Method for continuously neutralizing and decontaminating sodium chromate alkali solution

A technology of sodium chromate and alkaline solution, which is applied in the direction of chromate/dichromate, etc., can solve the problems of poor filtration performance, failure to fundamentally solve the problems of aluminum slime belt damage, poor filtration performance of aluminum slime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

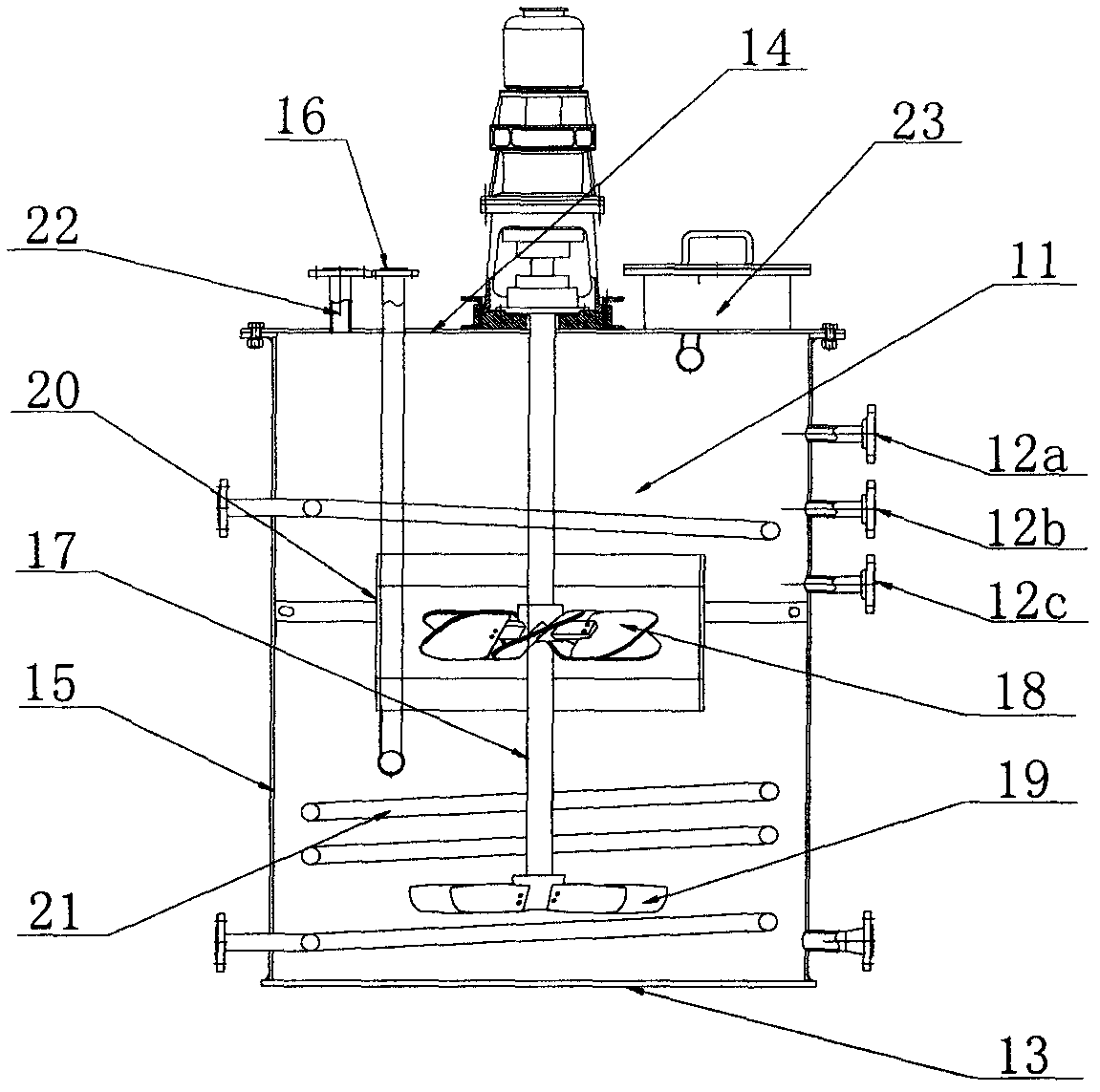

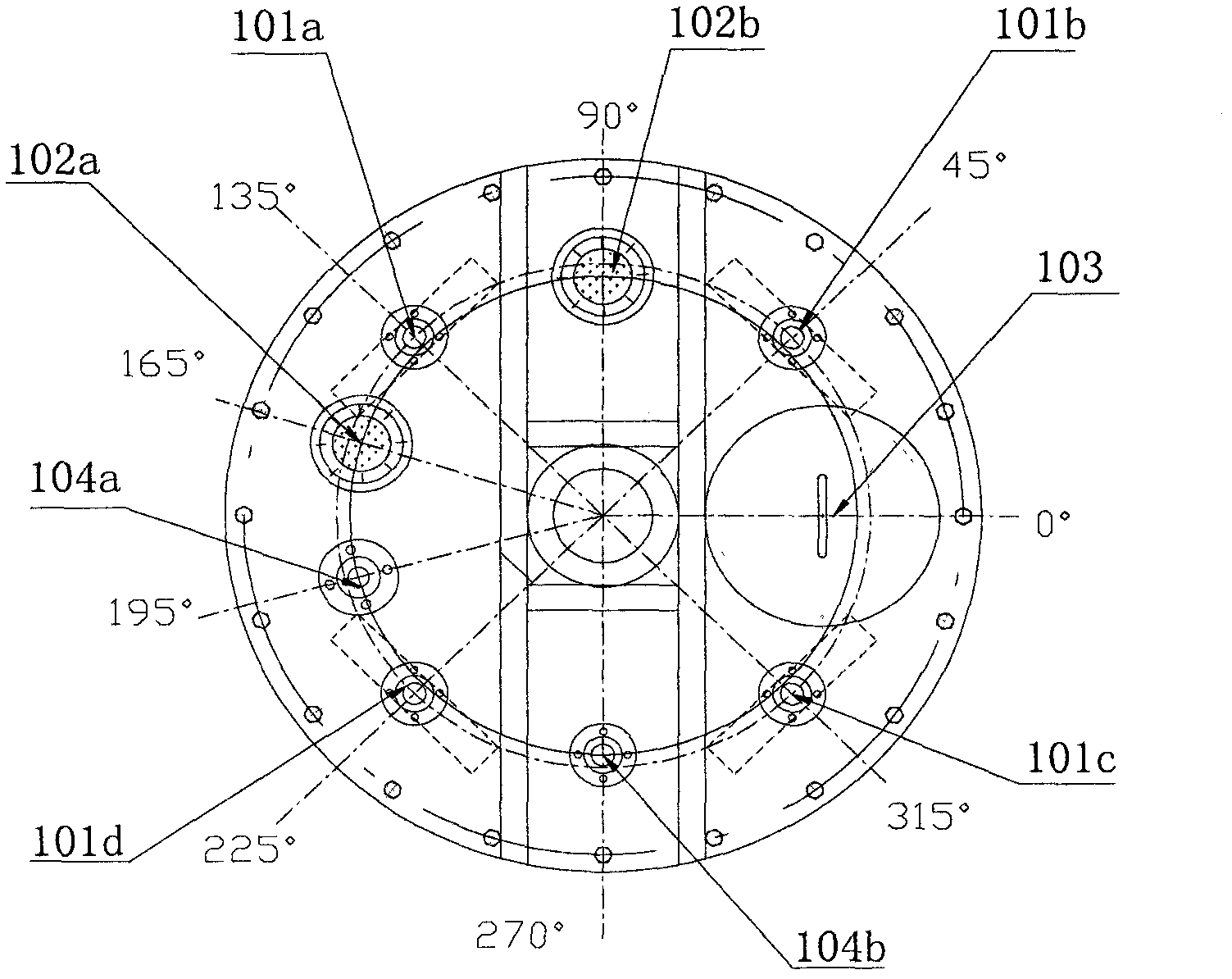

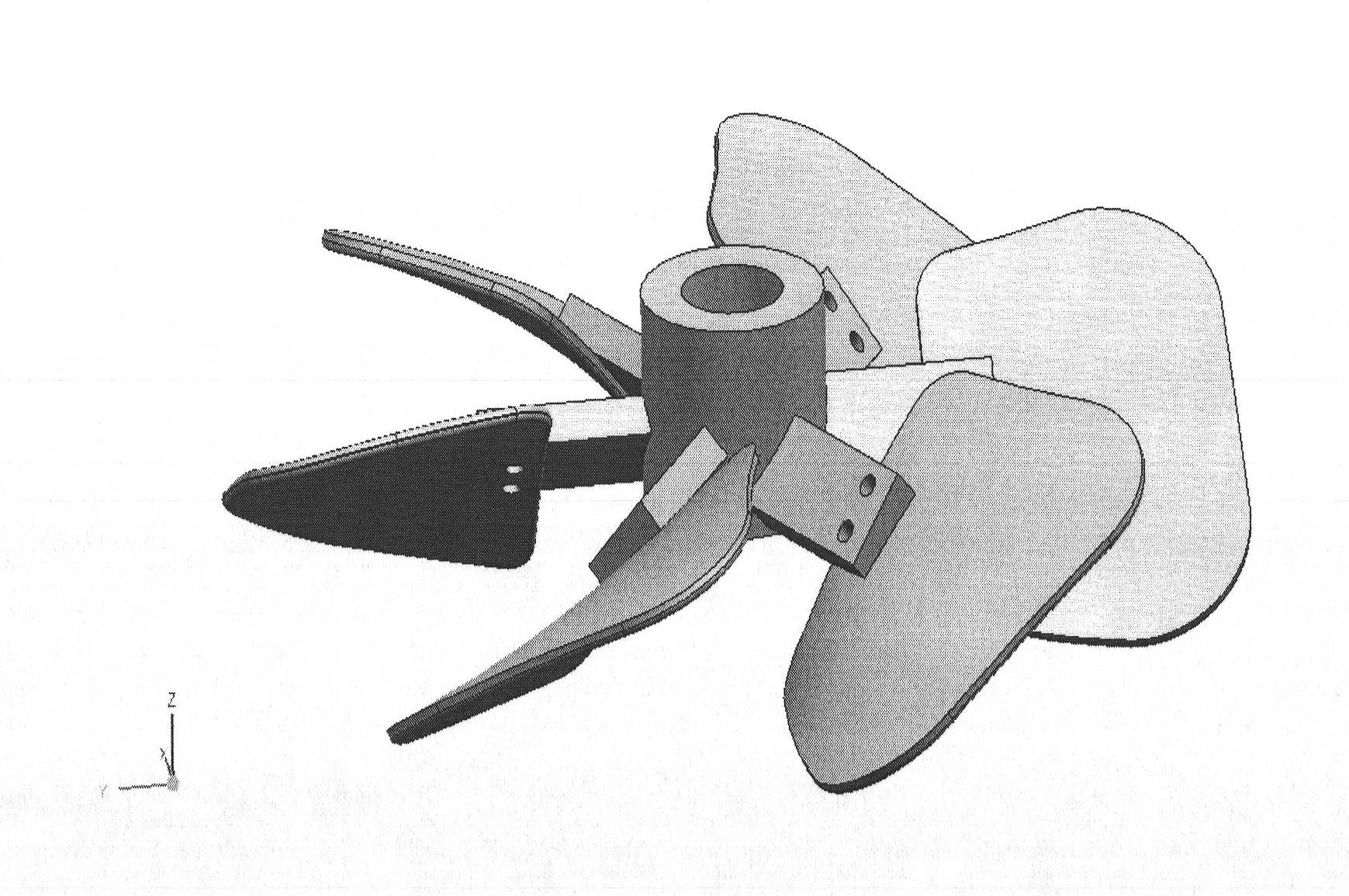

Method used

Image

Examples

Embodiment 1

[0085] ① Add Na to 20L 2 Cr 2 o 7 2H 2 O meter concentration is 295g L -1 Add 700g of industrial aluminum hydroxide as the crystal seed in the sodium chromate neutral liquid, make bottom material;

[0086] ②Put the base material into the neutralization reactor through the feed port of the neutralization reactor, and heat to keep the temperature of the base material at 120°C;

[0087] ③ will be Na 2 Cr 2 o 7 2H 2 O meter concentration is 287g L -1 and with Na 2 CO 3 The total alkalinity of the meter is 75g·L -1 The sodium chromate alkaline liquid obtained by roasting chromite ore to produce sodium