Die attach film

A technology for attaching and chipping, applied in the direction of film/sheet adhesive, epoxy resin glue, adhesive type, etc., can solve the problems of reduced embedding of semiconductor substrates, reduced reliability of semiconductor packaging, etc., and achieves excellent Effects of expansion and pickup characteristics, prevention of burrs or flying chips, and improvement of embedability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0093] Preparation Example 1: Preparation of high molecular weight resin with low elasticity

[0094] 100 parts by weight of butyl acrylate, 100 parts by weight of ethyl acrylate, 70 parts by weight of acrylonitrile, 8 parts by weight of glycidyl methacrylate, 4 parts by weight of acrylic acid and 750 parts by weight of deionized distilled water were added to In a four-port 3L reactor with a stirrer, nitrogen replacement device and thermometer. Then, 2 parts by weight of suspending agent (polyvinyl alcohol (trademark: NH-17, produced by Nippon Ghosei) diluted with water to 4%) and 0.3 parts by weight of molecular weight regulator (dodecyl mercaptan) were added, To make a mixture. The resulting mixture was subjected to a nitrogen replacement process for about 1 hour, and then heated to 55°C. When the temperature reaches the preset temperature, 2 parts by weight of bis(ethylhexyl) peroxydicarbonate (trademark: Trigonox EHP, produced by Akzo Nobel) diluted with ethyl acetate to a ...

