Tornadic hot air underfeed automatic stoking quenching furnace

A quenching furnace and hot air technology, applied in quenching device, heat treatment equipment, heat treatment process control and other directions, can solve the problems of unsuitable control of quenching temperature and time, unimproved black smoke state, low fuel heat utilization rate, etc. Quenching heating effect, improving sealing and thermal insulation effect, increasing the effect of placing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

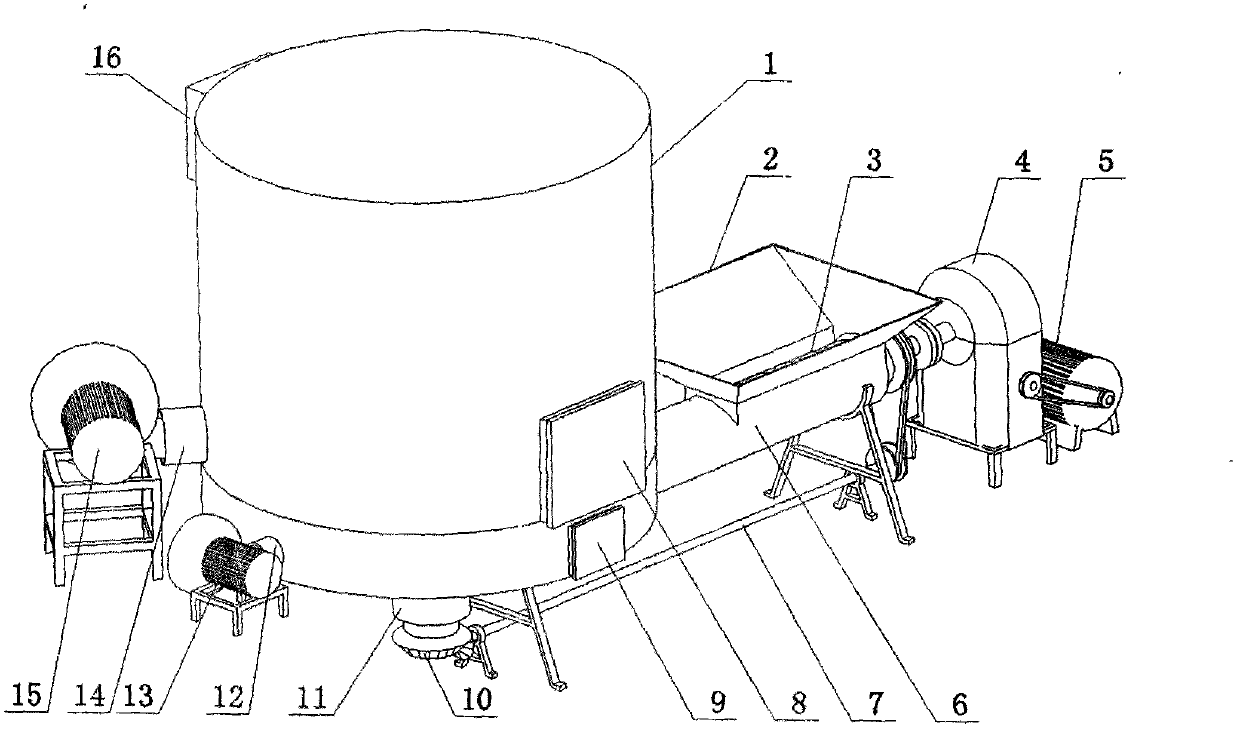

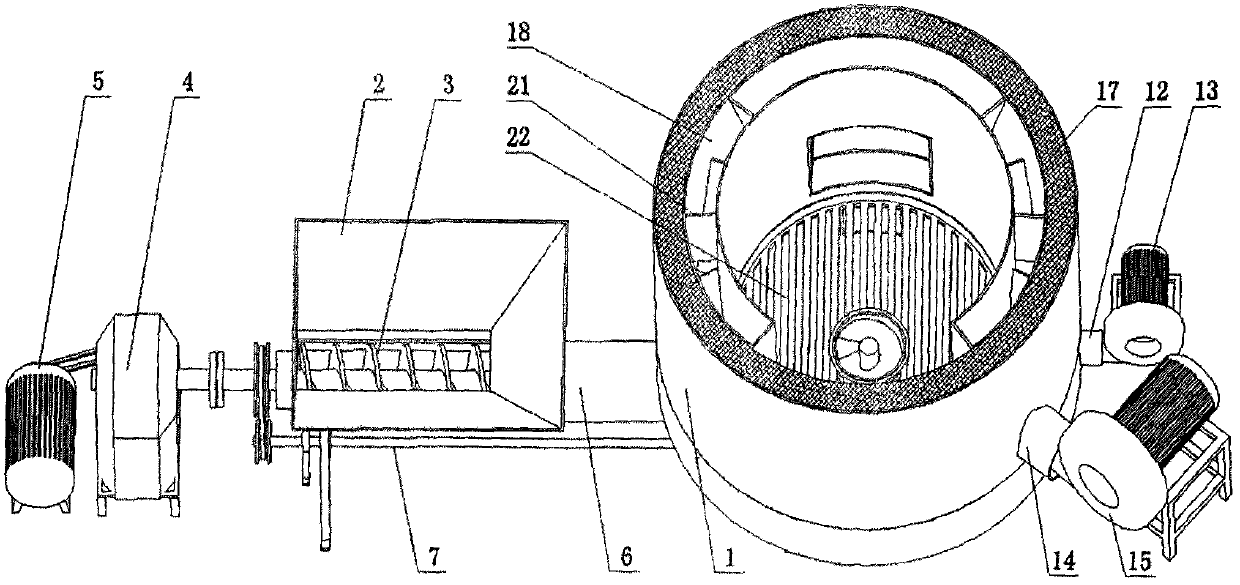

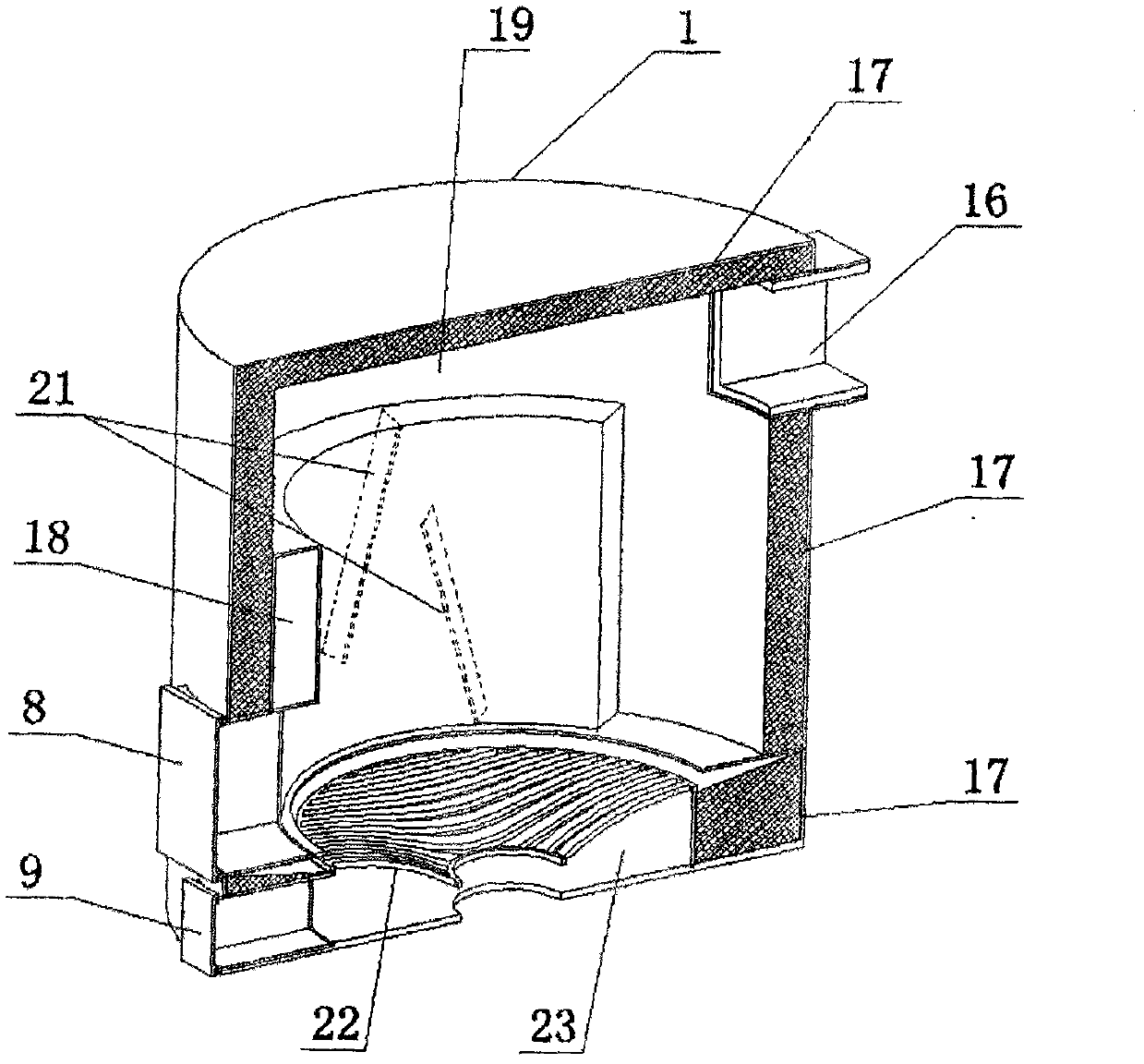

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a tornado hot air feed-down automatic coal-feeding quenching furnace includes a quenching furnace cavity and four coal-fired heaters that are distributed around the quenching furnace cavity and inject flames into the quenching furnace cavity. Described coal-fired heater comprises heater furnace body, and the outer layer of heater furnace body is iron plate 1, and refractory rock wool insulating material layer 17 is attached around heater furnace body and the inner side of top iron plate; The lower part is a cylindrical ash cavity 23, and the upper edge of the ash cavity 23 supports a trumpet-shaped furnace grate 22 with a coal feeding port in the center. The combustion chamber 19 is above the furnace grate 22; a "C" is arranged around the combustion chamber 19. Shaped air supply channel 18, ei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com