Flame retardant anti-bacterial composite modifier used in fiber field and preparation method thereof

A composite modifier and technology in the field, applied in the field of functional materials, can solve the problems of single performance of disinfectants and flame retardants, no functional composite discussion, etc., and achieve the effects of not easy to degrade, not easy to migrate, and lasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

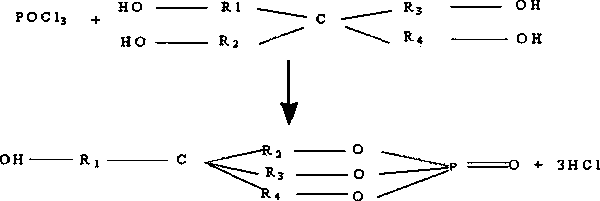

[0041] A method for preparing a flame-retardant and antibacterial composite modifier used in the fiber field, the specific steps of which are:

[0042] (1) Preparation of phosphoric acid ester:

[0043] Take 34g (0.28mol) of pentaerythritol in how many grams of POCl 3 Stir in a three-necked flask, heat to 75°C, react for 24h, cool and filter, wash with dichloromethane, dry to constant weight and recrystallize with glacial acetic acid, add 200ml of deionized water into a three-necked flask, and react with 100°C 2h, filtered and dried to obtain solid B0.28mol (50.4g).

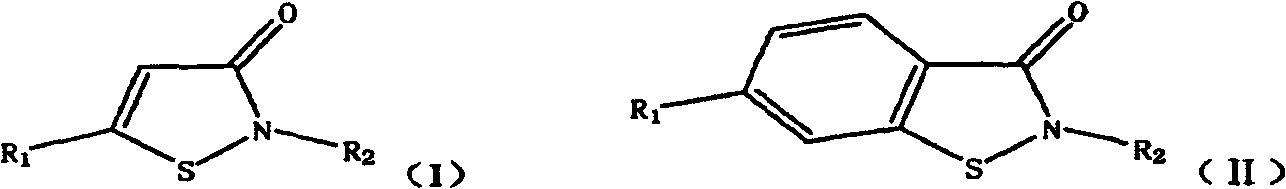

[0044] (2) Preparation of flame retardant and antibacterial composite materials:

[0045] Take 0.28mol of B, C, D and a three-neck flask, add 16.8g of concentrated sulfuric acid and 5.11g of DCC / DIC as a catalyst, heat up to 70-200°C, react for 3-10 hours, cool, filter and dry to obtain solid E.

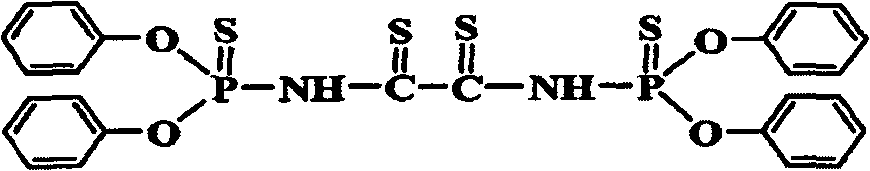

[0046] The obtained composite material of the present invention has the following characteristics:

[0047] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com