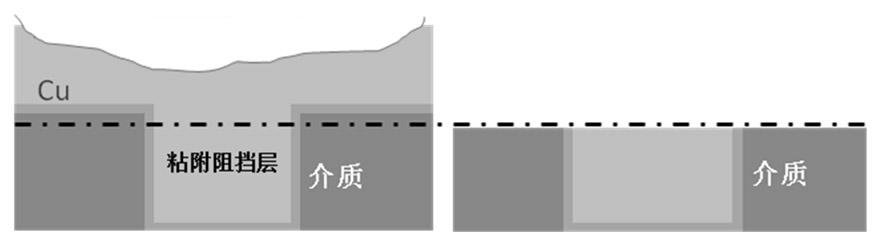

Polishing solution used in polishing process with metal ruthenium as adhesive barrier layer in copper interconnection

A metal ruthenium and polishing liquid technology, applied in the field of microelectronics technology, can solve problems such as Cu desorption, achieve the effects of reducing defects, preventing reliability problems, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

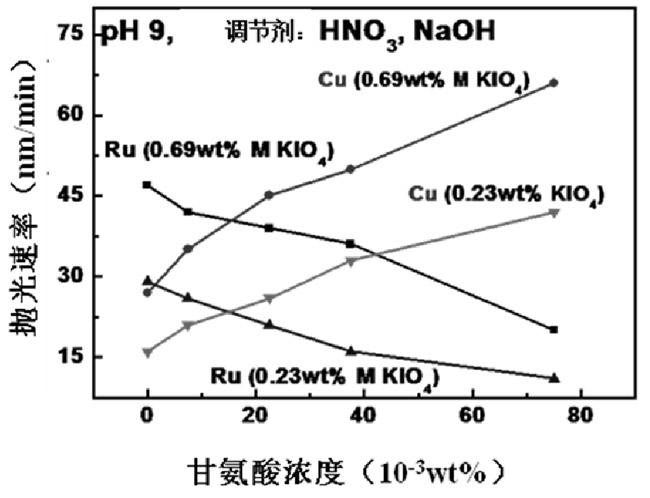

[0034] Polishing fluid preparation: 5% SiO by weight 2 Hydrosol, abrasive particle size is 50nm; Accounting for total weight is 0.05% alkylphenol polyoxyethylene ether; Accounting for total weight is 0.23% potassium periodate; Glycine of different weight concentrations and the water of surplus; Nitric acid and potassium hydroxide were used to adjust the pH to 9.0.

[0035] Polishing equipment and mechanical parameter setting: The polishing machine used in this embodiment is the CP-4 desktop polishing machine produced by CETR Company; The rotational speed of the polishing table is 90 rpm.

Embodiment 2

[0044] Polishing fluid preparation: 5% SiO by weight 2 Hydrosol, the abrasive particle size is 50nm; Accounting for the total weight is 0.05% alkylphenol polyoxyethylene ether; Accounting for the total weight is 0.0225% glycine; Different weight concentrations of potassium periodate and the water of the remainder; Nitric acid and potassium hydroxide were used to adjust the pH to 9.0.

[0045] The experimental equipment and parameters are the same as in Example 1.

[0046] Table 2: Polishing rates of Ru and Cu in polishing fluids containing different weight concentrations of potassium periodate

[0047] Potassium periodate (wt%) 0.23 0.69 1.15 Ru polishing rate (nm / min) 18 39 55 Cu polishing rate (nm / min) 27 45 62

[0048] It can be seen from the data in Table 2 that adding a small amount of glycine (less than 0.225wt%) can effectively suppress the polishing rate of Ru and increase the polishing rate of Cu, making the polishing rate of Cu grea...

Embodiment 3

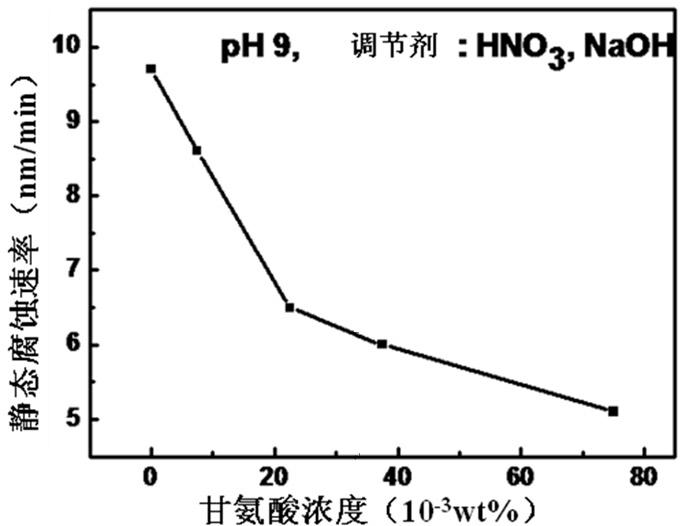

[0050] Polishing liquid preparation: accounting for 0.05% of the total weight of alkylphenol polyoxyethylene ether; accounting for 0.69% of the total weight of potassium periodate; different weight concentrations of glycine and the rest of the water; dilute nitric acid, potassium hydroxide Adjust the pH to 9.0.

[0051] Such as image 3 As shown, the static corrosion rate of Ru decreases gradually with the increase of glycine concentration. After adding 0.075wt% glycine, the static corrosion rate of Ru decreased to 6nm / min, indicating that glycine can well inhibit the corrosion of Ru.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com