High-voltage anode material for lithium ion batteries and method for preparing high-voltage anode material

A technology for lithium-ion batteries and positive electrode materials, applied in the field of high-voltage positive electrode materials and their preparation, to achieve the effects of shortening roasting time, improving electrochemical performance, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1mol cobalt oxalate, 2mol citric acid and 1mol LiH 2 PO 4 Sequentially add 650ml of deionized water, mix uniformly under electromagnetic stirring, heat at a constant temperature of 70°C while stirring, until the solution gradually forms a gel, stop heating, and dry the obtained gel at 100°C to form a dry gel. The glue was ground and mixed, and then placed in a tube furnace after tableting, and calcined at 400 °C for 8 hours in a high-purity nitrogen atmosphere. The obtained positive electrode material is pure phase lithium cobalt phosphate, and its structural composition is: LiCoPO 4 , the carbon content is 1.7%, and its initial discharge capacity is 128.0mAh / g.

Embodiment 2

[0022] 1mol lithium nitrate, 0.99mol cobalt nitrate, 0.01mol zinc acetate, 2mol citric acid and 1mol (NH 4 ) 2 HPO 4 Sequentially add 900ml of deionized water, mix uniformly under electromagnetic stirring, heat at a constant temperature of 75°C while stirring, until the solution gradually forms a gel, stop heating, and dry the obtained gel at 120°C to form a dry gel. The glue was ground and mixed uniformly, and then placed in a tube furnace after tableting, and calcined at 600 °C for 6 h in a high-purity argon atmosphere. The obtained positive electrode material has the following structural composition: LiZn 0.01 Co 0.99 PO 4 , the carbon content is 1.3%, and its initial discharge capacity is 145.6mAh / g.

Embodiment 3

[0024] 1mol LiNO 3 , 0.97mol cobalt acetate, 0.03mol zinc nitrate, 2mol citric acid and 1mol NH 4 H 2 PO 4 Sequentially add 850ml of deionized water, mix uniformly under electromagnetic stirring, heat at a constant temperature of 80°C while stirring, until the solution gradually forms a gel, stop heating, and dry the obtained gel at 150°C to form a dry gel. The glue was ground and mixed uniformly, and then placed in a tube furnace after tableting, and calcined at 800 °C for 4 h in a high-purity argon atmosphere. The obtained positive electrode material has the following structural composition: LiZn 0.03 Co 0.97 PO 4 , the carbon content is 0.6%, and its initial discharge capacity is 130.6mAh / g.

