Electrolytic coloring technique of aluminum alloy cooker

An electrolytic coloring, aluminum alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of unsatisfactory color effect, affecting the appearance of aluminum alloy cookware, etc., and achieve the effect of improving aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

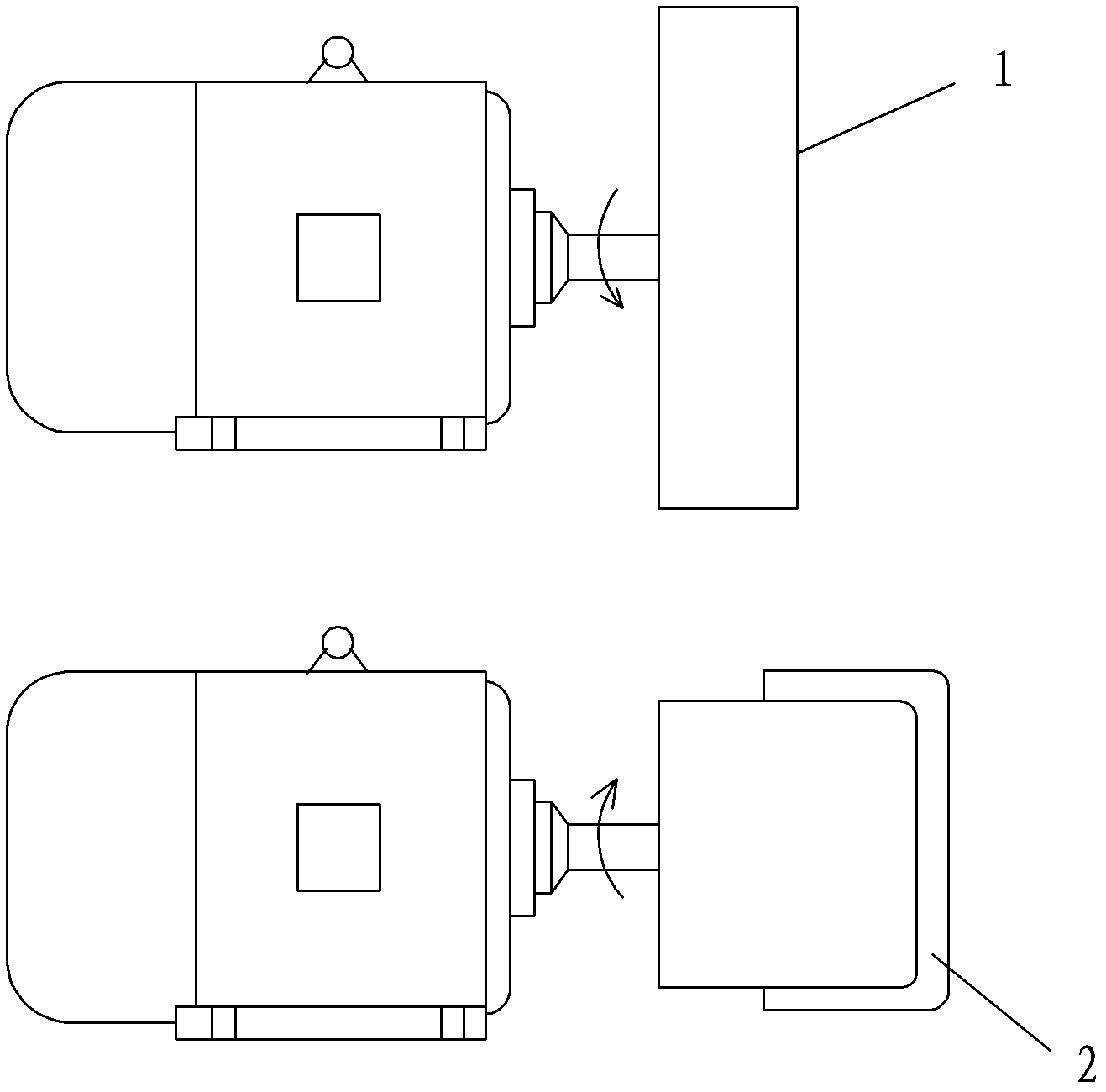

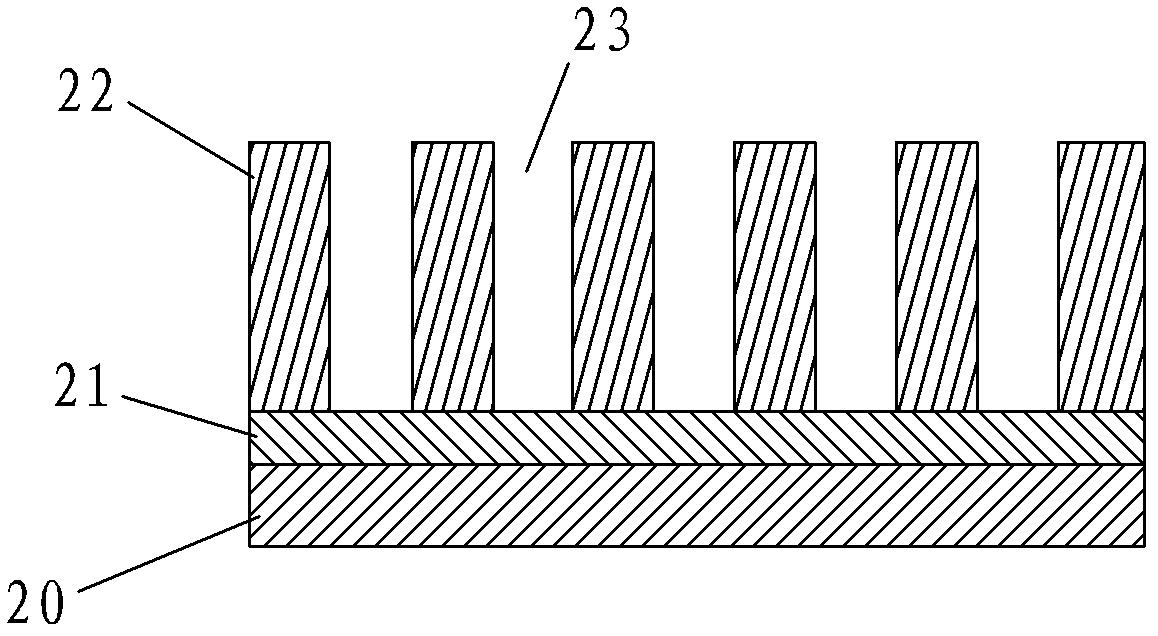

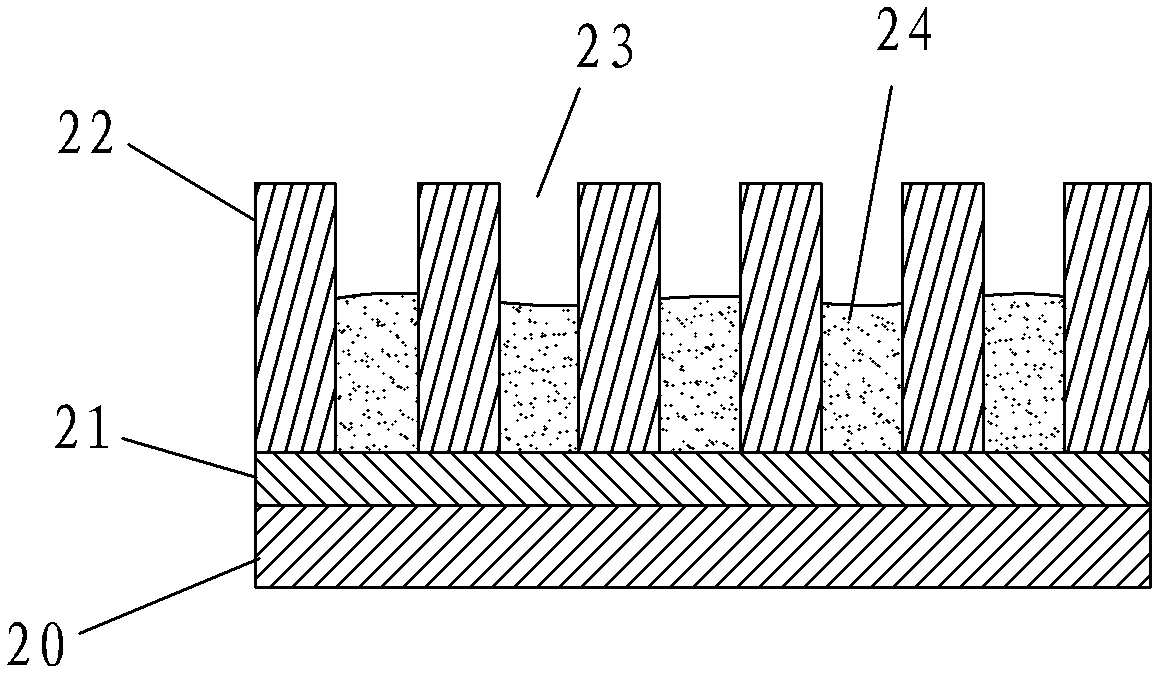

[0018] An electrolytic coloring process for aluminum alloy cookware, comprising the following steps: 1), polishing, such as figure 1 As shown, the surface of the workpiece 2 to be processed is polished mechanically, so that the surface of the workpiece 2 reaches the mirror brightness. The abrasive type used for polishing is ultrafine powder liquid wax, and the polishing wheel 1 is a flannelette wheel. The peripheral speed in the polishing process is 20~100m / s, pressure 0.5~4kg / cm 2 , the polishing time is 0.5~5min, and a smooth barrier layer 21 is formed on the surface of the workpiece 2 after polishing; 2) Cleaning, using low-pressure rotary stepping jet cleaning technology, using a degreasing agent with high cleaning power and high-efficiency surface-active cleaning agent Clean the surface of the polished workpiece 2, and maintain the mirror effect of the workpiece 2 while cleaning the surface of the workpiece 2; 3), oxidize the workpiece 2 with a smooth surface obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com