Plant growth regulating composition and its application

A plant growth regulator and plant growth regulator technology, applied in the direction of plant growth regulators, plant growth regulators, applications, etc., to achieve the effects of expanding control targets, reducing use costs, and promoting fruit growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of emulsifiable concentrate: (A is S-ABA in the following examples, and B is gibberellic acid (GA 3 , or GA 4+7 ))

[0041] (1) Product formula

[0042]

[0043] (2) Process flow

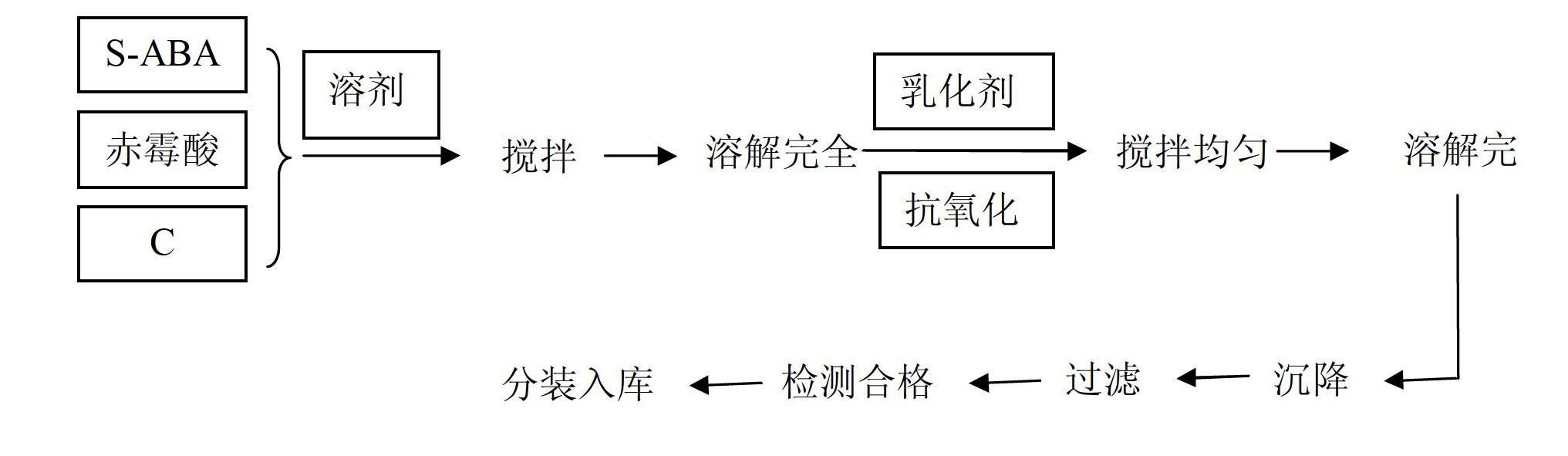

[0044] The above three formulations are respectively as follows figure 1 The shown technological process prepares emulsifiable concentrate:

[0045] Dissolve the active ingredient in the solvent N, N dimethyl octadecyl carboxamide and fatty acid methyl ester, stir, dissolve completely, then add additives Nongru 500#, Nongru 602#, antioxidant BHT, mix, emulsify and stir, settle, After filtering to remove impurities, the test is qualified and put into storage.

[0046] (3) Indicators of product control items (refer to HG / T 2467.2-2003, Standard Compilation Specification for Pesticide EC Products)

[0047]

[0048]

[0049] Note: Thermal storage stability test, under normal circumstances, should be tested at least once every six months.

Embodiment 2

[0051] Wettable powder preparation:

[0052] (1) Product formula

[0053]

