Production process for elastic knitted fabric

A technology of knitted fabric and production process, which is applied in the direction of fabric elongation, fabric surface trimming, textiles and papermaking, etc. It can solve the problems of unfavorable market development and high price, and achieve excellent functions, wearing comfort, and uniform heat shrinkage , Improve the effect of dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

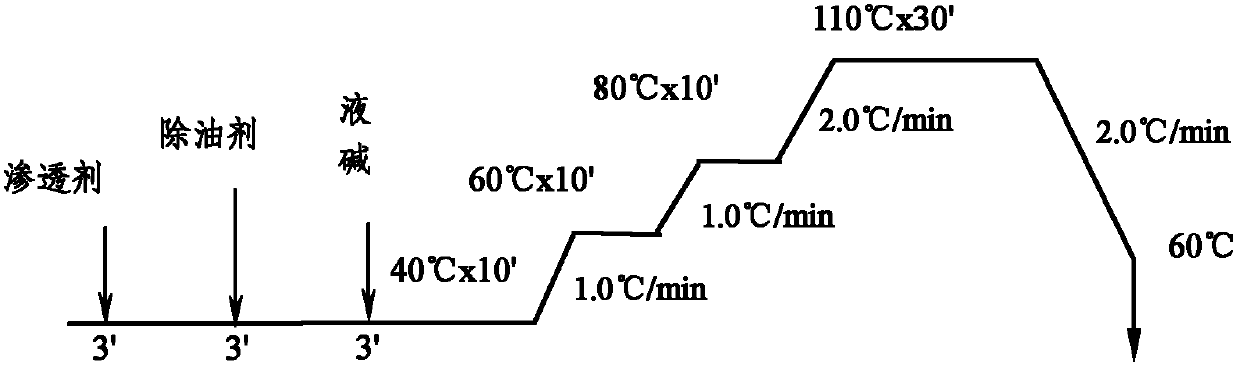

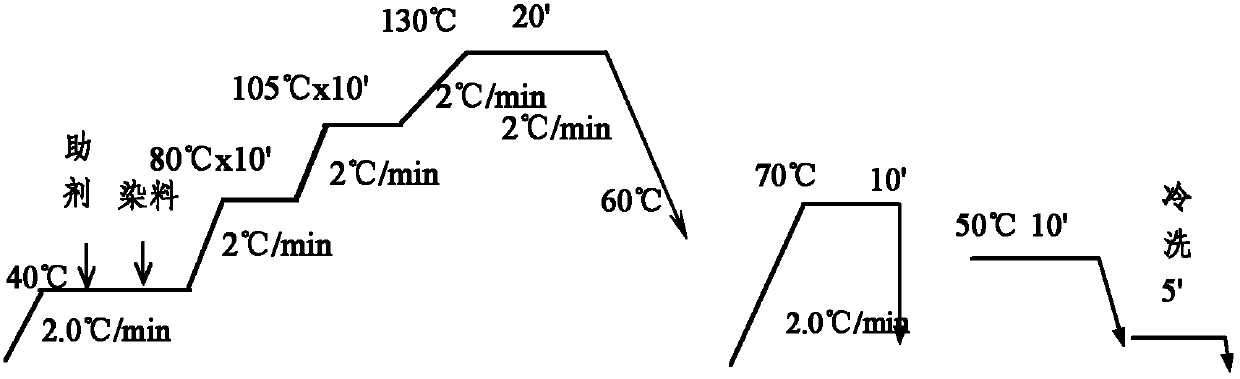

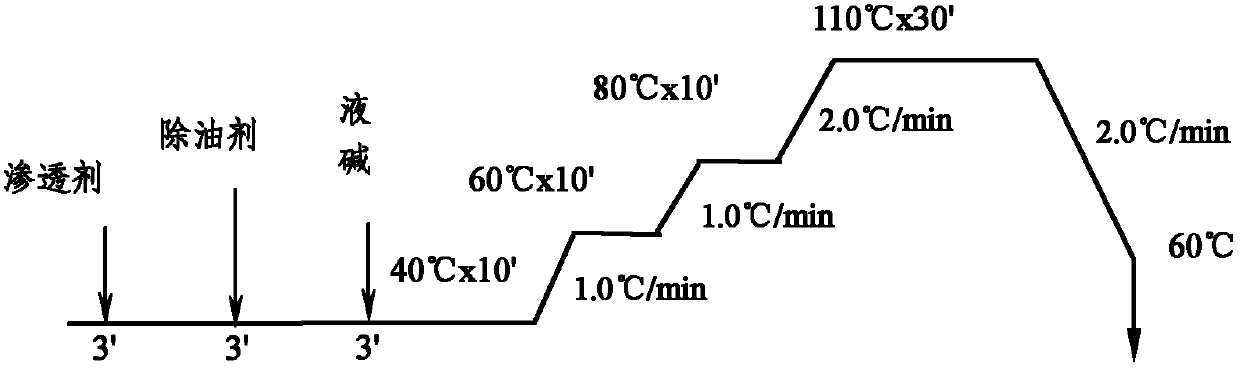

[0024] A production process of elastic knitted fabrics, including raw material preparation → fabric arrangement → pre-shrinking process → dyeing process → softening treatment → dehydration → wet opening → shaping process → finished product inspection → packaging.

[0025] Raw materials are prepared by using Italian 28-needle 30″90F single-jersey circular knitting machine to weave the gray cloth containing PET / PTT composite fiber. Specifically, PTT / PET composite fiber can be used with different fibers such as cotton, nylon, viscose, tencel, and modal. Proportional implementation of mixed weaving and interweaving, the technical parameters of gray cloth weaving are: gram weight 75g / m 2 , door width 110×2cm polyester thread length: 26.5cm / 100G, yarn feeding tension: 2-3g.

[0026] Pre-shrinking process, pre-shrinking the gray cloth, using different shrinkage temperature sections to make the PTT and PET fibers in the PET / PTT composite fiber shrink to different degrees, forming a pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com