a hydrothermal kettle for 40 hours under a water bath at 100° C. to obtain a submicron titanium dioxide suspension.

[0051] Step 3: Centrifuge the above sub-micron titanium dioxide suspension at a speed of 4000 r / min for 30 min, wash with water, collect the precipitate, and dry at 70° C. to obtain sub-micron titanium dioxide powder.

[0052] Optionally, the prepared submicron titanium dioxide powder can be used to prepare the dye-sensitized solar cell scattering layer slurry, and the preparation method includes the following steps:

[0053]...

Embodiment 3

[0060] This embodiment provides a method for preparing submicron titanium dioxide, which includes the following steps:

[0061] Step 1: Prepare a mixture of potassium hydroxide and sodium hydroxide and distilled water into an aqueous solution, wherein the mixture and distilled water are in a ratio of 1:100, and the potassium hydroxide and sodium hydroxide in the mixture are in a ratio The ratio is 1:1; in a water bath at 70°C, isopropyl titanate is heated and hydrolyzed in the aqueous solution at a mass ratio of 1:20 for 10 hours to form a colloidal solution.

[0062] Step 2: React the colloidal solution prepared in Step 1 in a water bath at 160°C for 3 hours in a hydrothermal kettle to obtain a submicron titanium dioxide suspension.

[0063] Step 3: Centrifuge the above sub-micron titanium dioxide suspension at a speed of 4000 r / min for 30 min, wash with water, collect the precipitate, and dry at 70° C. to obtain sub-micron titanium dioxide powder.

[0064] Optionally, the prepared s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com