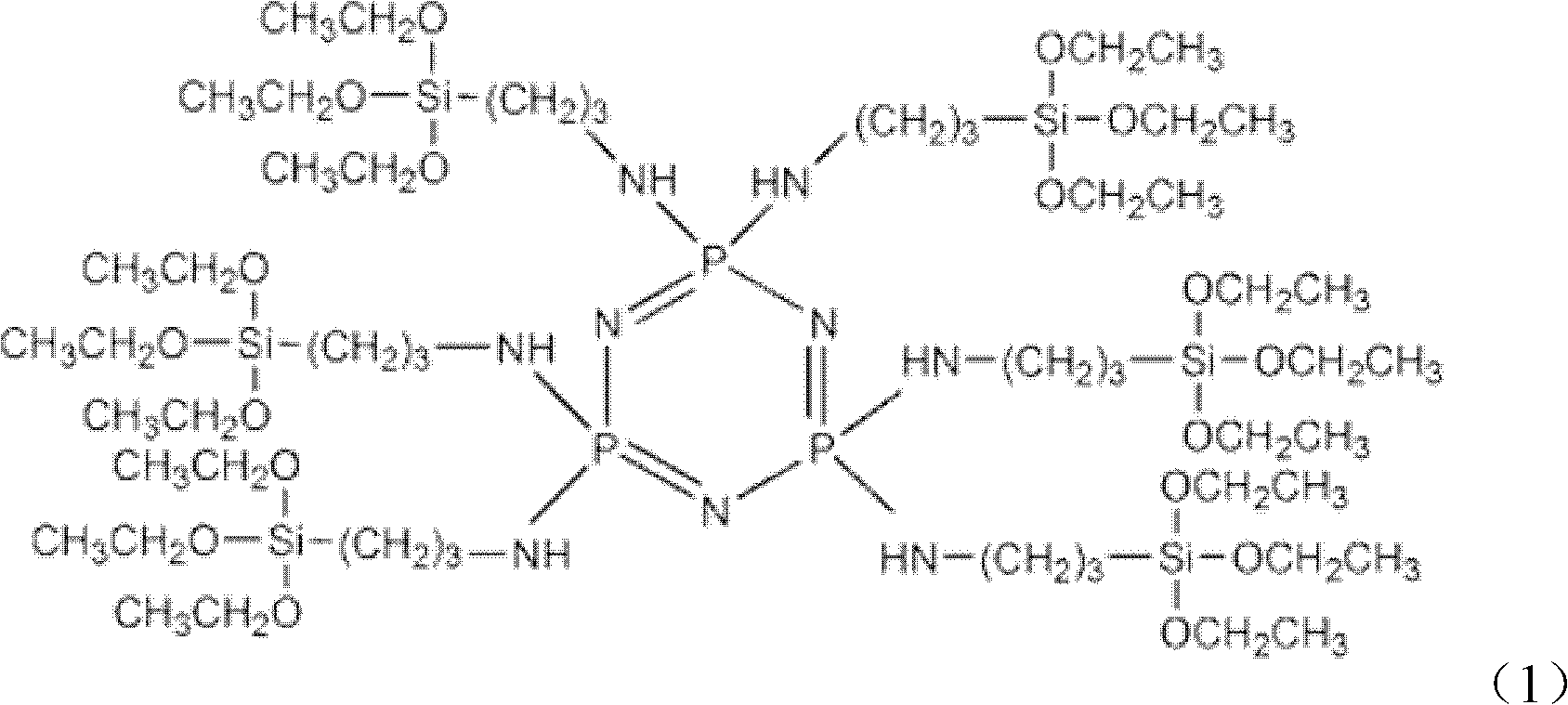

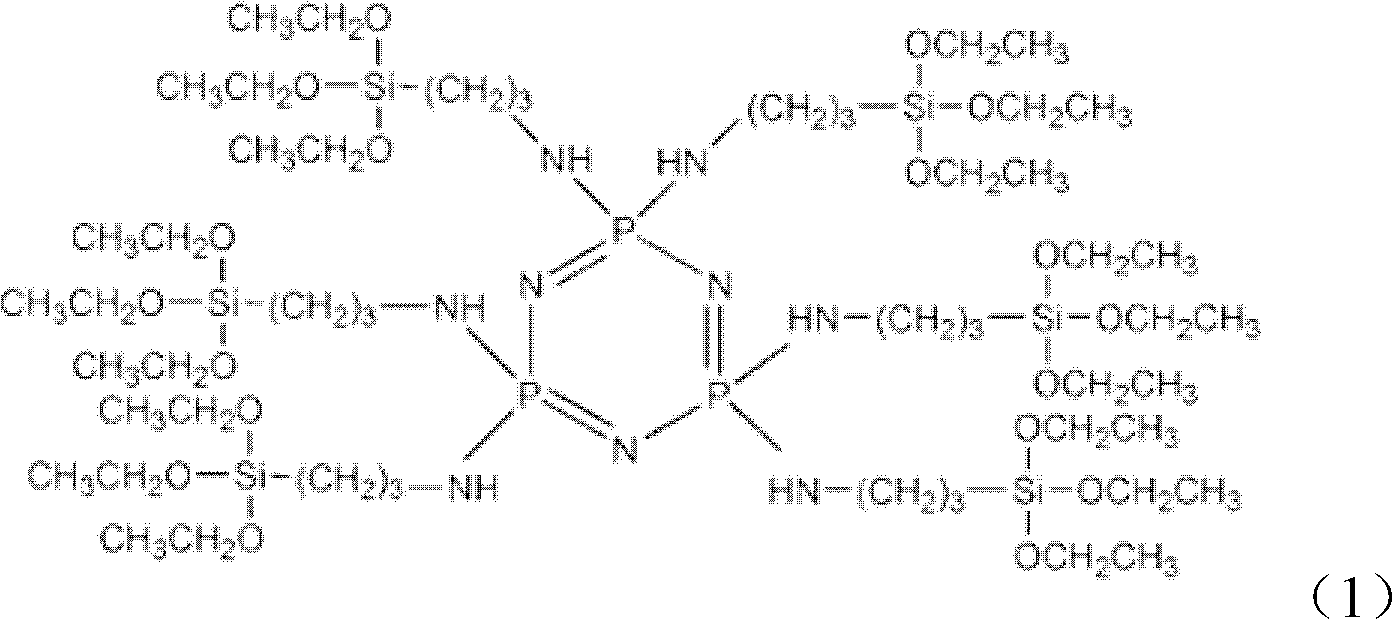

Method for preparing silicon-containing phosphonitrile modified ammonium polyphosphate flame retardant and application in flame-retardant polyolefin

A technology of ammonium polyphosphate and silicon-containing phosphazene, which is applied in the field of flame-retardant materials, can solve problems such as poor effect, poor compatibility, and penetration, and achieve the effects of improved heat release rate, mild preparation conditions, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Bake the ammonium polyphosphate APP-JLS in a vacuum oven at 80°C for 6 hours; dissolve APESP in absolute ethanol and mix thoroughly in a three-necked flask, the mass ratio of APESP to absolute ethanol is 1:5; then bake Add dry ammonium polyphosphate to the absolute ethanol solution of APESP, the mass ratio of APESP to APP is 1:7, stir and heat up to 50°C, after 40 minutes, remove the absolute ethanol, and then in a vacuum oven at 80°C Baked for 8 hours, and finally crushed into powder to obtain APESP modified ammonium polyphosphate flame retardant.

[0025] The modified ammonium polyphosphate flame retardant prepared by the above steps and polypropylene S1003 were compounded according to the ratio of 30:70 in mass ratio, and 0.1% of 1010 antioxidant and 0.2% of 168 antioxidant were added in mass ratio, squeezed The outlet temperature conditions were 170°C, 175°C, 180°C, 185°C, 180°C, 175°C, and the injection molding temperature conditions were 195°C, 195°C, 190°C, 185°C...

Embodiment 2

