Magnetic-control liquid crystal material, preparation method of liquid crystal display device and display device

A liquid crystal material and liquid crystal display technology, applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of complicated process, long post-processing time, and increased manufacturing cost of magnetically controlled liquid crystal materials, so as to reduce manufacturing costs and shorten The effect of postprocessing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

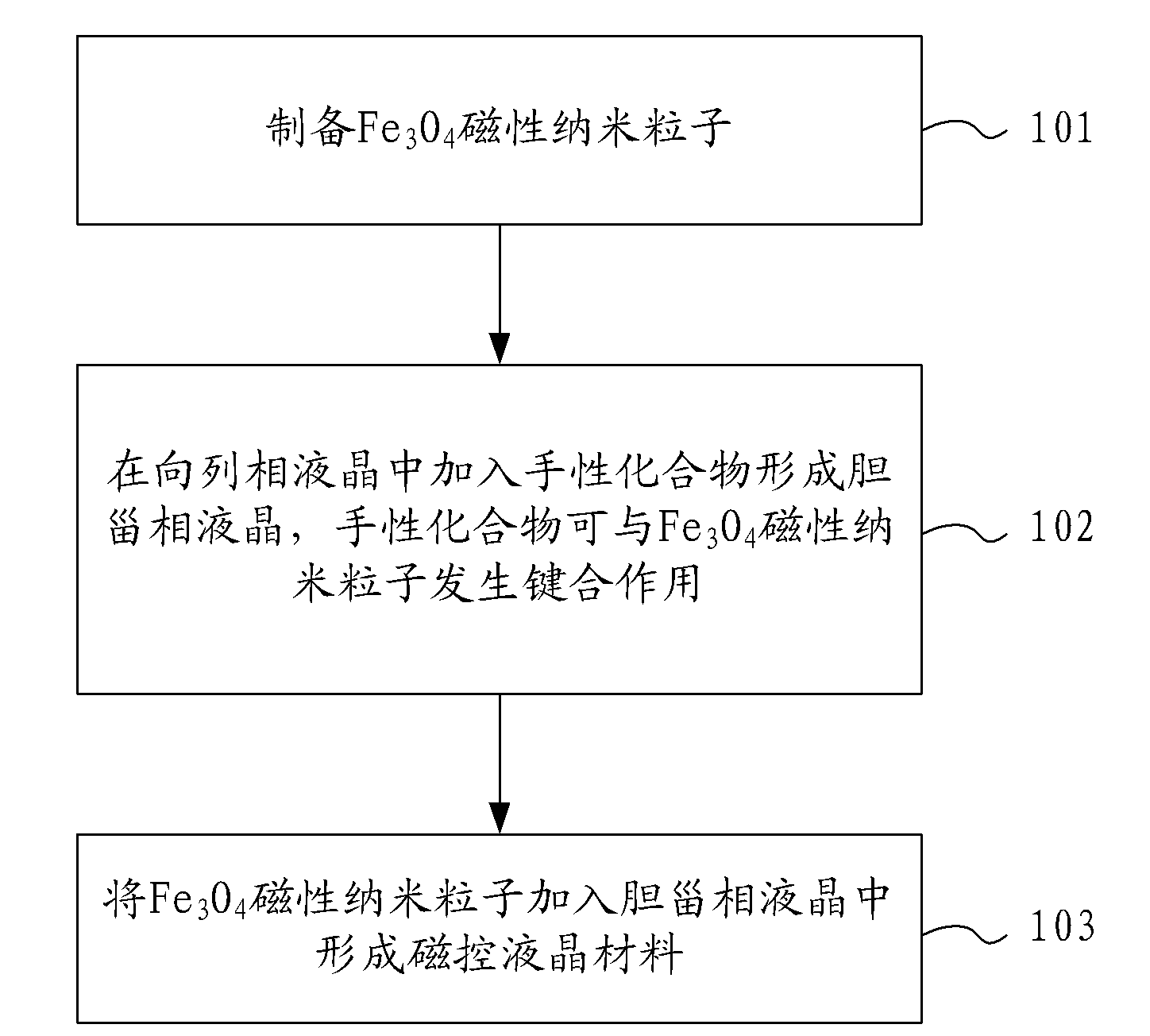

[0020] An embodiment of the present invention provides a method for preparing a magnetron liquid crystal material, comprising: preparing Fe 3 o 4 Magnetic nanoparticles; adding a chiral compound in the nematic liquid crystal to form a cholesteric liquid crystal, the chiral compound can be combined with the Fe 3 o 4 The magnetic nanoparticles are bonded; the Fe 3 o 4 Magnetic nanoparticles are added into the cholesteric liquid crystal to form the magnetron liquid crystal material.

