Preparation method of graphene/sulfur composite material, and application of graphene/sulfur composite material in lithium-sulfur battery

A composite material and graphene technology, applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems affecting the charge-discharge cycle performance of lithium-sulfur batteries, improve the charge-discharge cycle performance, enhance electrode conductivity, Good capacity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

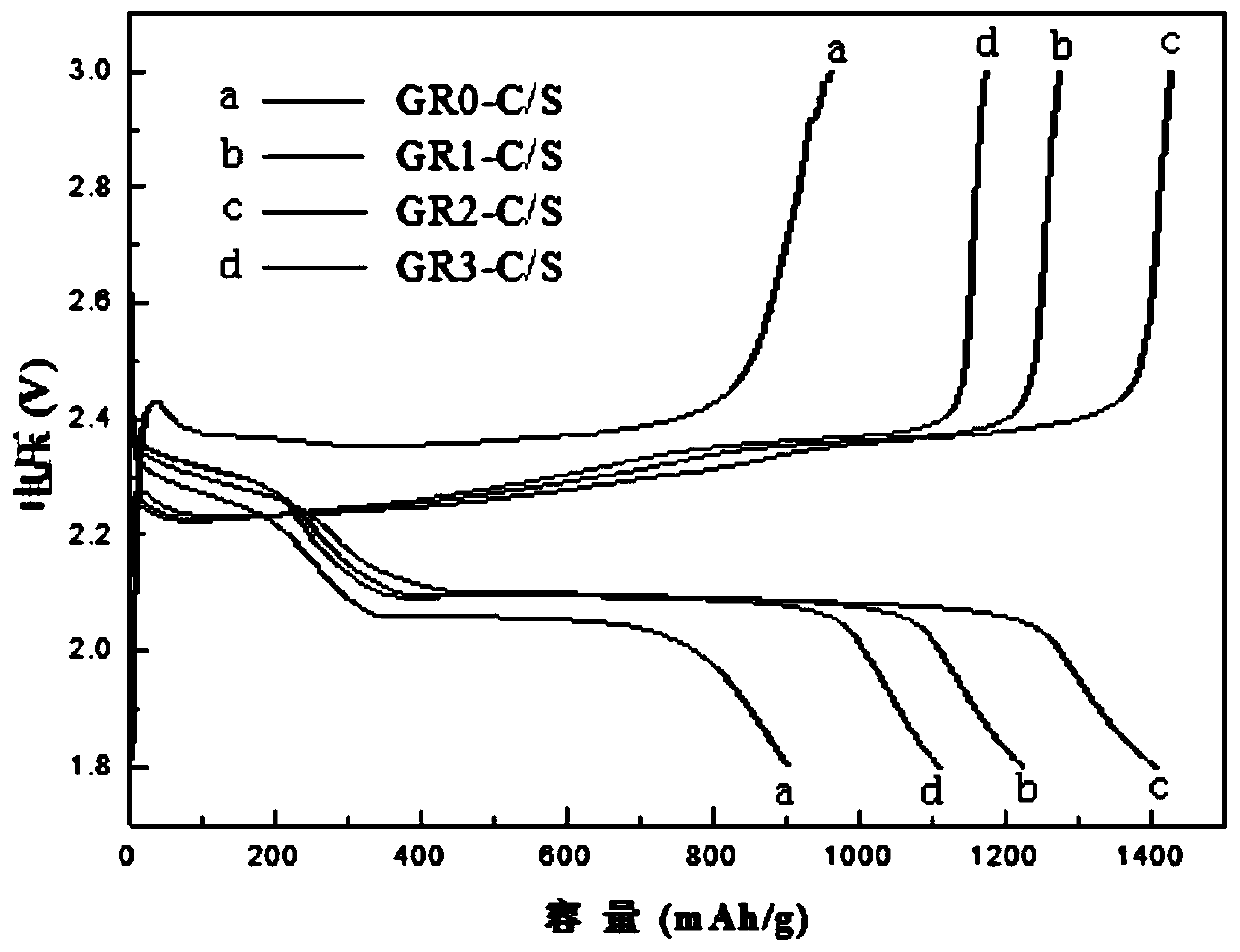

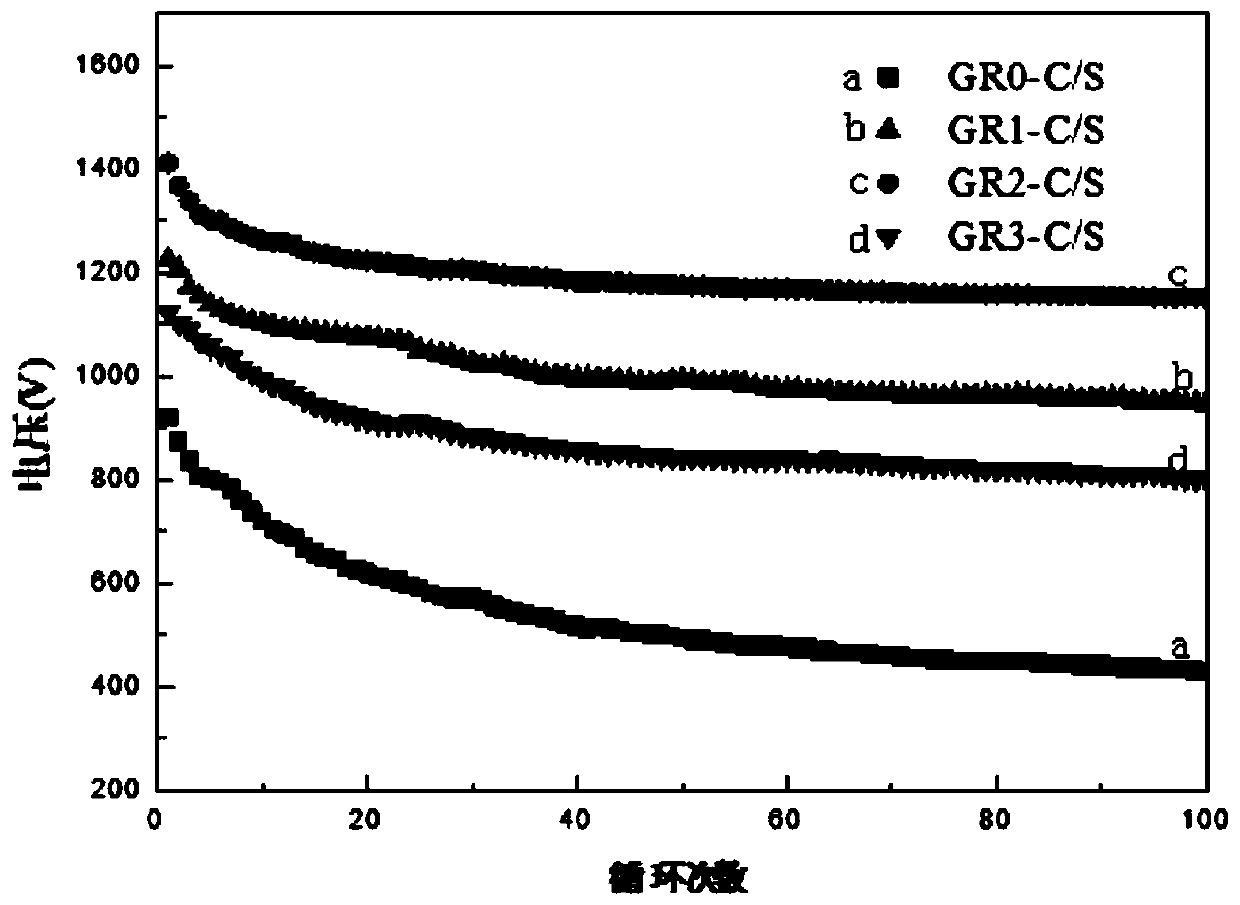

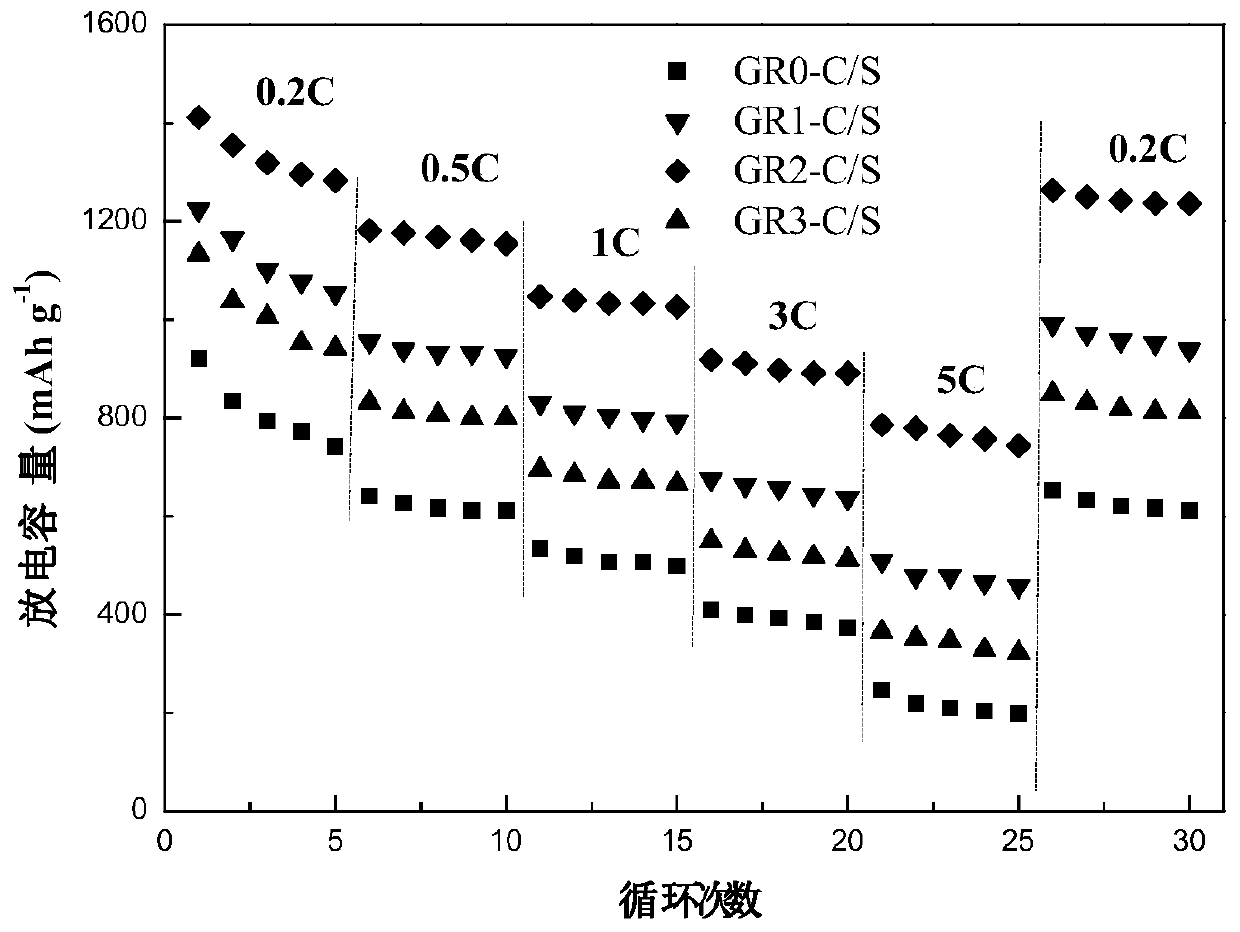

[0030] A preparation method of graphene / sulfur composite material, comprising the following steps:

[0031] (1) Mix formaldehyde and resorcinol according to the molar ratio of 2:1, then add graphene, the molar ratio of graphene and resorcinol is 1:2, and then under the constant temperature environment of 85°C, in the oil bath condition Down, stirring speed 160r / min, react 10h, obtain organogel;

[0032] (2) drying the organogel prepared above in an oven at 100° C. under normal pressure for 24 hours to obtain the organogel;

