Roofing thermal insulation and water resistance composite system and construction technology

A composite system and thermal insulation layer technology, applied in the field of roof thermal insulation and waterproof composite system and construction technology, can solve the problems of failing to achieve the designed thermal insulation effect, increasing the thermal conductivity of the thermal insulation layer, losing thermal insulation performance, etc. Remarkable waterproof effect, good water resistance, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Clean the base surface so that the base surface is free of oil, loose matter, etc., and wet the base until saturated but without clear water;

[0054] (2) Apply cement-based permeable crystalline waterproof paint on the damp base surface treated in step (1), and apply two layers evenly, that is, the base surface waterproof layer;

[0055] This embodiment is a rigid waterproof coating made of Portland cement and refined quartz sand as the base material, mixed with active mineral powder. It is prepared by simply mixing active mineral micropowder. The weight of described Portland cement or ordinary Portland cement and refined quartz sand is 1:3;

[0056] In this embodiment, the average particle size of ultrafine mineral powder is less than 5 μm, and the specific surface area is 2.0-4.5 m 2 / g. The doping amount of the superfine mineral micropowder is 2.5% of the weight of the base material.

[0057] (3) After the base surface waterproof layer in step (2) is dry and...

Embodiment 2

[0087] Implementation steps are the same as in Example 1.

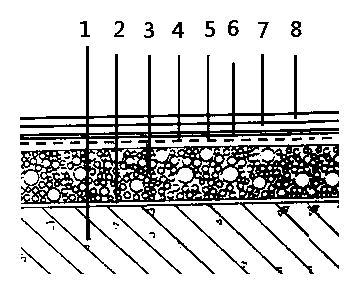

[0088] as attached figure 1 As shown, the roof system is mainly composed of base layer 1, base surface waterproof layer 2, expanded vitrified microbead insulation layer 3, anti-crack protection layer 4, flexible waterproof layer 7, leveling layer 7 and finish layer 8. First of all, make sure that the base is firm and flat, without hollowing, and the base surface should be cleaned without oil, mold release agent, floating ash, loose matter and other stains; defects on the base surface should be repaired in advance, and protrusions should be knocked out; Make oblique or arc angle. Before construction, wet the substrate to saturation but without clear water. Use a brush or roller to evenly apply the cement-based permeable crystalline waterproof slurry to the treated substrate. Keeping the substrate moist can help the slurry penetrate into the substrate. Generally, two coats need to be applied evenly. After the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com