Pulse driving power supply of high-power semiconductor laser

A pulse drive, semiconductor technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problem of small output current and achieve the effect of good edge characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

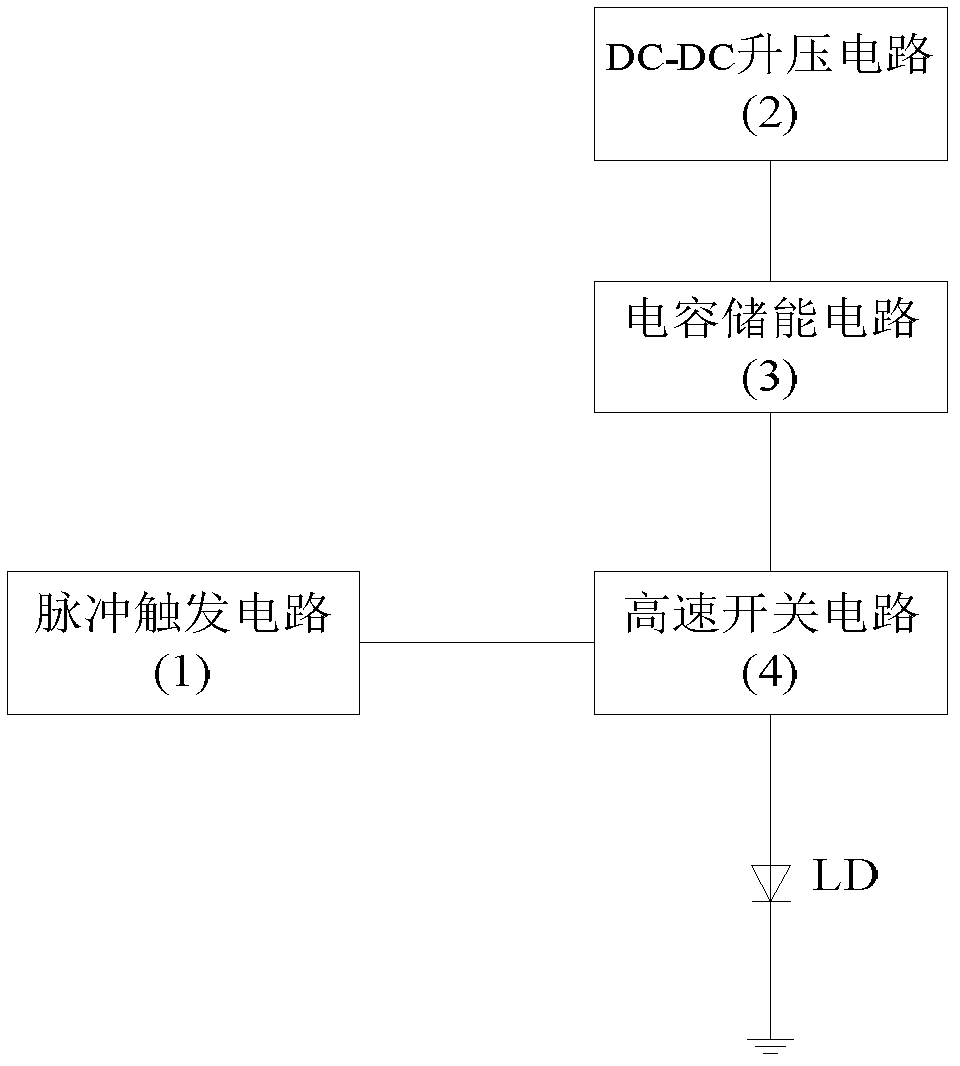

[0022] Embodiment 1 illustrates the overall structure of the present invention in conjunction with the accompanying drawings

[0023] The high-power semiconductor laser pulse drive power supply of the present invention is composed of four parts: a pulse trigger circuit 1, a DC-DC boost circuit 2, a capacitor energy storage circuit 3, and a high-speed switch circuit 4. The structural block diagram is as follows figure 1 shown. Wherein the DC-DC step-up circuit 2 generates a high-voltage direct current voltage, which is connected to the capacitor energy storage circuit 3. The capacitor energy storage circuit stores energy and is connected to the high-speed switch circuit 4. Under the control of the signal, the energy stored in the capacitor energy storage circuit 3 is released, so that a narrow pulse with a large current value is obtained on the load LD.

