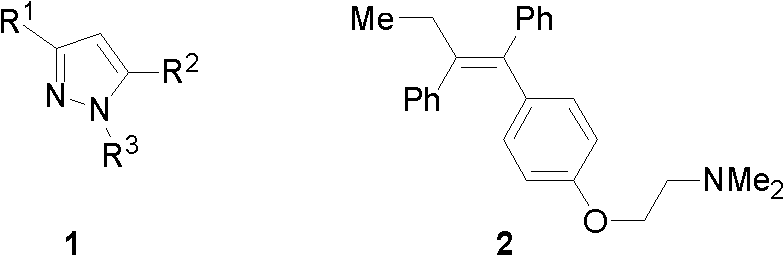

Preparation method of tetra-substituted olefin and its pyrazole derivative

A technology for pyrazole derivatives and substituents, which is applied in the field of preparation of tetrasubstituted olefins and pyrazole derivatives, can solve the problems of harsh reaction conditions, poor stereoselectivity, and cumbersome preparation routes, and achieve simple steps, easy operation, The effect of cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

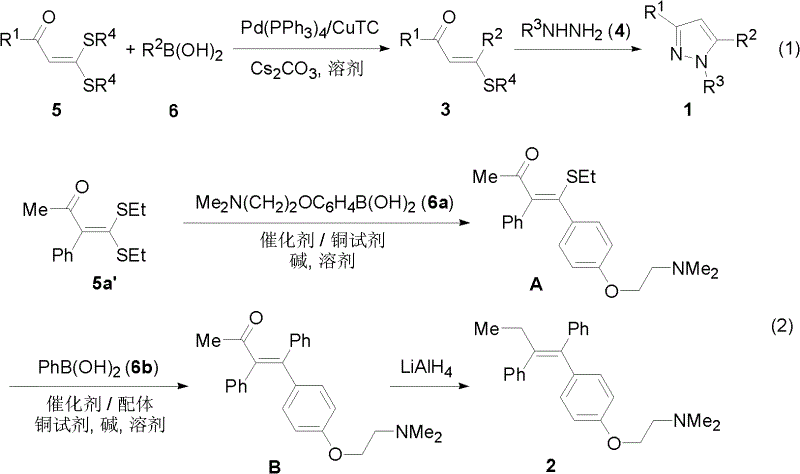

Method used

Image

Examples

Embodiment 1

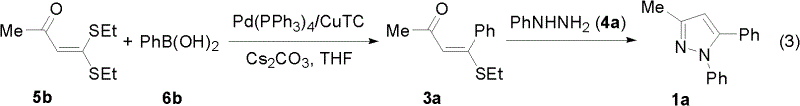

[0029]

[0030] Under nitrogen atmosphere, α-carbonyl dithioketene 5b (95mg, 0.50mmol), arylboronic acid 6b (91mg, 0.75mmol), Pd(PPh 3 ) 4 (43mg, 0.0375mmol), CuTC (191mg, 1.0mmol), Cs 2 CO 3 (326mg, 1.0mmol) and 5mL solvent THF were stirred at 50°C for 2h. After the reaction was finished, the mixture was cooled to room temperature, the reaction solution was filtered with diatomaceous earth, the filter cake was washed with 10 mL of dichloromethane, the filtrate was decompressed to remove volatile components, and then separated by silica gel column chromatography (eluent was petroleum ether ( 60-90° C.) / ethyl acetate, v / v=30:1), the yellow liquid intermediate 3a (100 mg, yield 97%) was obtained. Intermediate products were confirmed by NMR and high-resolution mass spectrometry.

[0031] Under nitrogen atmosphere, 3a (103mg, 0.50mmol), phenylhydrazine 4a (65mg, 0.60mmol), potassium tert-butoxide (112mg, 1.0mmol) and 5mL solvent tert-butanol were added successively to a 25m...

Embodiment 2

[0033] The reaction steps and operations are the same as those in Example 1, except that the reaction temperature in the second step is room temperature 25° C., and the reaction time is 24 hours. The reaction was stopped, and the target product 1a (10 mg, yield 9%) was obtained through the same post-treatment as above. It shows that the reaction temperature decreases and the reaction becomes slower.

Embodiment 3

[0035] The reaction steps and operations are the same as in Example 1, except that the second step reaction solvent is toluene. The reaction was stopped, and the target product 1a (30 mg, yield 26%) was obtained after post-processing. It shows that the use of aprotic solvent is not conducive to the condensation and cyclization reaction of 3 and hydrazine 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com