[0033] (3) Next, the organogel in the above step (2) was heated in a nitrogen atmosphere at 5°C min -1 The heating rate was increased to 850° C., and the carbonization was carried out at a high temperature for 8 hours to obtain a graphene-modified carbon material.

[0034] (4) The graphene-modified carbon material and sublimed sulfur were impregnated at 150° C. for 20 h at a mass ratio of 3:4 to obtain a graphene / sulfur composite material.

Embodiment 2

[0036] A preparation method of graphene / sulfur composite material, comprising the following steps:

[0037] (1) Mix formaldehyde and resorcinol according to the molar ratio of 2:1, then add graphene, the molar ratio of graphene and resorcinol is 1:1, and then under the constant temperature environment of 85 ℃, in the oil bath condition Down, stirring speed 160r / min, react 10h, obtain organogel;

[0038] (2) drying the organogel prepared above in an oven at 100° C. under normal pressure for 24 hours to obtain the organogel;

[0039] (3) Next, the organogel in the above step (2) was heated in a nitrogen atmosphere at 5°C min -1 The heating rate was increased to 850° C., and the carbonization was carried out at a high temperature for 8 hours to obtain a graphene-modified carbon material.

[0040] (4) Immerse the graphene-modified carbon material and sublimed sulfur at a mass ratio of 3:4 at 150°C for 20 hours to obtain a graphene-sulfur composite material, and use the graphene-...

Embodiment 3

[0042] A preparation method of graphene / sulfur composite material, comprising the following steps:

[0043] (1) Mix formaldehyde and resorcinol according to the molar ratio of 2:1, then add graphene, the molar ratio of graphene and resorcinol is 1:1.5, and then in the constant temperature environment of 85°C, in the oil bath condition Down, stirring speed 160r / min, react 10h, obtain organogel;

[0044] (2) drying the organogel prepared above in an oven at 100° C. under normal pressure for 24 hours to obtain the organogel;

[0045] (3) Next, the organogel in the above step (2) was heated in a nitrogen atmosphere at 5°C min -1 The heating rate was increased to 850° C., and the carbonization was carried out at a high temperature for 8 hours to obtain a graphene-modified carbon material.

[0046] (4) Immerse the graphene-modified carbon material and sublimed sulfur at a mass ratio of 3:4 at 150°C for 20 hours to obtain a graphene-sulfur composite material, and use the graphene-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com