Method for preparing self-healing super-hydrophobic coating by means of spraying technology

A super-hydrophobic coating and self-repairing technology, which is applied in coatings, devices for coating liquid on the surface, etc., to achieve good self-cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

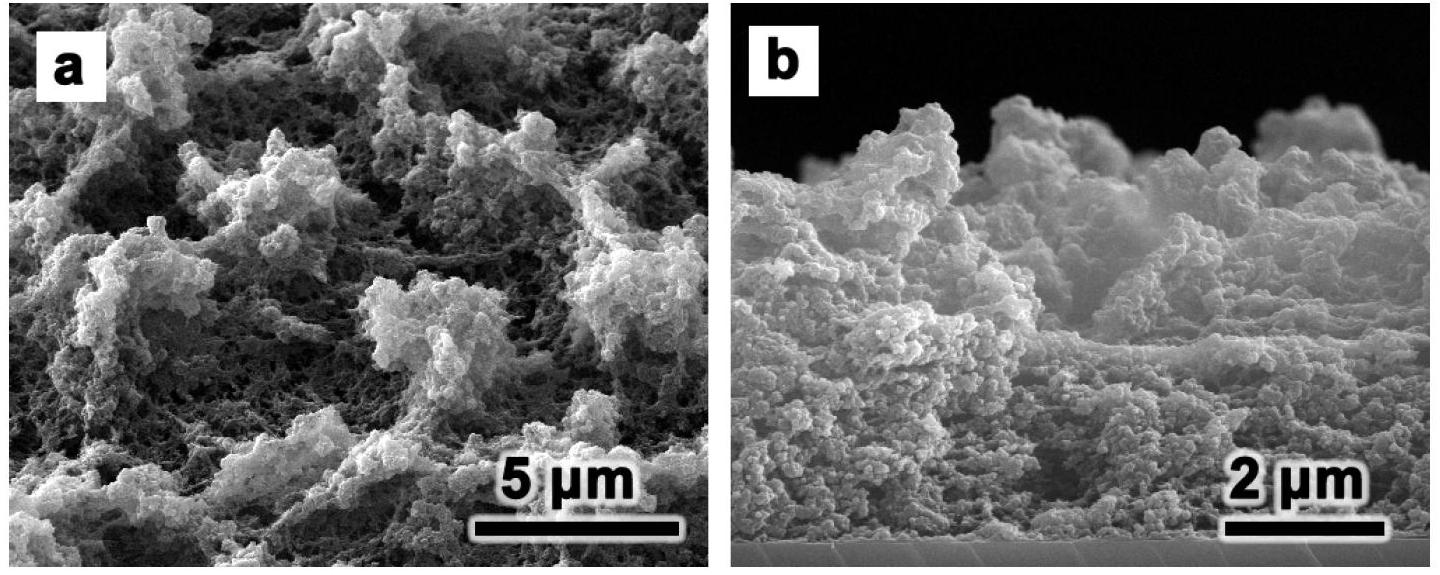

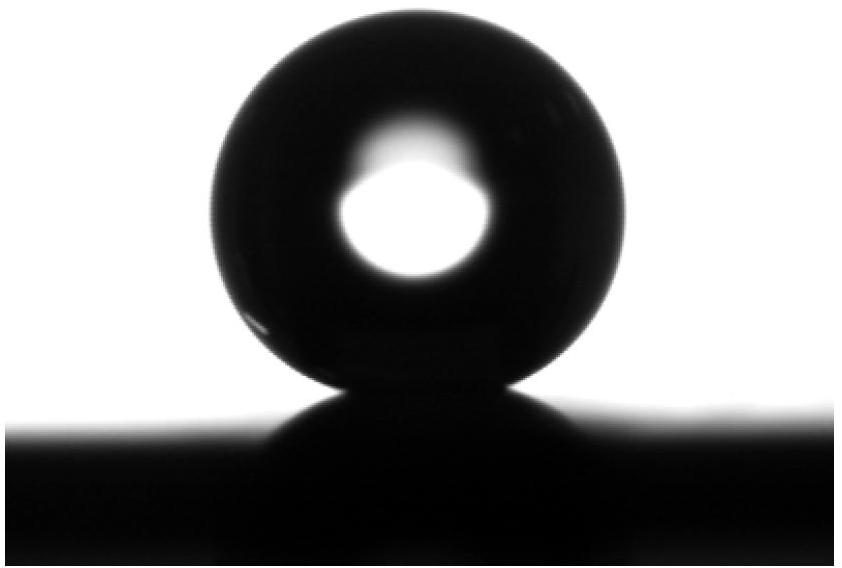

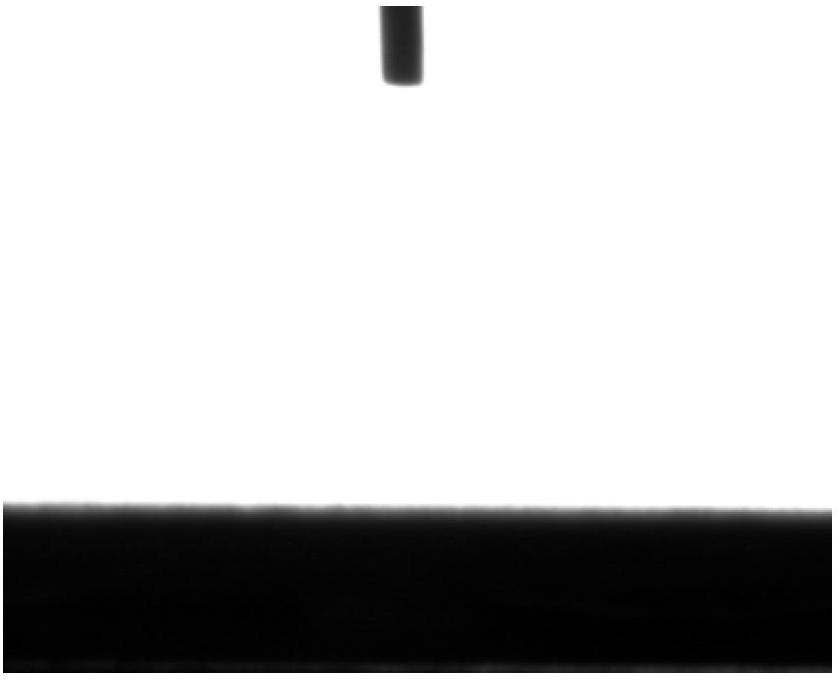

Image

Examples

Embodiment 1

[0029] (1) Treatment of the substrate:

[0030] Spray the silicon wafer with ethanol and distilled water for 10 minutes in order to remove various impurities (grease and dirt) attached to the surface of the substrate, and dry it naturally for use.

[0031] (2) Preparation of solution:

[0032] Mix the deionized aqueous solution of sulfonated polyaniline with a concentration of 1 mg / mL and the deionized aqueous solution of polydimethyldiallylamine hydrochloride with a concentration of 1 mg / mL to prepare complex solution I, in which the sulfonated polyaniline The molar ratio of the monomer to polydimethyldipropylene amine hydrochloride is 1:1; polyacrylic acid is dissolved in deionized water to prepare solution II with a concentration of 1mg / mL; sodium dodecylsulfonate Dissolve in deionized water to prepare a solution with a concentration of 2mg / mL, and dissolve tetrahydroperfluorooctyltrimethylsilane in toluene to prepare a solution with a concentration of 5mg / mL;

[0033] (3...

Embodiment 2

[0039] (1) Treatment of the substrate:

[0040] Spray the aluminum sheet with ethanol and distilled water for 10 minutes in order to remove various impurities (grease and dirt) attached to the surface of the substrate, and dry it naturally for use.

[0041] (2) Preparation of solution:

[0042] Mix the sulfonated polyetheretherketone solution with a concentration of 2mg / mL and the solution of polypropyleneamine with a concentration of 4mg / mL to prepare a complex solution I, wherein the monomer molar ratio of sulfonated polyether ether ketone to polypropyleneamine is 1:10; Dissolve polymethacrylic acid in deionized water to prepare solution II with a concentration of 4mg / mL; dissolve lithium perfluorooctane sulfonate in deionized water to prepare a solution with a concentration of 3mg / mL, Dissolve tetrahydroperfluorodecyltrimethylsilane in toluene to prepare a solution with a concentration of 1 mg / mL;

[0043] (3) Preparation of porous coating:

[0044]Spray the solution I a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com