[0054] (2) Process flow

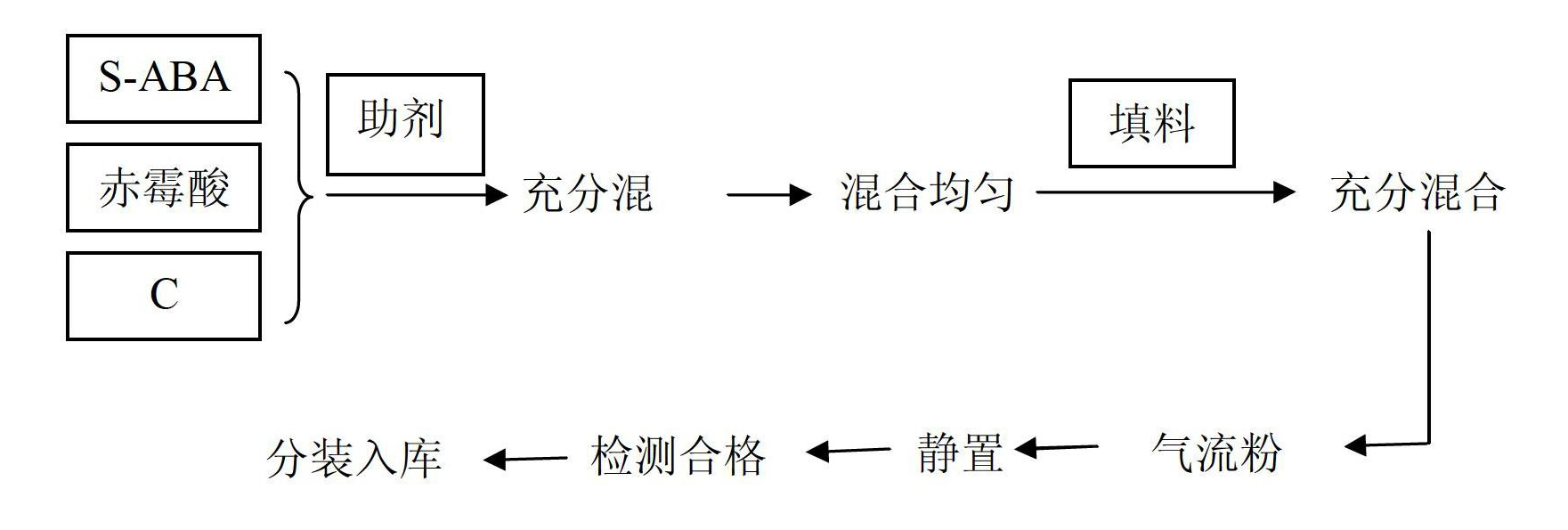

[0055] The above three formulations are respectively as follows figure 2 The process flow shown prepares wettable powder:

[0056] The active ingredients are fully mixed with the additives sodium lignosulfonate, NNO, and CMC, then the filler kaolin is added, mixed fully, jet crushed, left to stand, tested to be qualified, and put into storage.

[0057] (3) Indicators of product control items (refer to HG / T2467.3-2003 specification for preparation of pesticide wettable powder product standards)

[0058]

[0059]

[0060] Note: Thermal storage stability test, under normal circumstances, should be tested at least once every six months.

Embodiment 3

[0062] Soluble powder preparation:

[0063] (1) Product formula

[0064]

[0065] (2) Process flow

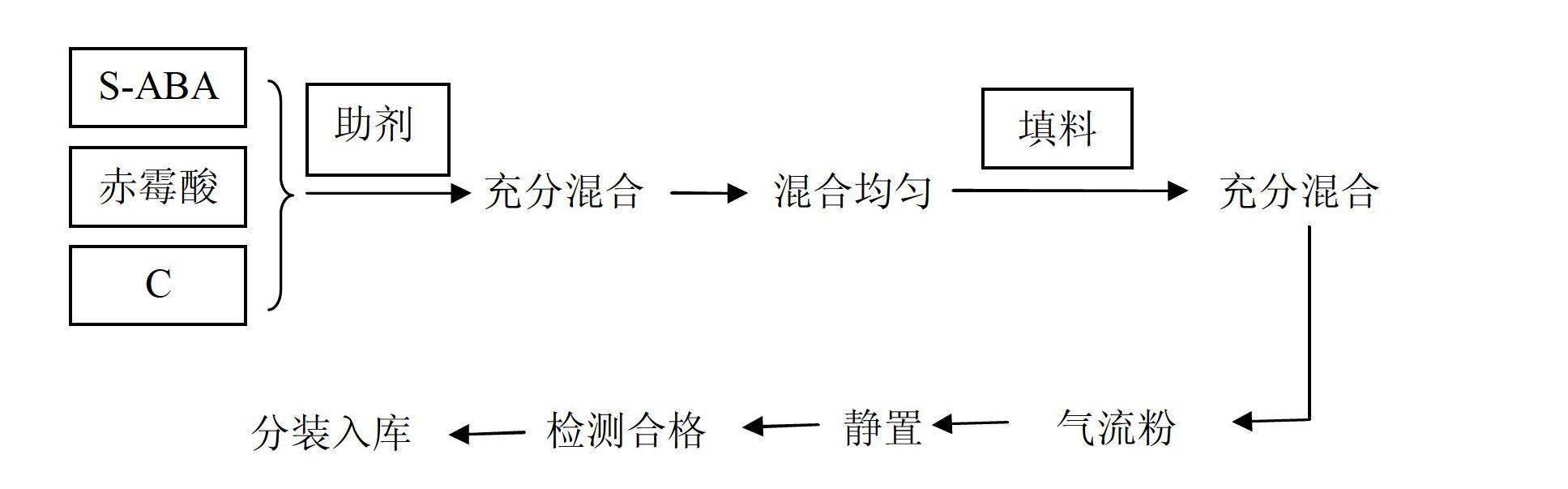

[0066] The above three formulations are respectively as follows image 3 The process flow shown prepares soluble powder:

[0067] Fully mix the active ingredients with additives sodium lignosulfonate, NNO and CMC, add filler soluble starch after mixing evenly, then fully mix, jet crush, stand still, pass the test, and put it into the warehouse.

[0068] (3) Indicators of product control items (refer to HG / T2467.15-2003, Specification for Compilation of Pesticide Soluble Powder Product Standards)

[0069]

[0070]

[0071] Note: Thermal storage stability test, under normal circumstances, should be tested at least once every six months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com