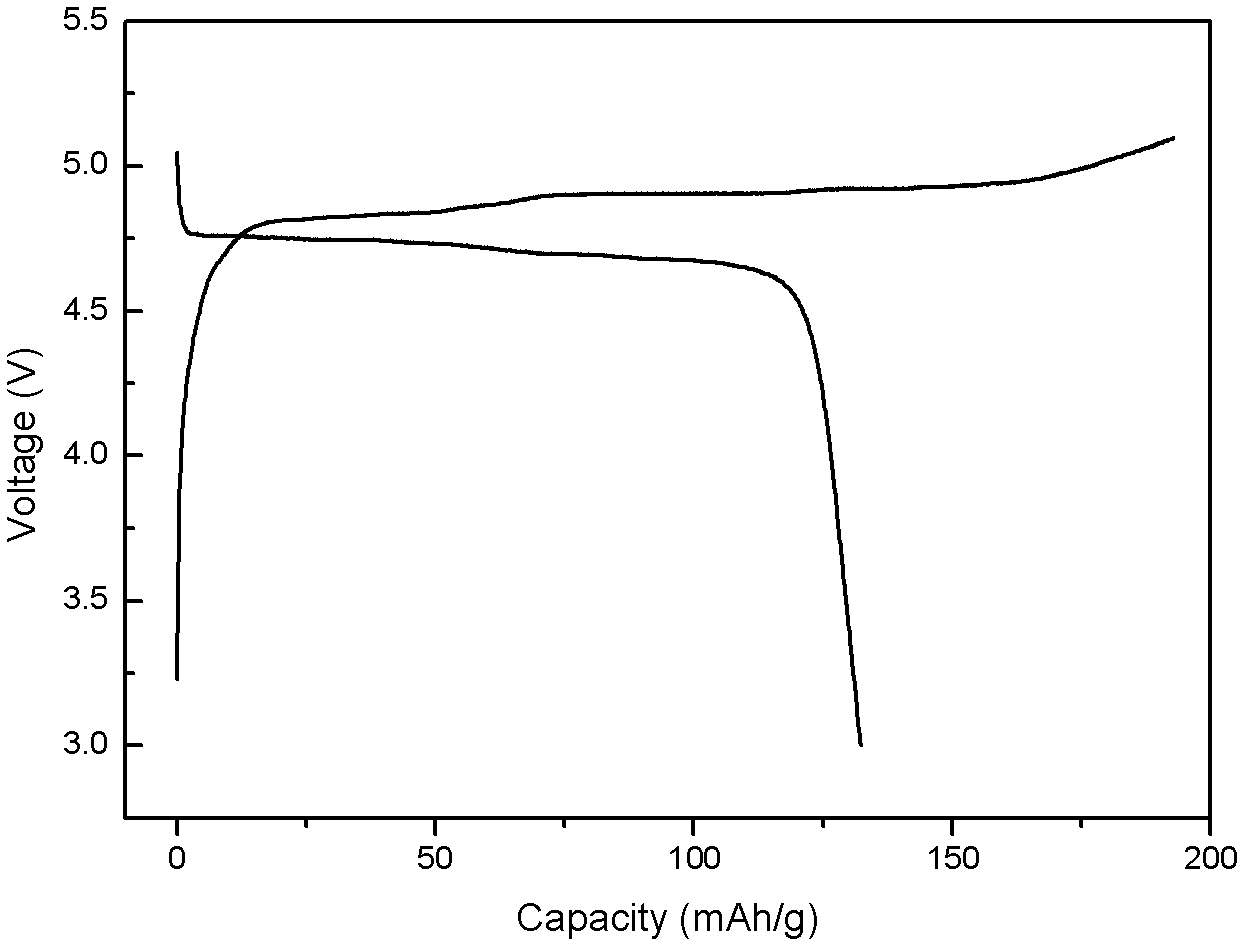

[0025] The first charge-discharge curve of the product obtained from Example 2 ( figure 1 ), it can be seen that the first discharge capacity of the sample is as high as 145.6 mAh / g.

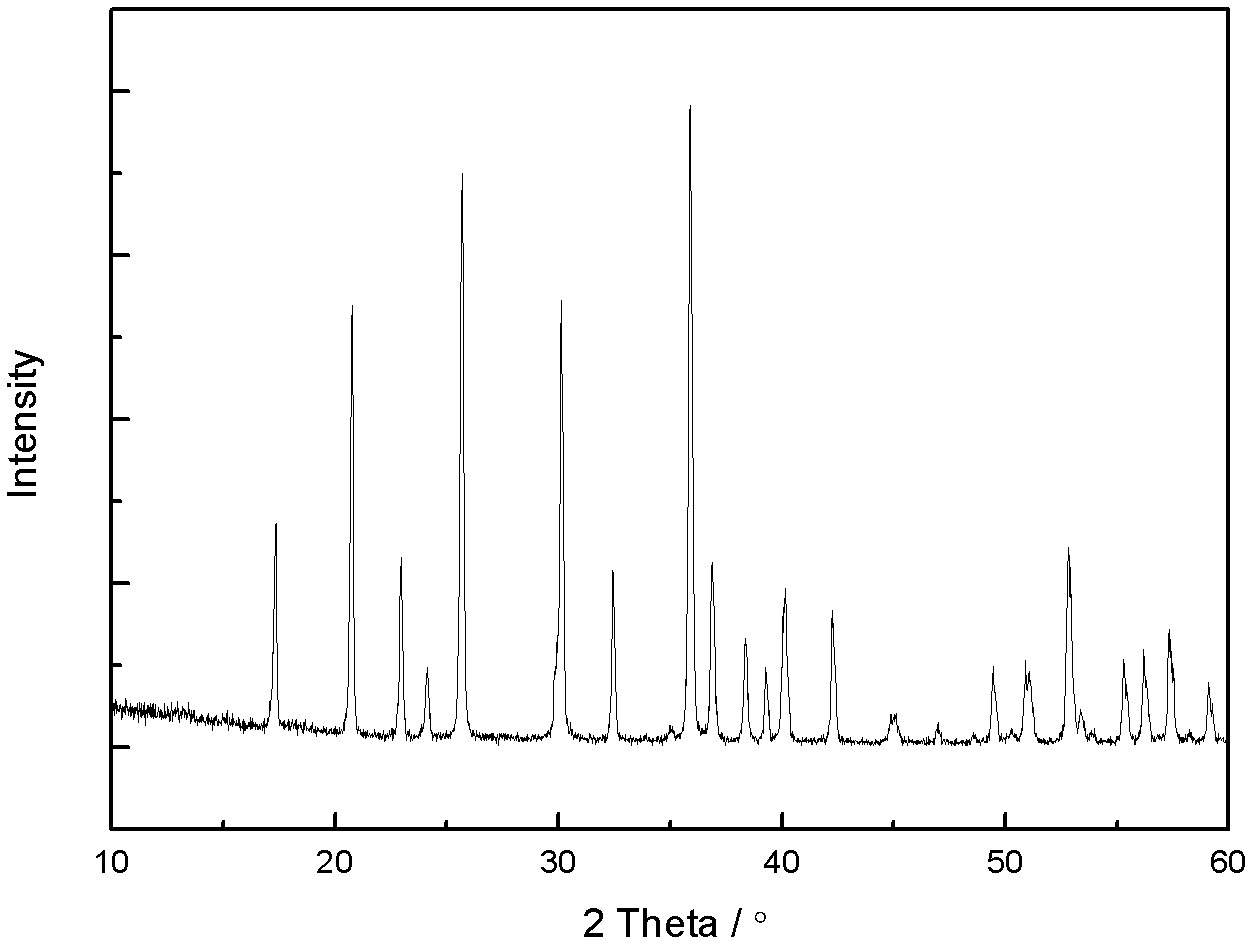

[0026] The XRD pattern of the product obtained from Example 2 ( figure 2 ), a small amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com