Method and device for improving thermal circulation efficiency

A thermal cycle and nuclear power plant technology, applied in steam engine installations, heat pumps, steam applications, etc., can solve the problems of waste of water resources and energy, low thermal cycle efficiency, poor economic benefits, etc., and achieve reduced power consumption and no noise Pollution, the effect of solving the problem of efficient utilization of exhaust steam waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

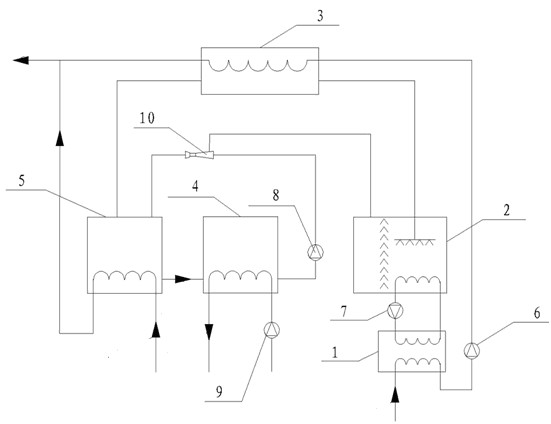

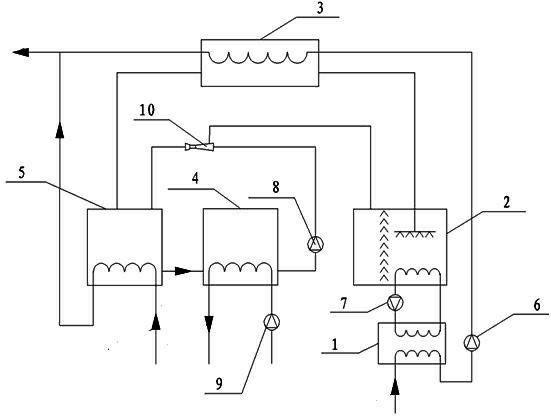

[0023] The method of this embodiment for improving the thermal cycle efficiency of a thermal power plant or a nuclear power plant is to enter the exhaust steam from the steam turbine into the condenser 1, and exchange heat with the refrigerant water in the condenser 1, and the refrigerant water that obtains heat passes through the The refrigerant water circulating pump 7 is pumped into the evaporator 2 to cool down, and the condensed and cooled exhaust steam is pumped into the condenser 3 through the condensing circulating water pump 6, and the heat is fed back in the condenser 3 to heat up, and the heated condensate passes through The pipeline flows into the steam generator of the nuclear power plant or the boiler of the thermal power plant to raise the temperature and pressurize to realize the Rankine cycle; the high-temperature steam from the blowdown of the boiler or the exhaust gas from the steam turbine enters the generator 5 to compensate for the insufficient steam in the...

Embodiment 2

[0028] The difference between the method for improving thermal cycle efficiency in thermal power plants or nuclear power plants of this embodiment and the method for improving thermal cycle efficiency in thermal power plants or nuclear power plants in Embodiment 1 is that the heat-absorbing fluid in the absorber uses exhaust steam The condensed water gets heat from the absorber and flows into the steam generator of the nuclear power plant or the boiler of the thermal power plant.

[0029] The difference between the device for improving thermal cycle efficiency in a thermal power plant or nuclear power plant of this embodiment and the device for improving thermal cycle efficiency in a thermal power plant or nuclear power plant in Embodiment 1 is that the heat-absorbing fluid side of the absorber 4 passes through the cycle The pump 9 and the pipeline are connected with the condensate pipeline.

[0030] In summary, the present invention organically combines the reverse Carjo cycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com