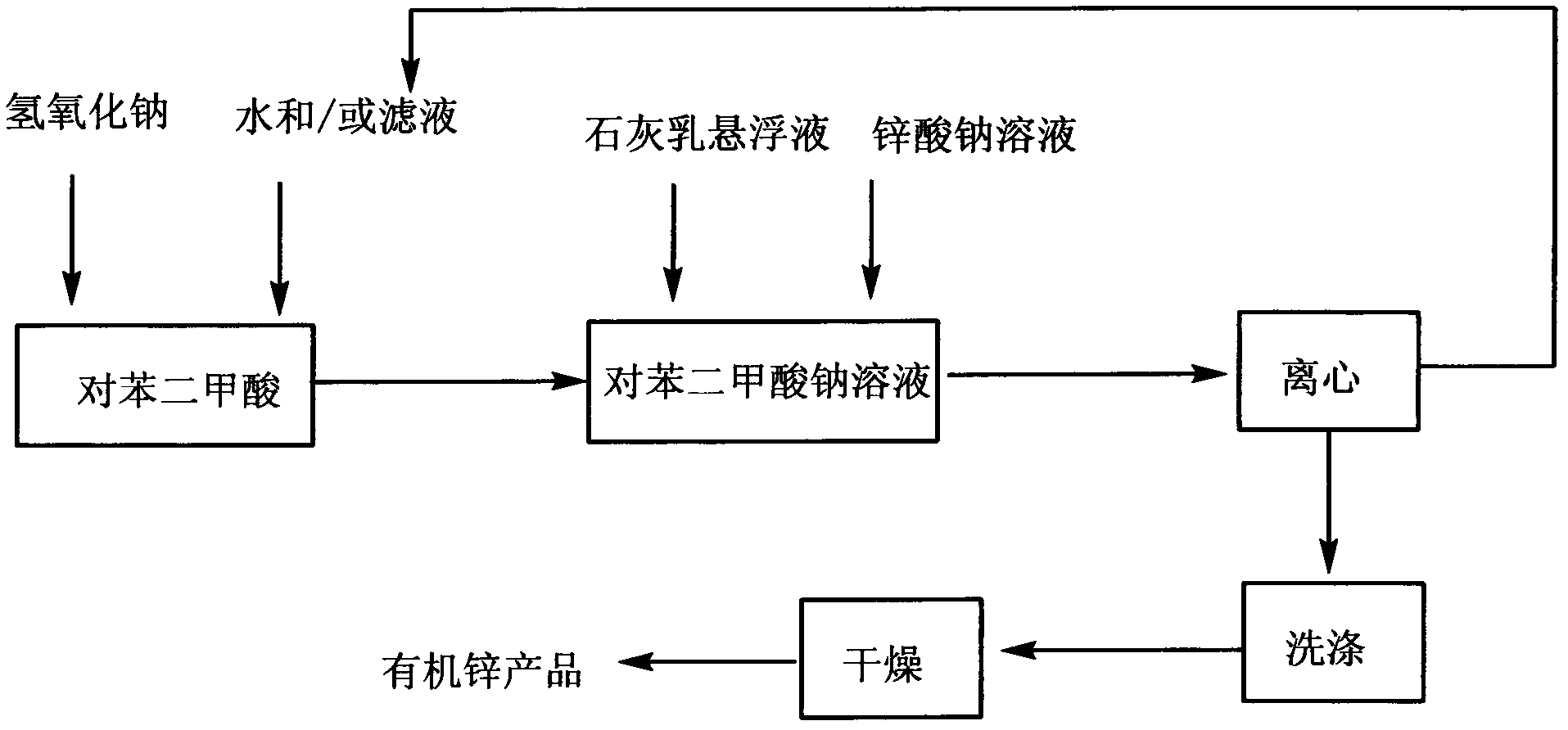

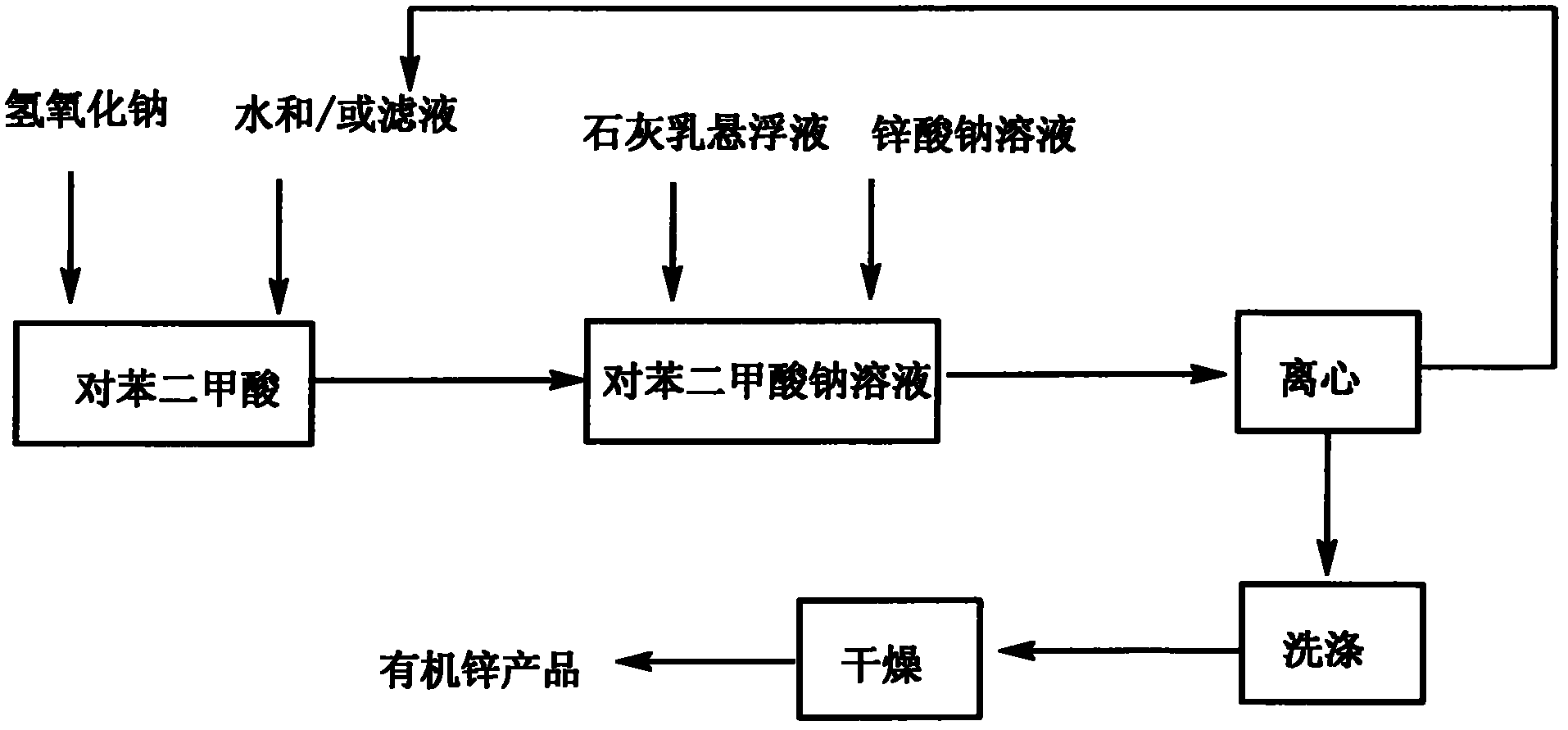

Method for preparing organic zinc by means of calcium analysis reactive crystallization

An organic zinc and crystallization technology, which is applied in organic chemistry, carboxylate preparation, etc., can solve the problems of coarse product particles, wastewater cannot be discharged directly, and unsatisfactory use, and achieve the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the reaction kettle, add 80 parts of terephthalic acid, add 160 parts of water, add 60 parts of sodium hydroxide, and stir. After the terephthalic acid is completely dissolved, add 60 parts of the saturated lime milk suspension, stir while adding the saturated lime milk suspension, the stirring speed is 60 rpm, and the addition is completed in 20 minutes. Let stand and settle for 60 minutes, add 60 parts of saturated sodium zincate solution, and stir while adding, the stirring rate is 30 rpm, and the addition is completed in 60 minutes. Allow to settle for 60 minutes. After centrifugal separation, the filtrate is sodium hydroxide solution, which is used to configure the next batch of sodium terephthalate solution. The product obtained by centrifugation, after washing and drying, is an organic zinc product.

Embodiment 2

