Antioxidation collagen active membrane containing plant extract and preparation method for antioxidation collagen active membrane

A plant extract and collagen technology, applied in the field of edible film blending modification, to achieve the effect of eliminating harmful free radicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

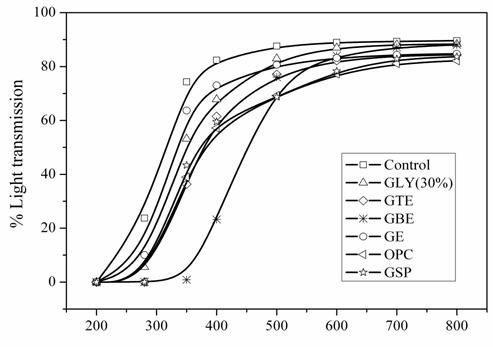

[0028] (1) Weigh 3g of fish skin collagen and dissolve it with 30ml of distilled water under stirring at 45°C to prepare a collagen aqueous solution.

[0029] (2) Weigh 1mg of grape seed extract (ginger extract, ginkgo leaf extract, green tea extract), dissolve it with 70ml distilled water at room temperature ultrasonically, filter with filter paper, and keep the filtrate at -20°C for use. (The extract is directly purchased from Ningbo Chinese Medicine Pharmaceutical Co., Ltd., and is an aqueous extract)

[0030] (3) Add 70 ml of the extract aqueous solution to 30 ml of the collagen aqueous solution, add 0.9 g of glycerin as a plasticizer, stir evenly, ultrasonically degas for 1 hour, and keep at 45°C. Pipette 20ml of casting solution each time and spread it on a 120mm×80mm×4mm plexiglass plate to form a film at a temperature of 20℃ and a film-forming time of 36h. Then, peel off the plexiglass plate to obtain antioxidant collagen Protein active membrane.

[0031] (4) Antioxidant te...

Embodiment 2

[0034] (1) Weigh 3g of collagen and stir and dissolve it with 30ml of distilled water at 45°C to prepare a collagen aqueous solution.

[0035] (2) Weigh 100 mg of grape seed extract (ginger extract, ginkgo leaf extract, green tea extract), dissolve it with 70 ml of distilled water at room temperature by ultrasonic, filter with filter paper, and keep the filtrate at -20°C for use.

[0036] (3) Add 70 ml of the extract aqueous solution to 30 ml of the collagen aqueous solution, add 0.9 g of glycerin as a plasticizer, stir evenly, ultrasonically degas for 1 hour, and keep at 45°C. Pipette 20ml of casting solution each time and spread it on a 120mm×80mm×4mm plexiglass plate to form a film at a temperature of 25℃ and a film-forming time of 38h. Then, peel off the plexiglass plate to obtain antioxidant collagen Protein active membrane.

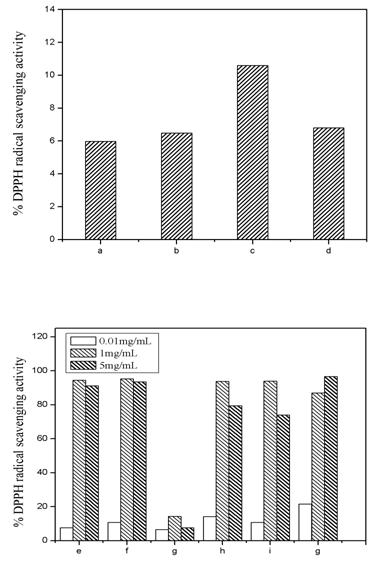

[0037] (4) Antioxidant test: The DPPH free radical scavenging ability of collagen membrane containing various extracts was measured, such as figure...

Embodiment 3

[0039] (1) Weigh 3g of fish skin collagen and stir and dissolve it with 30ml of distilled water at 45°C to prepare a collagen aqueous solution.

[0040] (2) Weigh 500mg of grape seed extract (ginger extract, ginkgo leaf extract, green tea extract), dissolve it with 70ml of distilled water at room temperature ultrasonically, filter with filter paper, and keep the filtrate at -20°C for use.

[0041] (3) Add 70 ml of the extract aqueous solution to 30 ml of fish skin collagen aqueous solution, add 0.9 g of glycerin as a plasticizer, stir evenly, ultrasonically degas for 1 hour, and keep warm at 45°C. Pipette 20ml of casting solution each time and spread it on a 120mm×80mm×4mm plexiglass plate to form a film at a temperature of 30℃ and a film forming time of 40h. Then, peel off the plexiglass plate to obtain antioxidant collagen Protein active membrane.

[0042] (4) Antioxidant test: The DPPH free radical scavenging ability of collagen membrane containing various extracts was measured, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com