Jeans elastic fabric and method for producing same

A technology of elastic fabrics and denim, applied in the field of textile fabrics, can solve the problems of poor fabric elasticity and moisture absorption and quick-drying performance, fading of pure cotton denim cotton, poor wearing comfort, etc., to achieve diversified hand feeling, improved water absorption, The effect of large adjustable range of feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

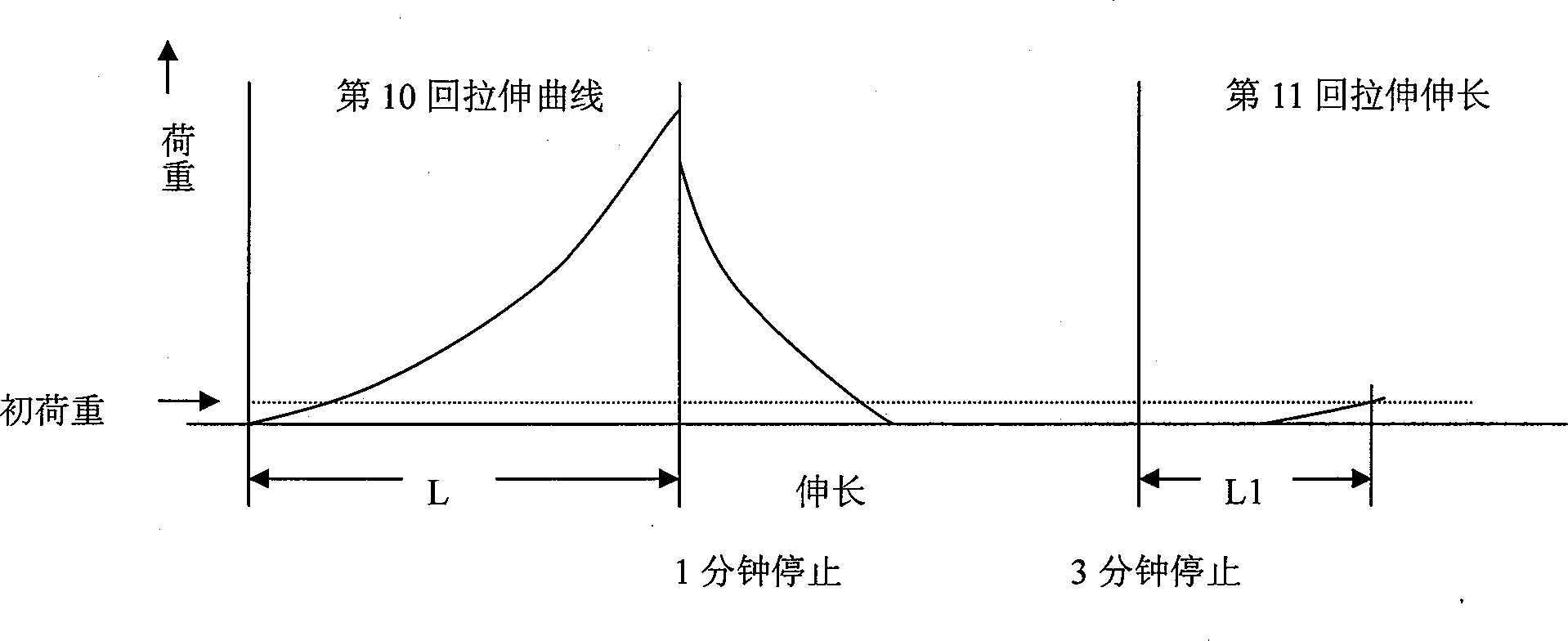

Method used

Image

Examples

Embodiment 1

[0054] A moisture-absorbing and quick-drying elastic denim fabric, the warp yarn is made of cationic dyeable thick and thin yarn (denier 110D), the weft yarn is made of 75D-24F-PBT / PET bicomponent yarn, the weave is broken twill, and the warp and weft density of the gray fabric is 133 pieces / inch×87 root / inch.

[0055] Pre-finishing: refining → drying

[0056] Alkali reduction processing and finishing conditions are:

[0057] The alkali reduction treatment is carried out in the continuous reduction machine, the temperature is 95°C, the volume fraction of industrial caustic soda is 25%, the residence time is 10min, the cloth speed is 60m / min, and the actual reduction rate is 11.7%.

[0058] Intermediate finishing conditions: Air wrinkle processing

[0059] Dyeing processing and finishing conditions are:

[0060]A liquid flow dyeing machine was used, and the dye was dyed with cationic black dye. The heating rate was 1°C / min, the maximum temperature was 120°C, the maximum tem...

Embodiment 2

[0064] A hygroscopic quick-drying elastic denim fabric, the warp is made of cationic dyeable coarse and detailed yarn (150D fineness) and 150D-144F-normal PET DTY are arranged in a ratio of 1:1, and the weft is made of 100D-36F-large glossy PET DTY and 75D -36F-Double-ply PBT yarn is arranged in 1:1, and the organization is DOBBY. Weaving on Tsudakoma water jet dobby, weaving tension 3500N, number of revolutions 400RPM, grey fabric warp and weft density: 123 / inch×114 / inch.

[0065] The above grey cloth passes:

[0066] Pre-finishing: scouring → pre-drying → intermediate setting

[0067] Alkali reduction processing and finishing conditions are:

[0068] Alkali reduction treatment was carried out in a liquid flow dyeing machine. The amount of caustic soda was 15g / L, the heating rate was 2°C / min, the maximum temperature was 110°C, the maximum temperature holding time was 30min, the cooling rate was 2.25°C / min, and the bath ratio was 1:25. The actual The alkali reduction rate i...

Embodiment 3

[0074] A moisture-absorbing quick-drying elastic denim fabric, the warp yarns are all made of cationic dyeable thick and thin yarns (150D fineness), and the weft yarns are made of cationic dyeable thick and thin yarns (150D fineness) and 75D-36F-PBT yarns in a ratio of 1:1 Arranged, organized as DOBBY. Weaving on Tsudakoma water jet dobby, weaving tension 3500N, number of revolutions 450RPM, grey fabric warp and weft density: 128 / inch×108 / inch.

[0075] The above grey cloth passed

[0076] Pre-finishing: scouring→pre-drying→intermediate styling

[0077] The alkali reduction treatment was carried out in a liquid flow dyeing machine. The industrial caustic soda dosage was 20g / L, the heating rate was 2°C / min, the maximum temperature was 110°C, the maximum temperature holding time was 30min, the cooling rate was 2.25°C / min, and the bath ratio was 1:20. The actual alkali reduction rate is 15.2%.

[0078] The dyeing and finishing conditions are:

[0079] Using a liquid flow dyei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear load | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com