Method for preparing cyclopentanone through cyclopentanol dehydrogenation

A technology for cyclopentanol and cyclopentanone, which is applied in the field of cyclopentanol dehydrogenation to prepare cyclopentanone, can solve the problems of low catalyst efficiency and high energy consumption, and achieve the effects of high use efficiency, low energy consumption and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

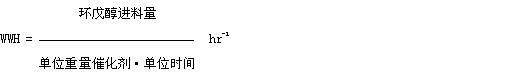

Method used

Image

Examples

Embodiment 1~10

[0022] The dehydrogenation reaction is carried out in a reactive distillation unit, which consists of a dehydrogenation reactor and a rectification column. The dehydrogenation reactor is a 5000ml glass reactor with a discharge port at the bottom. The material containing the catalyst enters a slurry pump from the discharge port, and the material is pumped to a heat exchanger and heated to the required temperature. The upper part of the reactor returns to the reactor through a liquid distributor, so that the catalyst is evenly distributed in the liquid. The top of the reactor is connected with a rectification column. The theoretical plate number of the rectification column is 45. A condensing reflux device with a vent and a discharge port is installed on the top of the rectification column. The system pressure is controlled by a vacuum pump.

[0023] First add 3000 grams of cyclopentanol to the reactor, and then add 300 grams of modified amorphous Raney nickel catalyst composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com