Preparation method of activated carbon supported ferrous heterogeneous Fenton's reagent oxidation catalyst

A heterogeneous Fenton, oxidation catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve difficult filtration separation, increase the difficulty of process operation , increase the cost of wastewater treatment and other issues, to achieve the effect of simplifying the treatment process, improving the efficiency of source utilization, and being easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

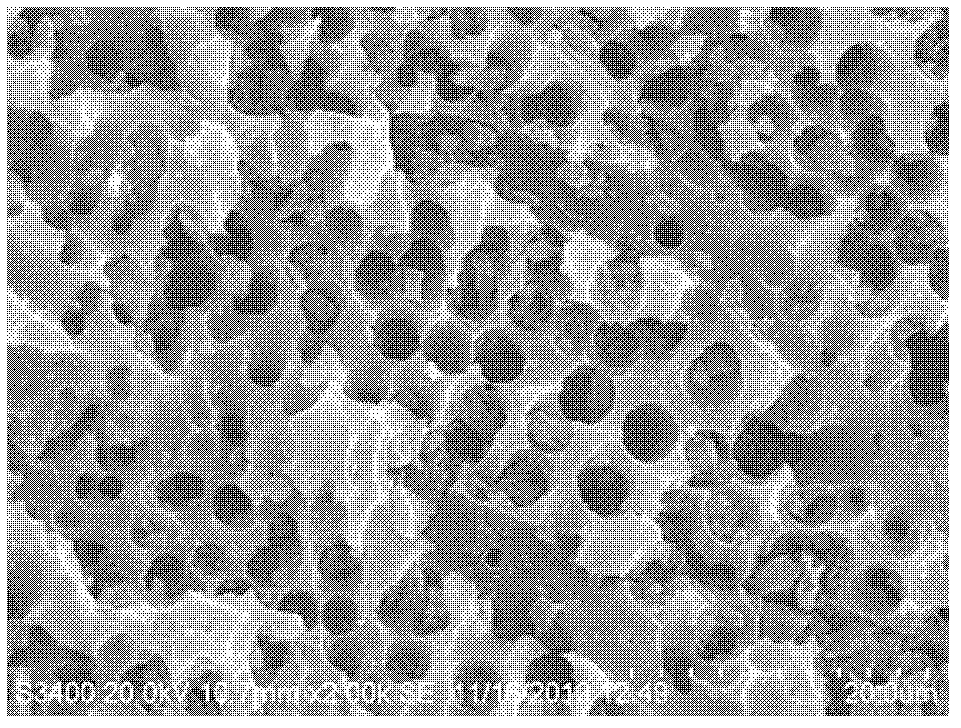

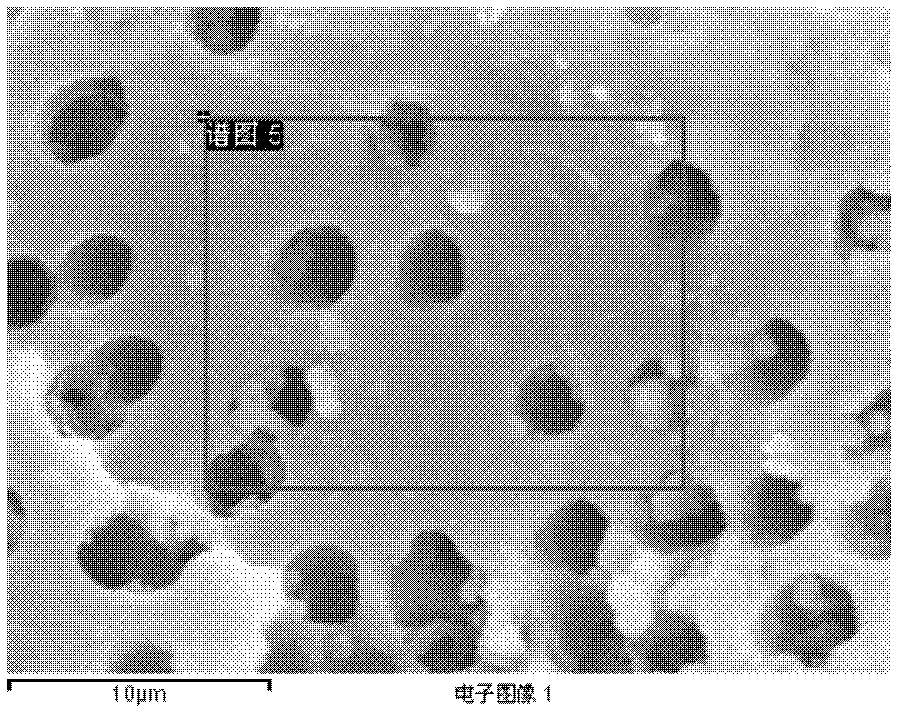

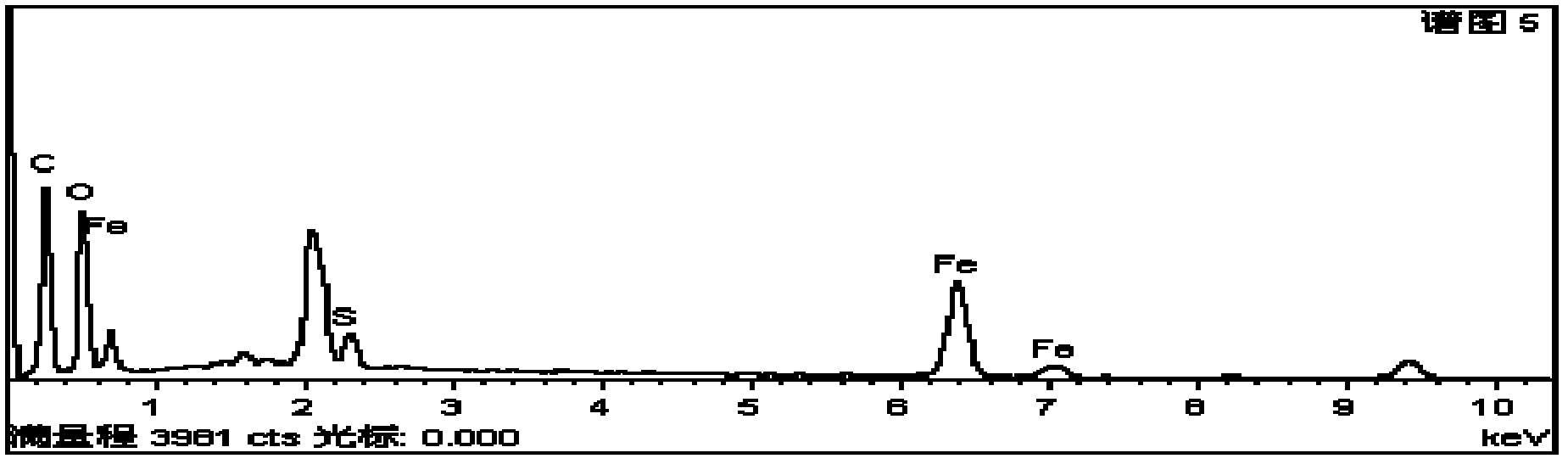

Image

Examples

Embodiment 1

[0037] First preparation 100mL concentration is the dilute sulfuric acid solution of 40% (mass fraction), at room temperature, under stirring condition, add 25g granular gac to soak in this solution, stirring speed is controlled at 150 rpm, after soaking time 24 hours, filter. The filtered activated carbon is continuously washed with flowing tap water, and the pH value of the drain water is measured during cleaning. When the measured pH value is 5-6, the cleaning is stopped. Then, the cleaned activated carbon is put into an oven and heated at a temperature of 105°C. Let dry for 2 hours. Get the prepared concentration 8% (mass fraction) ferrous sulfate solution 50mL, under room temperature, stirring condition, add above-mentioned activated carbon through dry treatment, the ferrous ion in the solution and activated carbon surface active group generation substitution reaction; Controlled at 150 rpm, after the replacement reaction was carried out for 24 hours, it was filtered. Th...

Embodiment 2

