Method for recycling rhenium from copper smelting waste acid

A technology for copper smelting and waste acid, applied in the direction of improving process efficiency, can solve problems such as complex conditions, waste, pollution of environmental resources, etc., and achieve the effect of obvious economic value and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

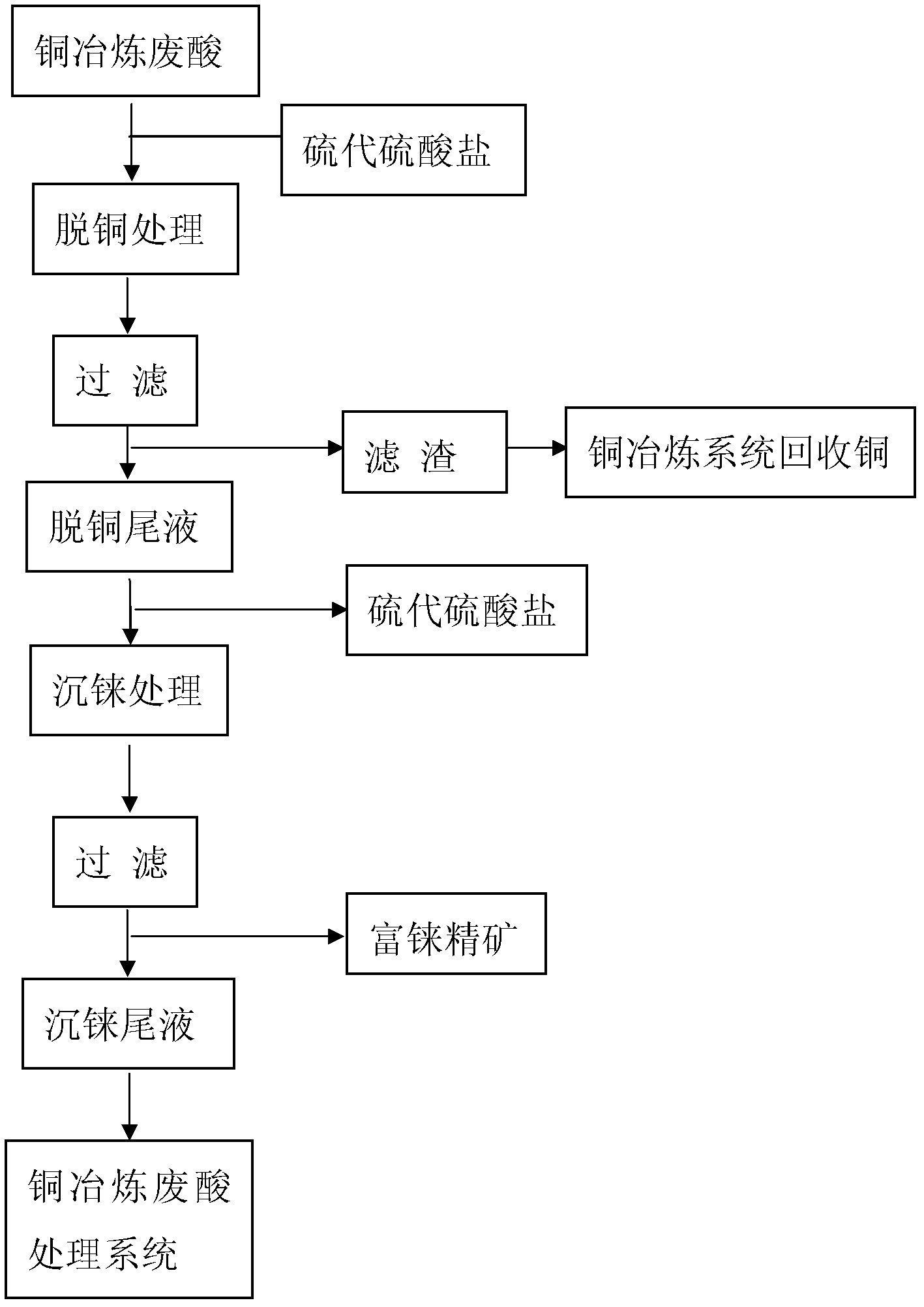

Method used

Image

Examples

Embodiment 1

[0041] Direct extraction of rhenium from waste acid: take 1 liter of waste acid from copper smelting, waste acid components: Cu 0.1g / L, As0.9g / L, Re 0.018g / L, H 2 SO 4 100g / L. Put 1 liter of waste acid in a container, turn on the stirrer, heat the waste acid to 70°C, add 5 g of sodium thiosulfate to 1 liter of waste acid, react for 1 hour, filter, and separate solid and liquid to obtain rhenium-rich concentrate.

[0042] The filtrate is copper removal tail liquid, tail liquid composition: Cu 0.005g / L, As 0.8g / L, Re0.0005g / L, H 2 SO 4 100g / L. The filter cake contains 14.6% copper and 3.1% rhenium. Calculated according to the composition of waste acid stock solution and rhenium extraction tail liquid, the recovery rate of rhenium is 97%.

Embodiment 2

[0044](1) Pre-decoppering of waste acid: take 1 liter of waste acid from copper smelting, components of waste acid: Cu 0.5g / L, As0.8g / L, Re 0.015g / L, H 2 SO 4 150g / L. Put 1 liter of waste acid in a container, turn on the stirrer, heat the waste acid to 65°C, add a corresponding amount of sodium thiosulfate according to 1.7 times the amount of copper in the waste acid, react for 1 hour, filter, solid-liquid After separation, the copper-removing tail liquid enters the rhenium extraction process, and the filter residue can be returned to the copper smelting system.

[0045] The filtrate is copper removal tail liquid, tail liquid composition: Cu 0.05g / L, As 0.8g / L, Re0.015g / L, H 2 SO 4 150g / L. The filter cake contains 55.14% copper and 0.008% rhenium. Calculated according to the components of waste acid stock solution and decopper tail liquid, the copper recovery rate is 90%, the rhenium recovery rate is 100%, and arsenic does not precipitate during the copper removal proce...

Embodiment 3

[0050] (1) Pre-decoppering of waste acid: take 1 liter of waste acid from copper smelting, the composition of waste acid: Cu 1.5g / L, As1.09g / L, Re 0.022g / L, H 2 SO 4 300g / L. Put 1 liter of waste acid in a container, turn on the stirrer, heat the waste acid to 80°C, add the corresponding amount of sodium thiosulfate according to twice the amount of copper in the waste acid, react for 1 hour, filter, and separate the solid and liquid , the decopper tail liquid enters the rhenium extraction process, and the filter residue can be returned to the copper smelting system.

[0051] The filtrate is copper removal tail liquid, tail liquid composition: Cu 0.038g / L, As 1.09g / L, Re0.021g / L, H 2 SO 4 300g / L. The filter cake contains 57.23% copper and 0.005% rhenium. Calculated according to the components of waste acid stock solution and decopper tail liquid, the copper recovery rate is 97.46%, the rhenium recovery rate is 95.4%, and arsenic does not precipitate during the copper remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com