Integrated solar sludge drying system

A sludge drying and solar energy technology, which is applied in dewatering/drying/concentrating sludge treatment, energy and wastewater treatment, etc. The effect of reducing floor space and increasing residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

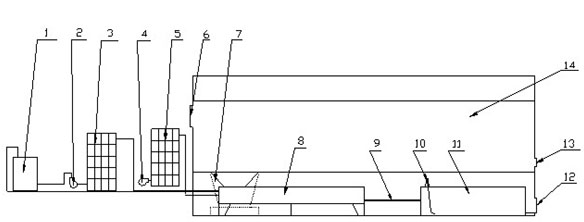

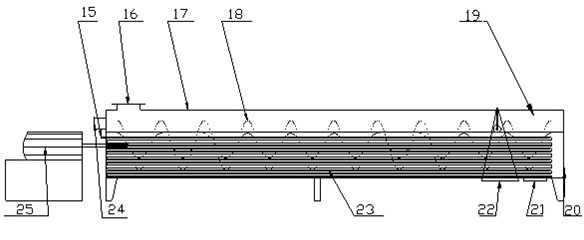

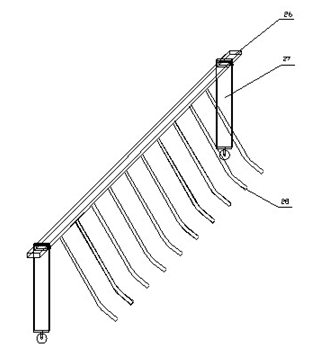

[0021] The whole integrated solar sludge drying system mainly includes: multi-functional solar room 14, thermal oil tank 1, solar collector 3, fan 4, solar air collector 5, sludge feeder 7, shaftless screw dryer 8 and mud pool 11.

[0022] see figure 1 , the solar heat collector 3 and the solar air heat collector 5 are arranged in a position with sufficient light sources to collect solar energy, the heat generated by the solar energy heats the air and heat transfer oil respectively, and the hot air and hot oil are transported by the oil pump 2 and the fan 4 Heat it to the shaftless screw dryer 8 arranged in a triangular three-dimensional arrangement; after preheating for a certain period of time, the sludge feeder 7 runs to pour the mechanically dehydrated sludge into the shaftless screw dryer 8, and adjust the hot air The air volume and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com