[0023] In the reaction kettle, add 80 parts of terephthalic acid, add 120 parts of filtrate, add 10 parts of sodium hydroxide, and stir. After the terephthalic acid is completely dissolved, add 60 parts of the saturated lime milk suspension, stir while adding the saturated lime milk suspension, the stirring speed is 60 rpm, and the addition is completed in 20 minutes. Let stand and settle for 60 minutes, add 60 parts of saturated sodium zincate solution, and stir while adding, the stirring rate is 60 rpm, and the addition is completed in 30 minutes. Let it settle for 30 minutes. After centrifugal separation, the filtrate is sodium hydroxide solution, which is used to configure the next batch of sodium terephthalate solution. The product obtained by centrifugation, after washing and drying, is an organic zinc product.

Embodiment 3

[0025] In the reaction kettle, add 80 parts of terephthalic acid, add 120 parts of filtrate, add 80 parts of sodium hydroxide, and stir. After the terephthalic acid is completely dissolved, add 80 parts of the saturated milk of lime suspension, and stir while adding the saturated milk of lime suspension. The stirring speed is 60 rpm, and the addition is completed in 60 minutes. Let stand and settle for 60 minutes, add 80 parts of saturated sodium zincate solution, and stir while adding, the stirring rate is 60 rpm, and the addition is completed in 60 minutes. Allow to settle for 60 minutes. After centrifugal separation, the filtrate is sodium hydroxide solution, which is used to configure the next batch of sodium terephthalate solution. The product obtained by centrifugation, after washing and drying, is an organic zinc product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com