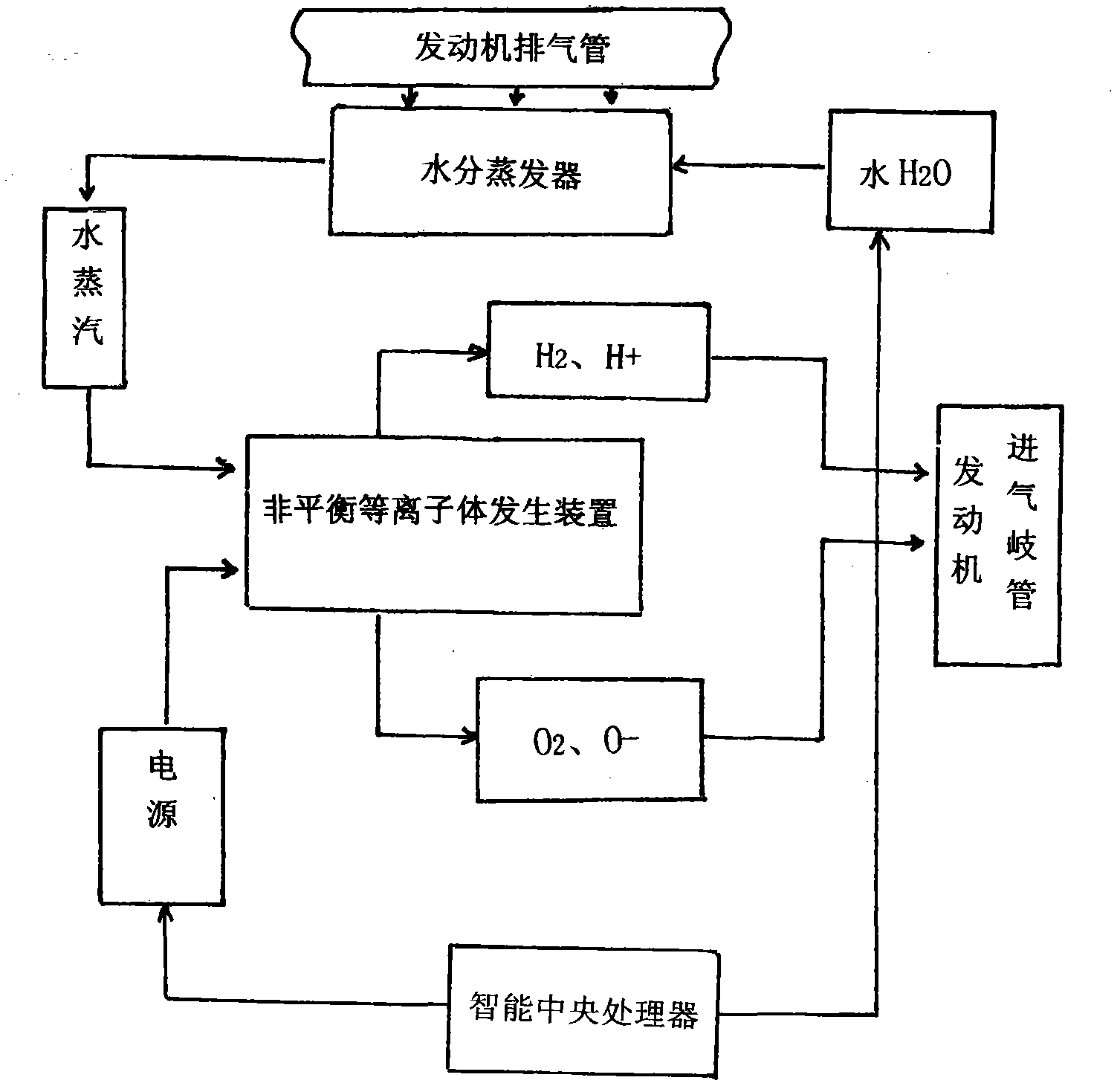

Automatic hydrogen and oxygen generation method for engine and energy-saving equipment

An oxygen production method and engine technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve problems such as difficulties in implementation and promotion, great difficulty, large design defects, etc., and achieve convenient implementation and promotion, increased output power, and reduced carbon monoxide Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

