Method for preparing spring dextrin by aid of alpha amylase for hydrolyzing amylose starch

An amylose and alpha amylase technology, which is applied in the directions of medical preparations, applications, and pharmaceutical formulations of non-active ingredients to achieve mild conditions, fewer side reactions, and narrow distribution of product components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Preparation of spring dextrin

[0018] Dissolve 5 parts of 1g amylose into 10mL NaOH solution (90℃, 0.5mol / L), add 1L distilled water, adjust the temperature to 60℃, and adjust pH 6.0 with 2mol / L HCl. Then add 10U enzyme to each amylose solution, keep it at 60℃ for 1h, 2h, 3h, 4h, 5h, and finally add 5mol / L HCl solution to adjust the pH to below 3. The powder product of spring dextrin is obtained by spray drying.

Embodiment 2

[0019] Example 2 Color development of spring dextrin and iodine solution

[0020] Dissolve the spring dextrin prepared in Example 1 in distilled water, add iodine solution to develop color, and perform full-wavelength scanning, using the formula (1 / λ max =1.558×10 -3 +102.5×10 -4 (1 / )) can calculate the average degree of polymerization of spring dextrin. Spring dextrin hydrolyzed for 1h, 2h, 3h, 4h, 5h They are 36.6, 25.9, 14.7, 12.5 and 11.7 respectively.

Embodiment 3

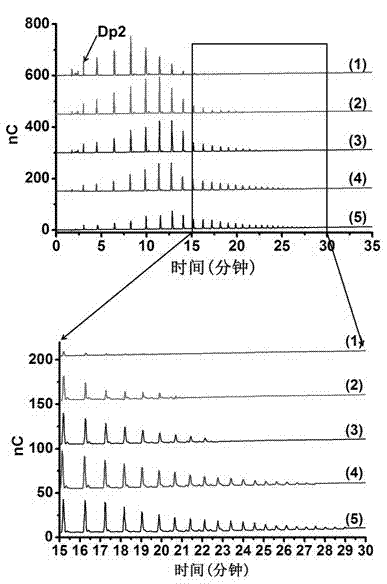

[0021] Example 3 Detection of the molecular weight distribution of spring dextrin by high performance anion chromatography

[0022] The powdered spring dextrin in Example 1 was detected by high performance anion chromatography. The detection conditions were Dionex ICS-500 chromatography system. The column model used was Dionex CarboPAC PA200 (250×4 mm ID); the detection mobile phase was 100mM sodium hydroxide Solution (eluent A), 100mM sodium hydroxide solution containing 600mM sodium acetate (eluent B); the elution gradient is 20% at 0 minutes, eluent B, and at 60 minutes, eluent B is 100%; The flow rate is 1 mL / min, and the sample load is 25 μL. The high-efficiency anion chromatogram of the product spring dextrin after different hydrolysis time is as follows figure 2 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com