chromate and the carbon dioxide gas mixture (the gas mixture is obtained by mixing carbon dioxide into the air) with a gas concentration of 18% by volume are separately and continuously added to the medium containing the base material and in the reactor, control the addition rate of the two, so that the pH value of the feed liquid in the neutralization reactor is 9.6 and t...

Embodiment 2

[0090] ①Add Na to 2L 2 Cr 2 o 7 2H 2 O meter concentration is 285g L -1 Add 65g of industrial aluminum hydroxide as crystal seed in the sodium chromate neutral liquid, make bottom material;

[0091] ②Put the base material into the neutralization reactor through the feed port of the neutralization reactor, and heat to keep the temperature of the base material at 100°C;

[0092] ③ will be Na 2 Cr 2 o 7 2H 2 O meter concentration is 315g L -1 and with Na 2 CO 3 The total alkalinity of the meter is 60g·L -1 The sodium chromate alkaline solution obtained by roasting chromite ore to produce sodium chromate and its concentration is expressed as Na 2 Cr 2 o 7 2H 2 O is calculated as 320g·L -1 And the acid value is H 2 SO 4 Calculated as 82g·L -1 The pre-acidification liquid is separately and continuously added to the neutralization reactor containing the bottom material, and the addition rate of the two feed liquids is controlled so that the pH value of the feed liq...

Embodiment 3

[0095] ①Add Na to 15L 2 Cr 2 o 7 2H 2 O meter concentration is 462g L -1 Add 280g according to the aluminum mud that embodiment 1 prepares and dry in the sodium chromate neutral liquid as crystal seed, make bottom material;

[0096] ②Put the base material into the neutralization reactor through the feed port of the neutralization reactor, and heat to keep the temperature of the base material at 95°C;

[0097] ③ will be Na 2 Cr 2 o 7 2H 2 O meter concentration is 368g L -1 and with Na 2 CO 3 The total alkalinity of the meter is 88g·L -1 The sodium chromate alkaline solution obtained by roasting chromite ore to produce sodium chromate and the concentrated sulfuric acid are separately and continuously added to the neutralization reactor containing the bottom material, and the addition rate of the two kinds of material liquids is controlled so that the neutralization reactor The pH value of the feed liquid is 8.8 and the level of the feed liquid amount is basically equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com