[0039] First preparation 50mL concentration is the dilute hydrochloric acid solution of 40% (mass fraction), at room temperature, under stirring condition, add 12.5g granular gac to soak in this solution, stirring speed is controlled at 150 rpm, after soaking time 24 hours, filter. The filtered activated carbon is continuously washed with running tap water, and the pH value of the drain water is measured during cleaning. When the measured pH = 5-6, the cleaning is stopped. Then, the cleaned activated carbon is put into an oven and heated at a temperature of 105°C. Let dry for 2 hours. Get the prepared concentration 8% (mass fraction) ferrous sulfate solution 25mL, under room temperature, stirring condition, add above-mentioned activated carbon through dry treatment, the ferrous ion in the solution and activated carbon surface active group generation substitution reaction; Controlled at 150 rpm, after the replacement reaction was carried out for 24 hours, it was filtered. The ...

Embodiment 3

[0042] First preparation 100mL concentration is the dilute sulfuric acid solution of 40% (mass fraction), at room temperature, under stirring condition, add 25g granular gac to soak in this solution, stirring speed is controlled at 150 rpm, after soaking time 24 hours, filter. The filtered activated carbon is continuously washed with running tap water, and the pH value of the drain water is measured during cleaning. When the measured pH = 5-6, the cleaning is stopped. Then, the cleaned activated carbon is put into an oven and heated at a temperature of 105°C. Let dry for 2 hours. Get the prepared concentration 4% (mass fraction) ferrous sulfate solution 150mL, under room temperature, stirring condition, add the above-mentioned activated carbon through dry treatment, the ferrous ion in the solution and activated carbon surface active group generation substitution reaction; It was controlled at 150 rpm, and after the displacement reaction was carried out for 48 hours, it was fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com