[0021] An embodiment of the present invention also provides a method for preparing a liquid crystal display device, comprising: preparing an upper substrate with a first alignment layer; preparing a lower substrate with a second alignment layer; and aligning the first alignment layer of the upper substrate to The second alignment layer of the lower substrate, and combining the upper substrate and the lower substrate to form a plane-oriented liquid crystal cell; filling the magnetron liquid cryst...

Embodiment 1

[0026] Embodiments of the present invention provide a method for preparing a magnetron liquid crystal material, such as figure 1 As shown, the method includes the following steps.

[0027] 101. Preparation of Fe 3 o 4 magnetic nanoparticles.

[0028] Specifically, Fe 3 o 4 Magnetic nanoparticles can be prepared by chemical co-deposition method, microemulsion method or other methods known to those skilled in the art.

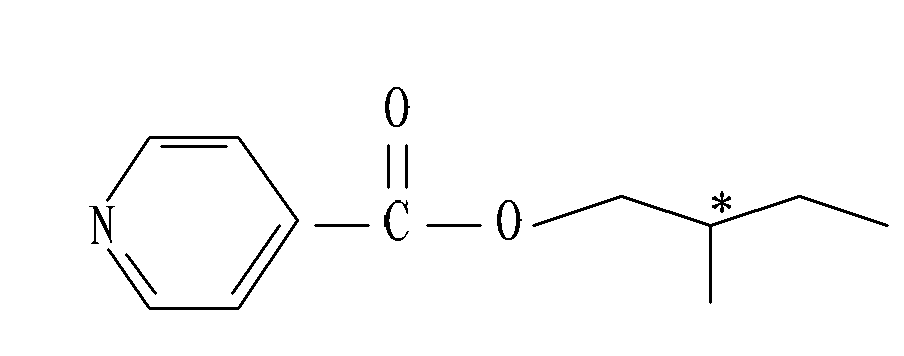

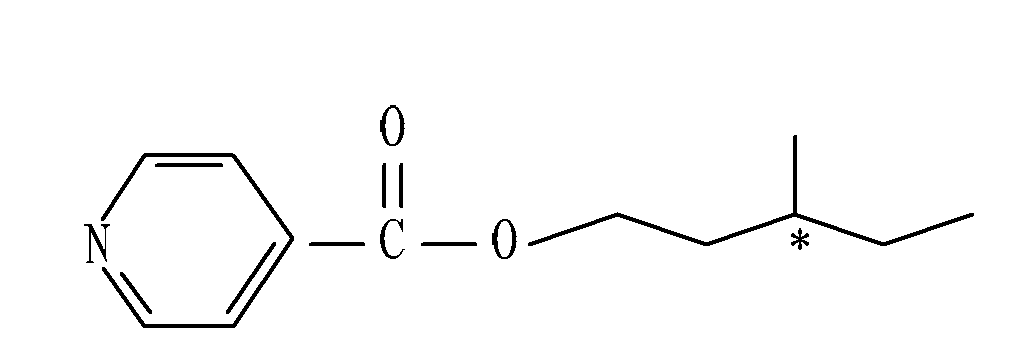

[0029] 102. Adding a chiral compound to the nematic liquid crystal to form a cholesteric liquid crystal, the chiral compound can be combined with the Fe 3 o 4 The magnetic nanoparticles are bonded.

[0030] 103, the Fe 3 o 4 Magnetic nanoparticles are added into the cholesteric liquid crystal to form the magnetron liquid crystal material.

[0031] Specifically, compared with the prior art, in this embodiment, when the cholesteric liquid crystal is formed, the nematic liquid crystal is added with Fe 3 o 4 Magnetic nanoparticles bond with chiral compounds...

Embodiment 2

[0038] This embodiment provides a method for preparing a liquid crystal display device. The initial reflected light color of the liquid crystal display device is green, and the liquid crystal display device has the magnetron liquid crystal material described in embodiment 1.

[0039] Step 1. Prepare a liquid crystal cell. This step includes: using 3% polyvinyl alcohol aqueous solution, coating one side of the glass substrate by the method of spin coating, baking at 80 ℃ for 30 minutes, and then rubbing and aligning in one direction with flannelette to form an orientation layer; After the glass substrates were aligned along the orientation direction, they were bonded with a polyethylene gasket with a thickness of 100 μm to form a plane-oriented liquid crystal cell.

[0040] Step 2, prepare Fe by chemical co-deposition 3 o 4 magnetic nanoparticles. This step includes: 10mL of 0.2mol / L FeCl 3 (ferric chloride) solution was slowly added to 10mL of 0.15mol / L FeCl 2 4H 2 O (fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com