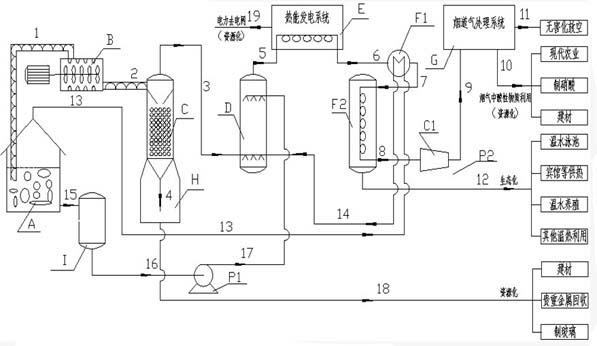

Process of municipal solid waste treatment and utilization system

A technology of municipal solid waste and garbage, applied in gas treatment, steam generation method using heat carrier, petroleum industry, etc., can solve the problems of polluting the surrounding atmospheric environment, difficulty in large-scale promotion, and threat to residents' health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Pile 60t of domestic garbage in the garbage storage subsystem A, the temperature is normal temperature, and the pressure is 0.095MPa. Wherein the volume of the landfill leachate collection container I is 3M 3 . The leachate is transported to the combustion subsystem D through the delivery pump P1, atomized by the nozzle, and then completely combusted. The garbage release gas emitted from the exhaust pipe 13 at the top of the stacking subsystem A is metered through the negative pressure pipe, and after heat exchange with a heat exchanger F1 of the waste heat recovery and utilization subsystem F, it is sent to the combustion subsystem D for complete combustion. combustion. The solid waste is sent to the crushing and screening subsystem B through the automatic lifting conveying device 1 at a flow rate of 3t / h for crushing and screening. A small amount of hard-to-crunch waste such as metal blocks, wires, and plastic films is removed in the screening equipment. The size o...

Embodiment 2

[0051] Garbage stacking system A stores 120t of domestic garbage, its temperature is normal temperature, and its pressure is 0.098MPa. Wherein the solution volume of landfill leachate collection container I is 6M 3 . The leachate is transported to the combustion subsystem D through the delivery pump P1, atomized by the nozzle, and then completely combusted. The garbage release gas emitted from the exhaust pipe 13 at the top of the stacking subsystem A is metered through the negative pressure pipe, and after heat exchange with a heat exchanger F1 of the waste heat recovery and utilization subsystem F, it is sent to the combustion subsystem D for complete combustion. combustion. The solid waste is sent to the crushing and screening subsystem B through the automatic lifting conveying device 1 at a flow rate of 4t / h for crushing and screening. A small amount of difficult-to-crunch waste such as metal blocks, wires, and plastic films is removed in the screening equipment. The si...

Embodiment 3

[0057] Garbage stacking system A stores 240 tons of domestic garbage, its temperature is normal temperature, and its pressure is 0.097MPa. Wherein the solvent of landfill leachate collection container I is 5M 3 . The leachate is transported to the combustion subsystem D through the delivery pump P1, atomized by the nozzle, and then completely combusted. The garbage release gas emitted from the exhaust pipe 13 at the top of the stacking subsystem A is metered through the negative pressure pipe, and after heat exchange with a heat exchanger F1 of the waste heat recovery and utilization subsystem F, it is sent to the combustion subsystem D for complete combustion. combustion. The solid waste is sent to the crushing and screening subsystem B through the automatic lifting conveying device 1 at a flow rate of 5t / h for crushing and screening. A small amount of hard-to-crunch waste such as metal blocks, wires, and plastic films is removed in the screening equipment. The size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com