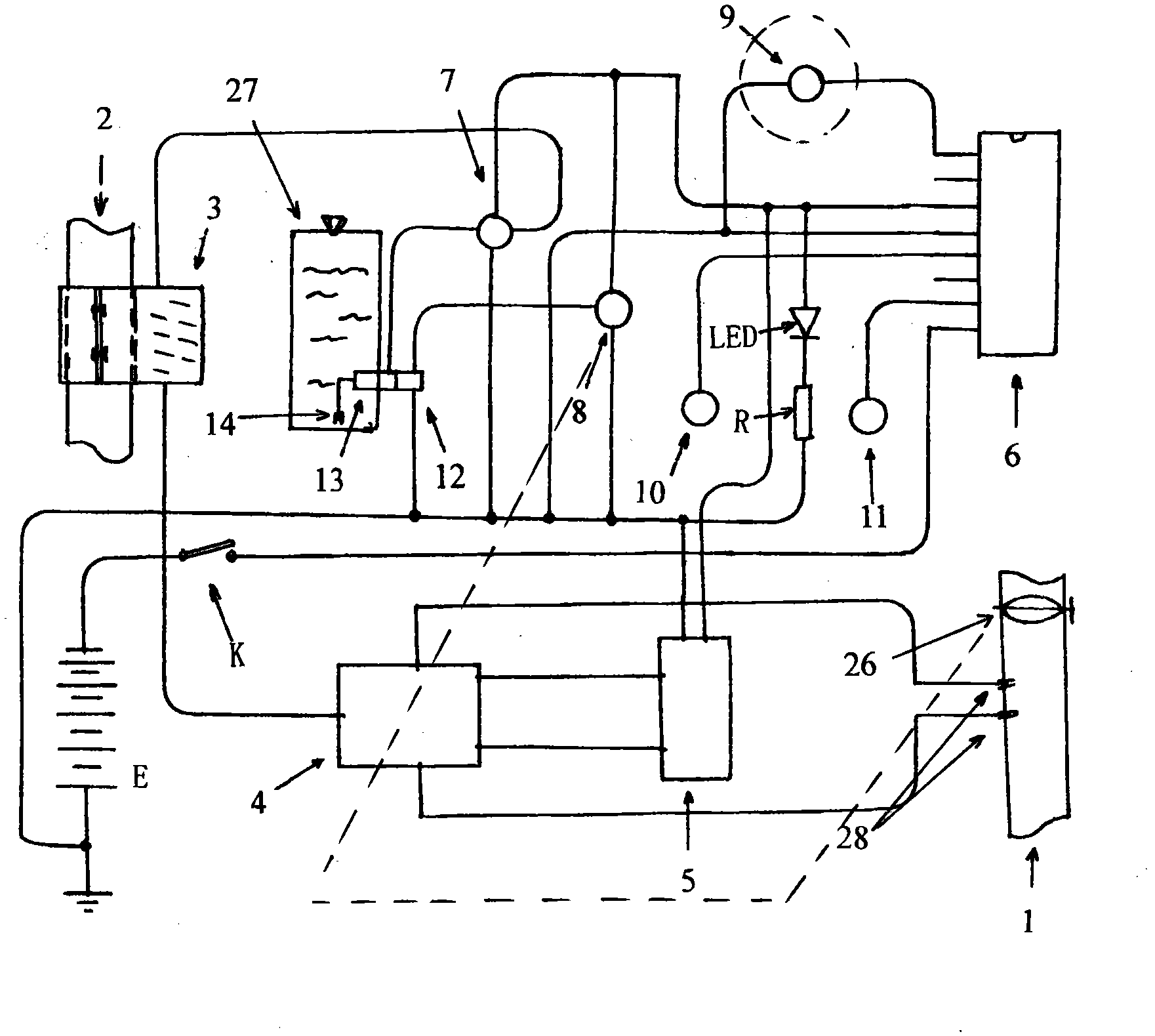

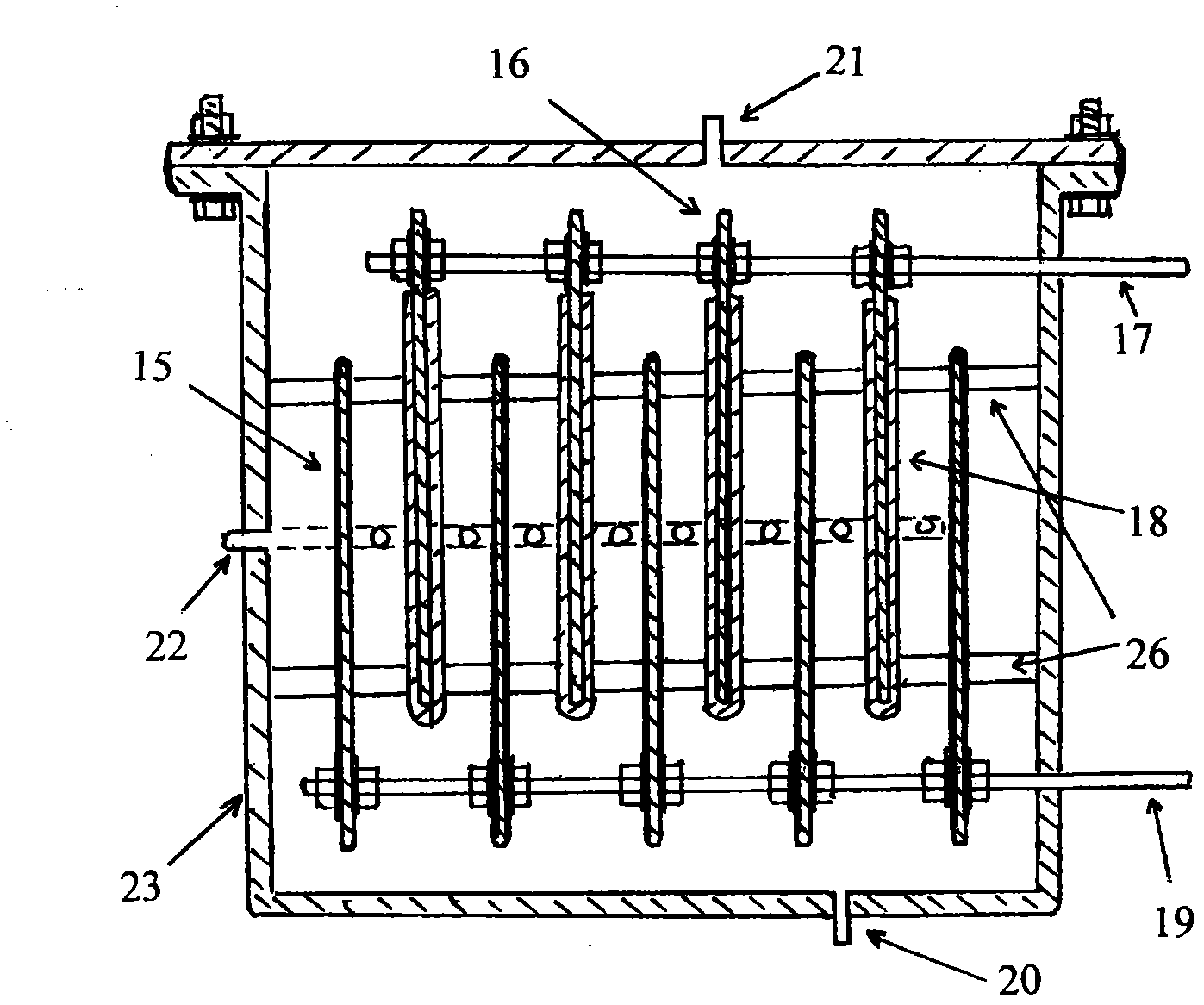

[0020] The technical characterictic of the present invention is; Moisture evaporator (3) and electrolytic cracker (4) are installed on engine exhaust pipe (2), and injection throat (19) is installed on engine intake manifold (1) , on the water evaporator (3), a thermoelectric sensor (5), a water inlet hole (14), and an air outlet hole (13) are installed, and a nickel metal catalytic plate (18) is also installed in the water evaporator (3). An anode plate (16) and an anode ceramic isolation net (15) are installed in the electrolytic cracker (4), and the anode plate (16) is fixed on the shell of the electrolytic cracker (4) with a fixed gong bolt (17). The shell of the electrolytic cracker (4) made of stainless steel is also the cathode during electrolytic cracking work, and an air inlet (12) and an air outlet (11) are also provided on the electrolytic cracker (4). Water pump (9) and water pump motor (8) are installed on the water tank (10), and one end of electromagnetic switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com