Nitrile rubber and preparation method thereof

A technology of nitrile butadiene rubber and vinyl nitrile, which is applied in the field of high stability nitrile butadiene rubber and its preparation, can solve the problems of troublesome operation and unfavorable large-scale production, and achieve the effects of fast polymerization rate, improved stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

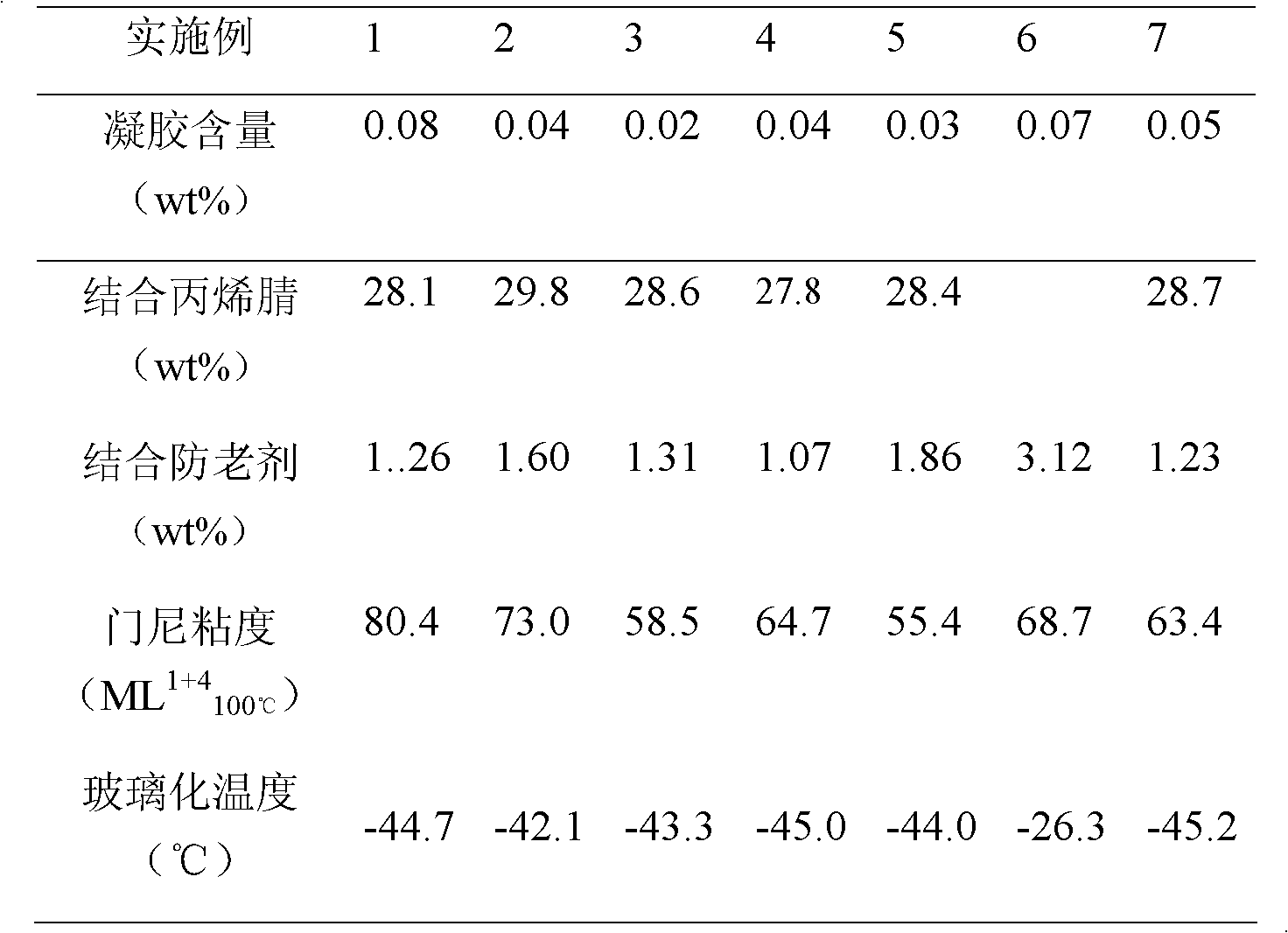

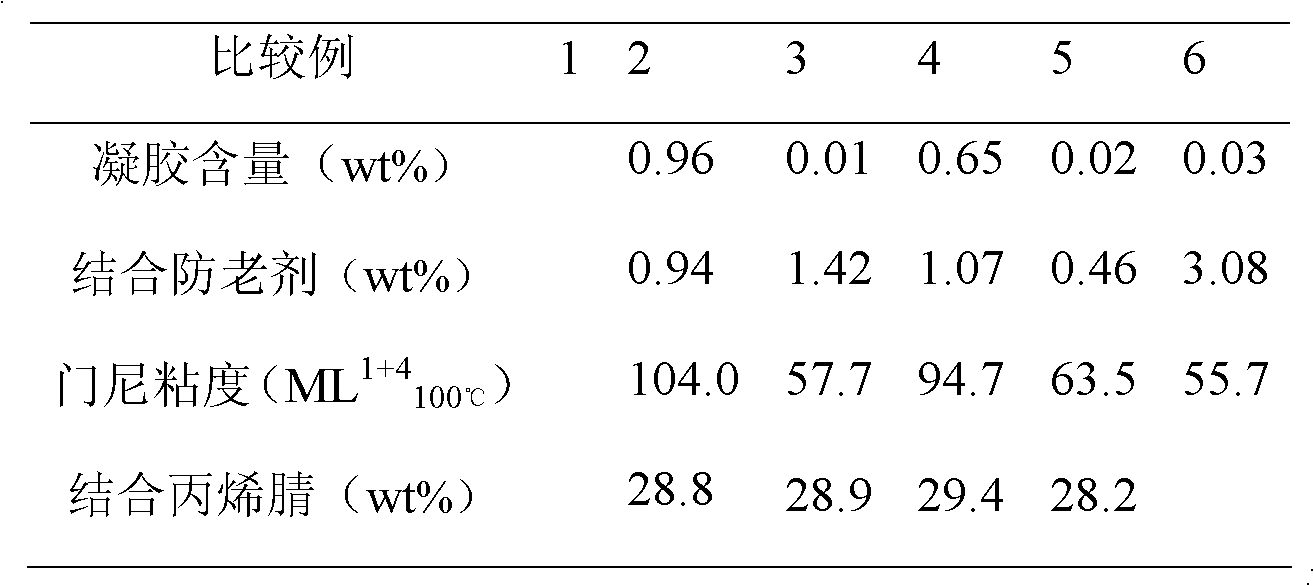

Examples

Embodiment 1

[0046] In the reactor, add water 175wt%, disproportionated potassium abietate 4.75wt%, β-naphthalenesulfonate sodium formaldehyde condensate 0.5wt%, potassium chloride 0.25wt%, EDTA 0.015wt%, ferrous sulfate 0.015wt%, Diabolite block 0.06wt%, tert-dodecyl mercaptan 0.275wt%, N-(p-anilinophenyl) methacrylamide 2.0wt%, acrylonitrile 27.0wt%; vacuum 25min, add 0.03wt% Then add 70.5wt% butadiene, stir and cool down to 5°C, add 0.06wt% initiator dicumyl peroxide, and polymerize at 5-8°C;

[0047] When the reaction was carried out for 6.0 hours, the measured conversion rate was 33.6%, and 25% of water was continuously added, disproportionated rosinate potassium 0.95wt%, β-naphthalenesulfonate sodium formaldehyde condensate 0.015wt%, potassium chloride 0.05wt%, EDTA. .005wt% mixed solution for 2.5 hours; when the conversion rate was 38.1%, 0.075wt% of tert-dodecylmercaptan was added continuously, and the mixture of acrylonitrile 0.5wt% was added for 2 hours;

[0048] When the reacti...

Embodiment 2

[0051] In the reactor, add water 175wt%, disproportionated potassium rosinate 4.50wt%, β-naphthalene sulfonate sodium formaldehyde condensate 0.3wt%, potassium chloride 0.25wt%, EDTA 0.025wt%, EDTA (FeNa) 0.015wt% , Diabolite block 0.10wt%, tert-dodecyl mercaptan 0.32wt%, N-(p-anilinophenyl) methacrylamide 2.5wt%, acrylonitrile 28.5wt%; vacuumize 25min, add 0.03wt % oxygen scavenger solution, then add 68.5wt% butadiene, stir and cool down to 5°C, add initiator dicumyl peroxide 0.06wt%, and polymerize at 5-8°C;

