Waste heat recovery system for improving efficiency of electric dust collector

A waste heat recovery system and electrostatic precipitator technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problems of equipment and chimney corrosion, large energy consumption, etc. The effect of reducing coal consumption and volume for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing of specification sheet and embodiment:

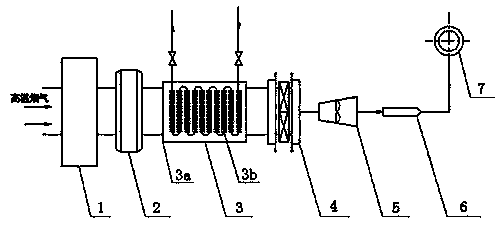

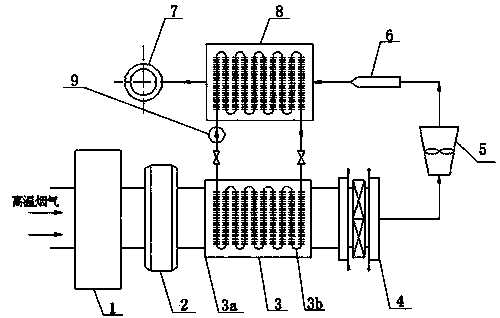

[0025] Such as figure 1 As shown, a waste heat recovery system for improving the efficiency of an electrostatic precipitator includes a boiler economizer 1, an air preheater 2, an electric precipitator 4, a desulfurization system 6, and a chimney 7 connected in sequence. The air preheater 2 Cooperate with the electrostatic precipitator 4 to install a waste heat recovery device I3, the waste heat recovery device I3 includes a shell 3a and a heat exchange tube bundle 3b cooperatingly arranged in the shell 3a, and the heat exchange tube bundle 3b is a spiral fin One end of the sheet tube is set as the liquid inlet I, and the other end is set as the liquid outlet I. The liquid entering the heat exchange tube bundle 3b of the present invention is the condensed water of the power plant, and it can also be other similar liquids. The heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com