[0029] Bake the ammonium polyphosphate APP-JLS in an electric blast oven at 100°C for 4 hours; dissolve APESP in anhydrous methanol and mix thoroughly in a three-necked flask, the mass ratio of APESP to anhydrous methanol is 1:10; then Add the dried ammonium polyphosphate to the anhydrous methanol solution of APESP, the mass ratio of APESP to APP is 1:4, stir and heat up to 50°C, after 30 minutes, remove the anhydrous methanol, and then place in a vacuum oven for 80 Bake at ℃ for 12 hours, and finally pulverize into powder to obtain APESP modified ammonium polyphosphate flame retardant.

[0030] The modified ammonium polyphosphate flame retardant prepared by the above steps and polypropylene T30S were compounded according to the ratio of 30:70 in mass ratio, and 0.1% of 1010 antioxidant and 0.2% of 168 antioxidant were added in mass ratio, squeezed The outlet temperature conditions were 170°C, 175°C, 180°C, 185°C, 180°C, 175°C, and the injection molding temperature conditions ...

Embodiment 3

[0034] Dry the ammonium polyphosphate APP2100 in a vacuum oven at 80°C for 6 hours; dissolve APESP in absolute ethanol and mix thoroughly in a three-necked flask, the mass ratio of APESP to absolute ethanol is 1:2; then dry the Add ammonium polyphosphate to the absolute ethanol solution of APESP, the mass ratio of APESP to APP is 1:3, stir and heat up to 40°C, after 40 minutes, remove the absolute ethanol, and then dry in a vacuum oven at 80°C After 6 hours, it was finally crushed into powder to obtain APESP modified ammonium polyphosphate flame retardant.

[0035] Compound the modified ammonium polyphosphate flame retardant prepared by the above steps, polypropylene S1003 according to the ratio of 28:72 in mass ratio, add 0.1% of 1010 antioxidant and 0.2% of 168 antioxidant in mass ratio, squeeze The outlet temperature conditions were 170°C, 175°C, 180°C, 185°C, 180°C, 175°C, and the injection molding temperature conditions were 195°C, 195°C, 190°C, 185°C, 180°C to obtain fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com