Embodiment 2

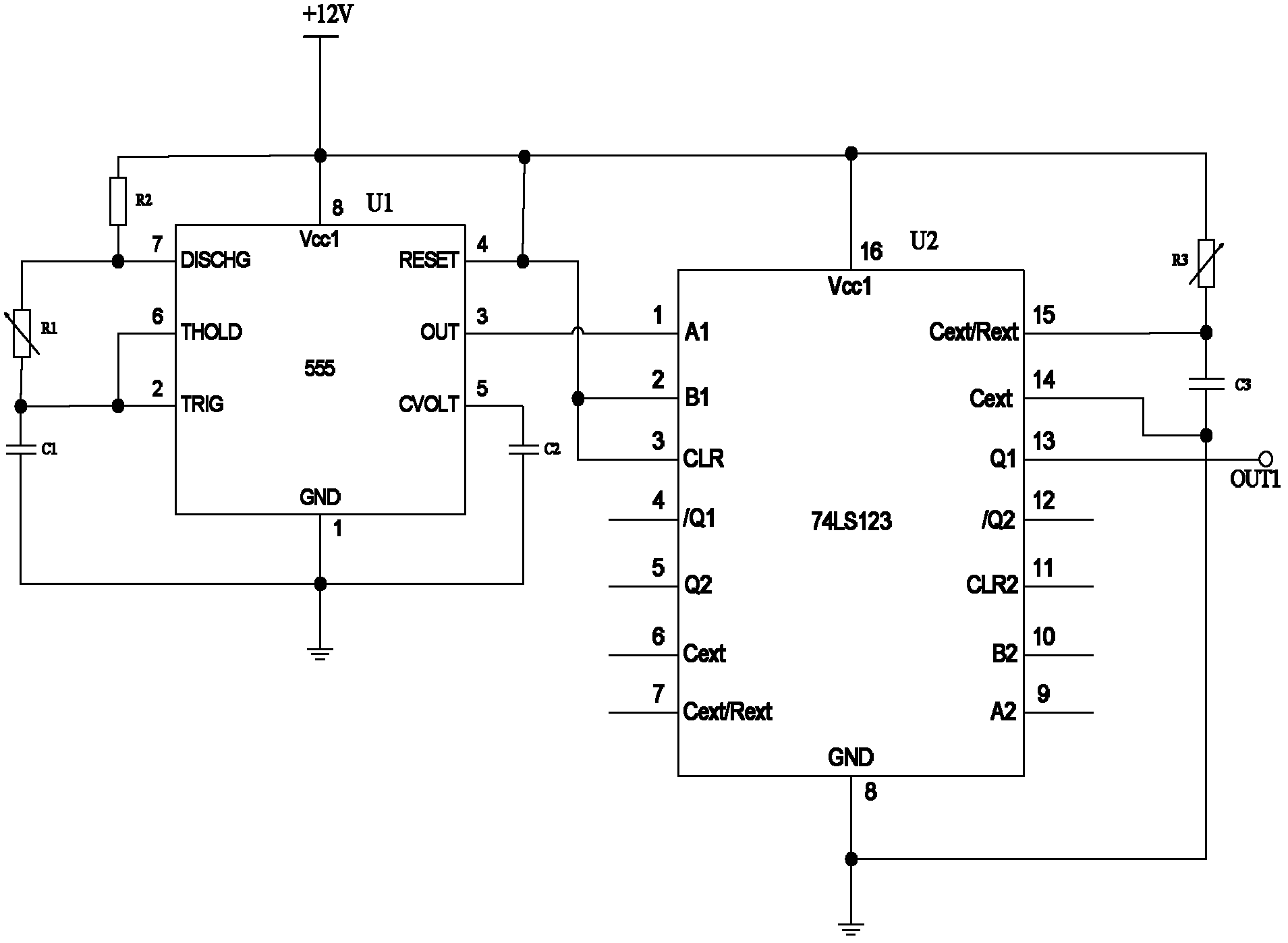

[0024] Embodiment 2 Pulse Trigger Circuit 1

[0025] Such as figure 2 As shown, pulse trigger circuit 1 includes: pin 1 of 555 chip U1 is grounded, one end of capacitor C1 and C2 is connected to pin 1 of 555 chip U1, the other end of C1 is connected to pin 2 of 555 chip U1, and the other end of C2 is connected to pin 1 of 555 chip U1. The 5 pins of the 555 chip U1 are connected, the 2 pins of the 555 chip U1 are connected with the 6 pins of the 555 chip U1, one end of the variable resistor R1 is connected with the 2 pins of the 555 chip U1, and the other end is connected with the 7 pins of the 555 chip U1. One end of resistor R2 is connected to pin 7 of 555 chip U1, and the other end is connected to pin 8 of 555 chip U1. Pin 8 of 555 chip U1 is connected to +12V power supply and connected to pin 4 of 555 chip U1. Pin 3 of 555 chip U1 is connected with pin 1 of 74LS123 chip U2, pin 16 of 74LS123 chip U2 is connected with pin 8 of 555 chip U1, pin 2 and pin 3 of 74LS123 chip U...

