Energy-saving fireproof insulation board and manufacturing method thereof

A technology of fireproof insulation board and mixture, which is applied in the direction of heat preservation, fire protection, building components, etc. It can solve the problems that materials cannot meet the requirements of fire protection and heat preservation at the same time, and the market demand for building materials is large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

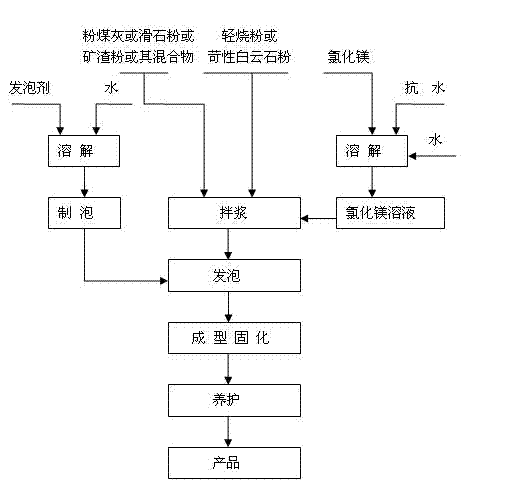

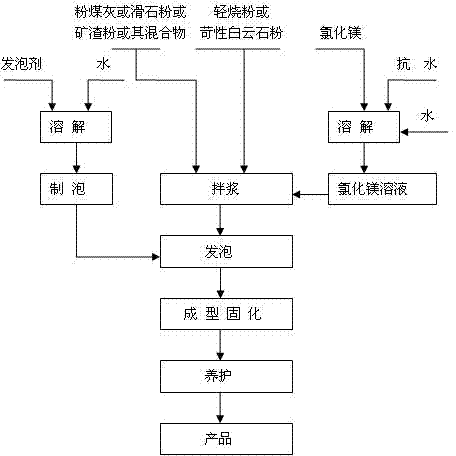

Method used

Image

Examples

Embodiment 1

[0005] Embodiment 1: Take by weighing 100kg of lightly burned powder, 12kg of magnesium chloride, 5kg of fly ash, 44kg of water, 0.05kg of foaming agent, and 0.1kg of water-resistant agent, wherein the foaming agent is a carbon chain length of 6 to 16 alkyl sulfates It is a mixture of animal protein glue with a mass ratio of 1.00:0.10, and the water-resistant agent is a mixture of ethyl silicate and sodium hexametaphosphate with a mass ratio of 1.00:0.10; the production method is to mix magnesium chloride, water-resistant agent at room temperature Dissolve in water in proportion to form a magnesium chloride solution. The magnesium chloride solution is mixed with lightly burned powder and fly ash to make a magnesium cement slurry. After the foaming agent is dissolved in water, it is made into a foam by a high-pressure air foaming machine. The magnesium cement slurry Fully mix with the foam, inject the mixture obtained in the foaming process into a special mold at room temperatur...

Embodiment 2

[0006] Embodiment 2: take by weighing caustic dolomite powder 100kg, magnesium chloride 40kg, talcum powder 30kg, water 120kg, foaming agent 0.5kg, anti-water agent 2kg, wherein foaming agent is that carbon chain length is 6~16 alkyl sulfate and animal A mixture of protein glue with a mass ratio of 1.00:1.00, and a water-repellent agent is a mixture of ethyl silicate and sodium hexametaphosphate with a mass ratio of 1.00:1.00; the production method is to mix magnesium chloride and water-resistant agent in proportion Dissolve in water to form a magnesium chloride solution, and mix and stir the magnesium chloride solution with lightly burned powder or caustic dolomite powder and talcum powder in proportion to make a magnesium cement slurry, dissolve the foaming agent in water and use a high-pressure air foaming machine to make foam, and the magnesium The cement slurry is fully mixed with the foam, and the mixture obtained in the foaming process is injected into the board machine ...

Embodiment 3

[0007] Embodiment 3: take by weighing the mixture 15kg of caustic dolomite powder 100kg, magnesium chloride 30kg, fly ash, talcum powder, slag powder, water 100kg, foaming agent 0.3kg, water-resistant agent 1kg, wherein foaming agent is that the carbon chain length is A mixture of 6-16 alkyl sulfates and animal protein glue in a mass ratio of 1.00:0.5, and a water-resistant agent is a mixture of ethyl silicate and sodium hexametaphosphate in a mass ratio of 1.00:0.5; the production method is at room temperature Dissolve magnesium chloride and anti-water agent in water in proportion to form a magnesium chloride solution, mix and stir the magnesium chloride solution with lightly burned powder or caustic dolomite powder and talcum powder in proportion to make magnesium cement slurry, dissolve the foaming agent in water and pass through high pressure Air foaming machine to make foam, fully mix the magnesium cement slurry and foam, pour the mixture obtained in the foaming process in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com