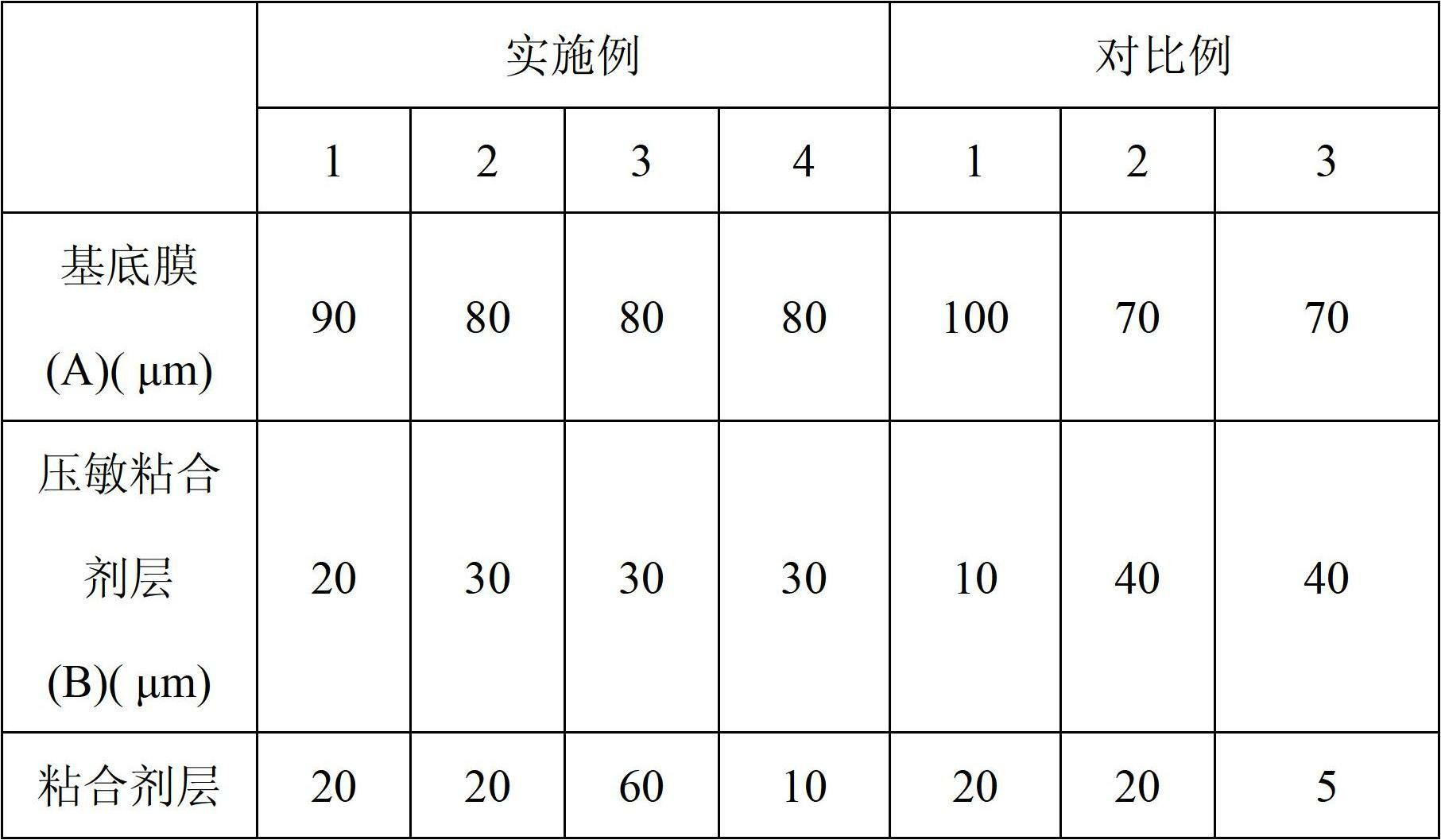

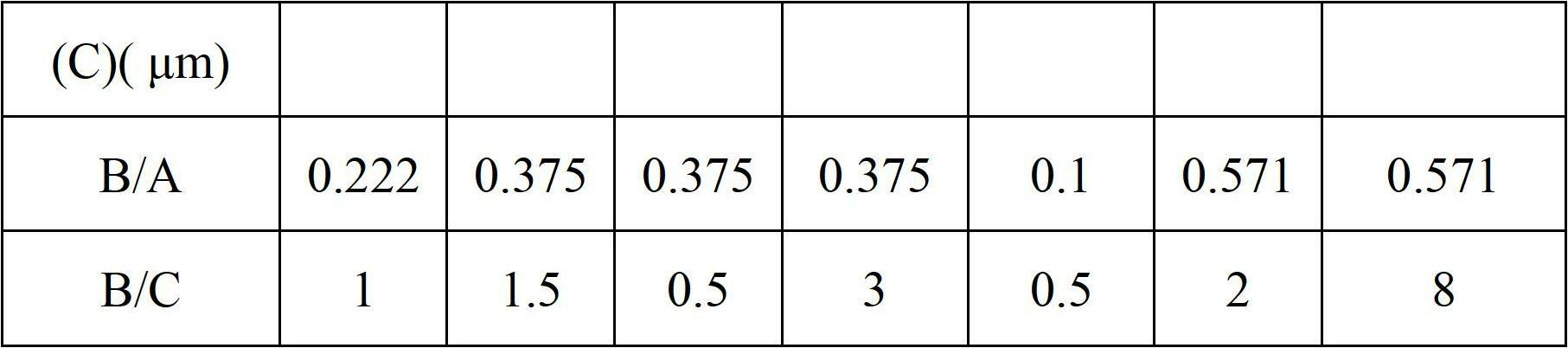

Embodiment 1

[0095] Example 1: Preparation of dicing film (pressure sensitive adhesive film)

[0096] With respect to 100 parts by weight of the multifunctional oligomer, 7 parts by weight of Darocur TPO as a photoinitiator and 100 parts by weight of acrylic copolymer, 5 parts by weight of isocyanate hardener and 10 parts by weight of isocyanate hardener are mixed with a weight average molecular weight of 20,000. A mixture of polyfunctional oligomers, to prepare a UV (ultraviolet light) curable pressure-sensitive adhesive composition, the acrylic copolymer is obtained by making 2-ethylhexyl acrylate, methyl acrylate and methacrylic acid It is made by copolymerization of methyl ester and has a weight average molecular weight of 800,000 and a glass transition temperature of 10°C. Then, the above-mentioned UV curable pressure-sensitive adhesive composition was coated on a polyester film that had been subjected to a release treatment and had a thickness of 38 μm so as to have a thickness of 20 μm...

Embodiment 2

[0100] The die attach film was produced in the same manner as in Example 1, except that the pressure-sensitive adhesive film was prepared by controlling the pressure-sensitive adhesive layer to have a thickness of 30 μm and using a polyolefin film having a thickness of 80 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com