Preparation method of photocatalytic photoconductive material

A photoconductive material and photocatalytic technology, which is applied in the field of preparation of photocatalytic photoconductive materials, can solve the problems of easy shedding light utilization rate, difficulty in separation and recovery, influence on catalytic activity, etc. Active, life-extending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

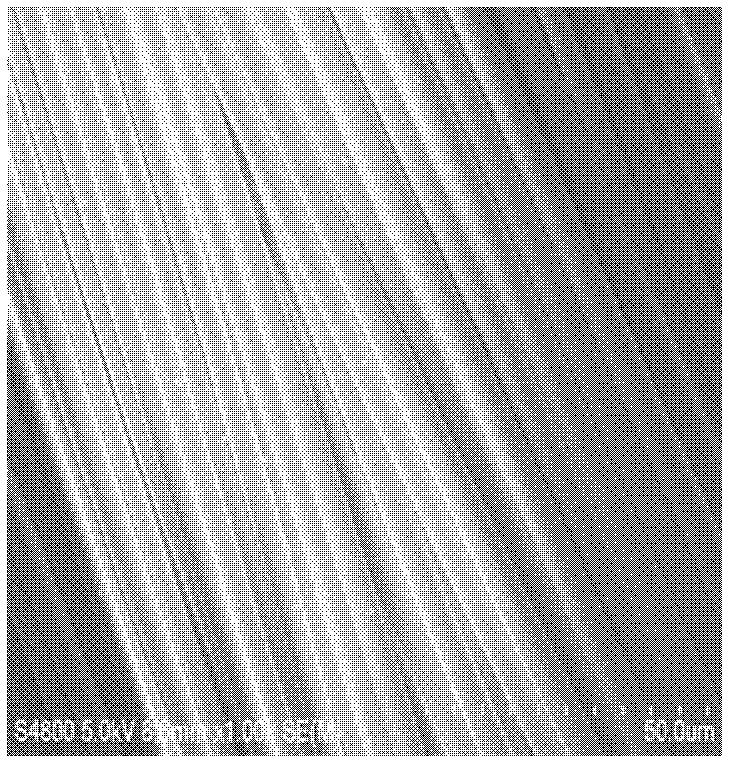

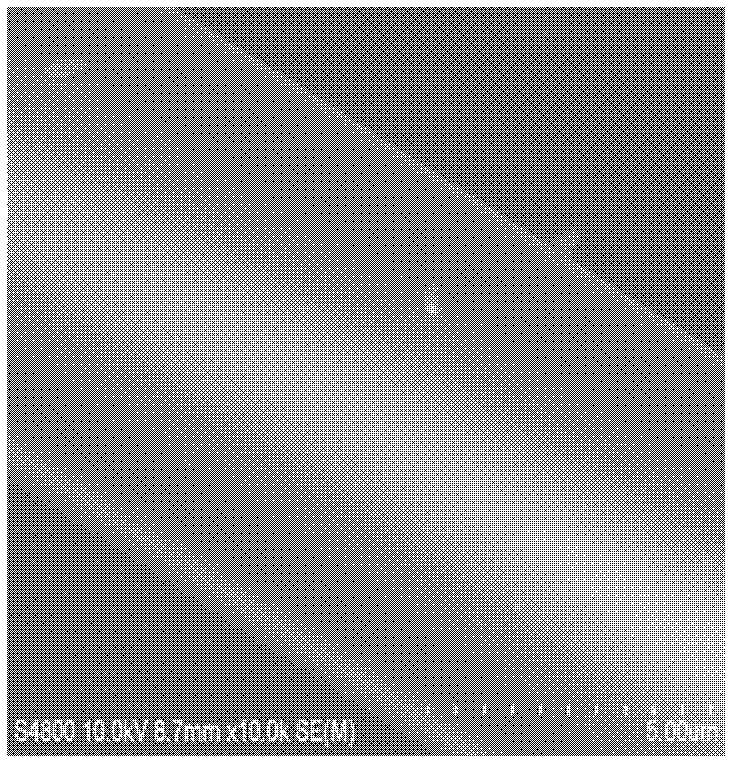

Image

Examples

Embodiment 1

[0028] 1) Prepare the original flooding solution

[0029] Add 16% butyl titanate and 5% diethanolamine to 79% absolute ethanol by volume and mix thoroughly to obtain a mixed solution, then add neodymium nitrate with 1% mass of the mixed solution to the mixed solution, and then fully stir Get the original flooding solution;

[0030] 2) Prepare drop solution

[0031] Add 8% distilled water to 92% absolute ethanol by volume, stir until fully mixed to obtain a dropwise solution;

[0032] 3) Preparation of nano-TiO 2 sol

[0033] Under vigorous stirring, drop the addition solution into the original flooding solution, and continue to stir vigorously to obtain transparent nano-TiO 2 Sol, wherein the volume percent of the dropping solution is 9%;

[0034] 4) Surface treatment

[0035] Ultrasonic cleaning and drying of the high-silica optical fiber, then immersing it in a strong alkali solution, and then ultrasonic cleaning and drying;

[0036] 5) Coating nano-TiO 2

[0037] I...

Embodiment 2

[0039] 1) Prepare the original flooding solution

[0040] Add 20% butyl titanate and 4% diethanolamine to 76% absolute ethanol by volume and mix thoroughly to obtain a mixed solution, then add neodymium nitrate with a mixed solution mass of 2% to the mixed solution, and then fully stir Get the original flooding solution;

[0041] 2) Prepare drop solution

[0042] Add 15% distilled water to 85% absolute ethanol by volume, and stir until fully mixed to obtain a dropwise solution;

[0043] 3) Preparation of nano-TiO 2 sol

[0044] Under vigorous stirring, drop the addition solution into the original flooding solution, and continue to stir vigorously to obtain transparent nano-TiO 2 Sol, wherein the volume percentage of the dropping liquid is 10%;

[0045] 4) Surface treatment

[0046] Ultrasonic cleaning and drying of the high-silica optical fiber, then immersing it in a strong alkali solution, and then ultrasonic cleaning and drying;

[0047] 5) Coating nano-TiO 2

[00...

Embodiment 3

[0050] 1) Prepare the original flooding solution

[0051] Add 22% butyl titanate and 6% diethanolamine to 72% absolute ethanol by volume and mix thoroughly to obtain a mixed solution, then add neodymium nitrate with a mixed solution mass of 3% to the mixed solution, and then fully stir Get the original flooding solution;

[0052] 2) Prepare drop solution

[0053] Add 10% distilled water to 90% absolute ethanol according to the volume ratio, stir until fully mixed to obtain the drop solution;

[0054] 3) Preparation of nano-TiO 2 sol

[0055] Under vigorous stirring, drop the addition solution into the original flooding solution, and continue to stir vigorously to obtain transparent nano-TiO 2 Sol, wherein the volume percentage of the dropping solution is 8%;

[0056] 4) Surface treatment

[0057] Ultrasonic cleaning and drying of the high-silica optical fiber, then immersing it in a strong alkali solution, and then ultrasonic cleaning and drying;

[0058] 5) Coating nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com