[0052] When the reaction was carried out for 5.0 hours, the measured conversion rate was 35.8%, continuously adding water 25%, disproportionated abietate potassium 0.9wt%, β-naphthalenesulfonate sodium formaldehyde condensate 0.1wt%, potassium chloride 0.05wt%, EDTA. .006wt% mixed solution for 2.0 hours; when the conversion rate was 41.5%, add 0.08wt% tertiary-dodecyl mercaptan and the mixture of acrylonitrile 0.5wt% in one go;

[0053] When the reaction was carried o...

Embodiment 3

[0055] In the reactor, add water 175wt%, disproportionated potassium abietate 4.75wt%, β-naphthalene sulfonate sodium formaldehyde condensate 0.375wt%, potassium chloride 0.30wt%, EDTA 0.025wt%, EDTA (FeNa) 0.010wt% , Diaobai block 0.15wt%, tert-dodecyl mercaptan 0.40wt%, N-(p-anilinophenyl) methacrylamide 2.0wt%, acrylonitrile 27.0wt%; vacuumize 30min, add 0.03wt % oxygen scavenger solution, then added 70.5wt% butadiene, stirred and cooled to 5°C, added 0.10wt% initiator dicumyl peroxide, and polymerized at 5-8°C;

[0056] When the reaction was carried out for 5.0 hours, the measured conversion rate was 36.4%, and water 25% was added at one time, disproportionated potassium abietate 0.85wt%, β-naphthalenesulfonate sodium formaldehyde condensate 0.125wt%, potassium chloride 0.06wt%, EDTA 0.005wt% mixed solution; when the conversion rate is 43.1%, add tertiary-dodecylmercaptan 0.10wt% and acrylonitrile 0.5wt% mixture in one go;

[0057] When the reaction was carried out for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com