Embodiment 3D

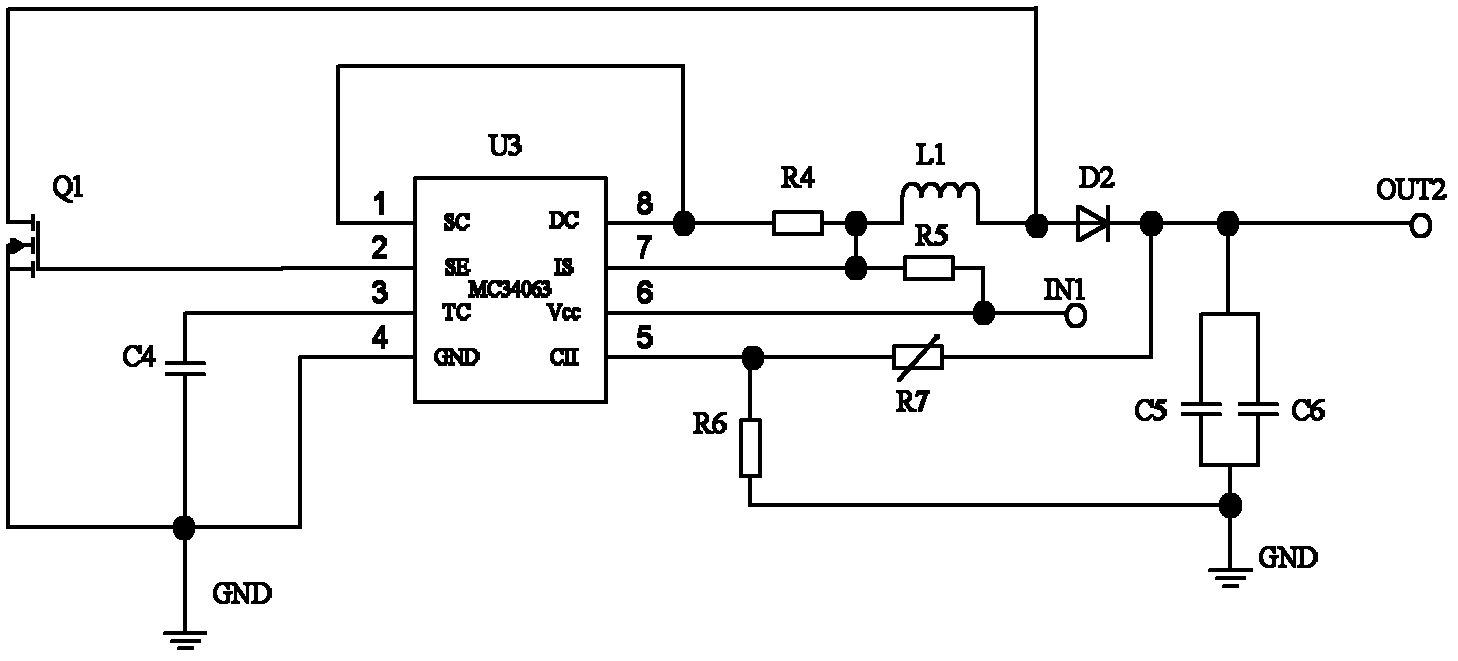

[0027] Embodiment 3 DC-DC boost circuit 2

[0028] Such as image 3As shown, the DC-DC boost circuit 2 includes: MC34063 chip U3’s pin 1 is connected to pin 8, pin 2 is connected to the gate of field effect transistor Q1, the source of Q1 is connected to ground GND and connected to one end of capacitor C4, and the other end of C4 One end is connected to pin 3 of MC34063 chip U3, and pin 4 of MC34063 chip U3 is connected to ground GND. Pin 8 of MC34063 chip U3 is connected to one end of resistor R4, and the other end of R4 is connected to pin 7 of MC34063 chip U3, and connected to one end of inductor L1, and the other end of inductor L1 is connected to the drain of field effect transistor Q1, and connected to the anode of diode D2 , the cathode of diode D2 is connected to one end of variable resistor R7, and grounded through two parallel capacitors C5 and C6, and the other end of R7 is connected to pin 5 of MC34063 chip U3, and grounded through resistor R6. One end of resisto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com