Preparation method of highly-dispersed meso pore gamma-Al2O3 base alkali (soil) metal composite adsorbent

A technology of metal compounding and alkaline earth metals, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as complex processes and achieve the effects of simple processes, high concentration of aluminum sources, and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Highly dispersed mesoporous γ-Al 2 o 3 Preparation of base (earth) metal composite adsorbent

[0034]First use acid to decompose the aluminum source, then mix the obtained sol with the Pluronic triblock copolymer solution, and add the alkali metal precursor salt or alkaline earth metal precursor salt according to the molar ratio of alkali (earth) metal and aluminum ≤ 12% , to obtain a mixture of sol-Pluronic triblock copolymer-alkali metal precursor salt or alkaline earth metal precursor salt. (earth) metal composite adsorbent;

[0035] Alternatively, after the mixture is fully stirred and uniformly mixed, it is prepared by hydrothermally assisted solvent evaporation-induced self-assembly, that is, after the mixture is treated under hydrothermal conditions, it is then prepared by solvent evaporation-induced drying, vacuum drying and calcination. The alkaline (earth) metal composite adsorbent.

[0036] In the process of using acid to decompose the aluminum...

Embodiment 2

[0044] Example 2: Preparation of Mg-functionalized mesoporous γ-Al with F127 as template 2 o 3 base composite adsorbent

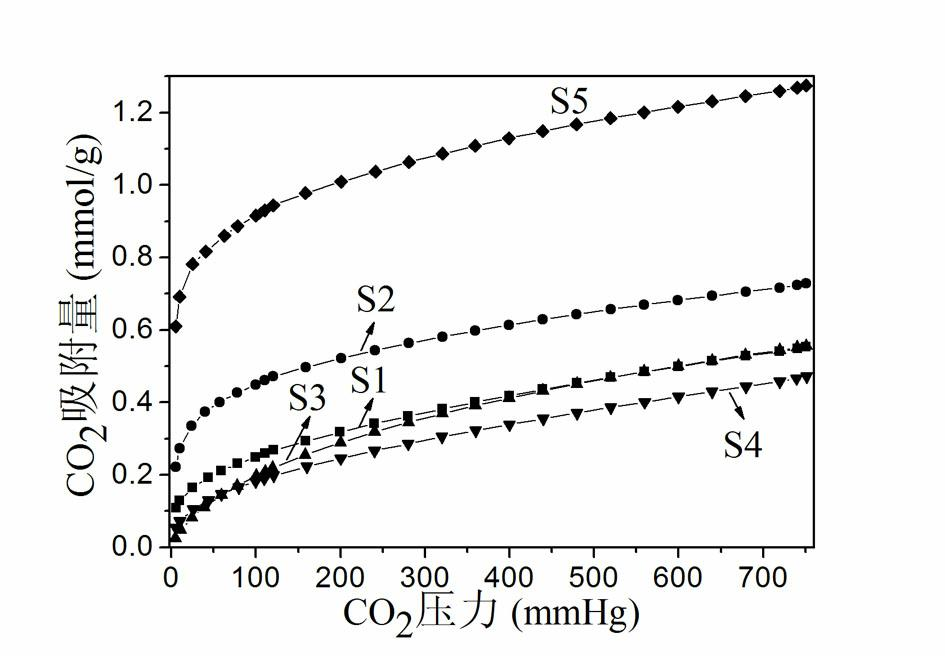

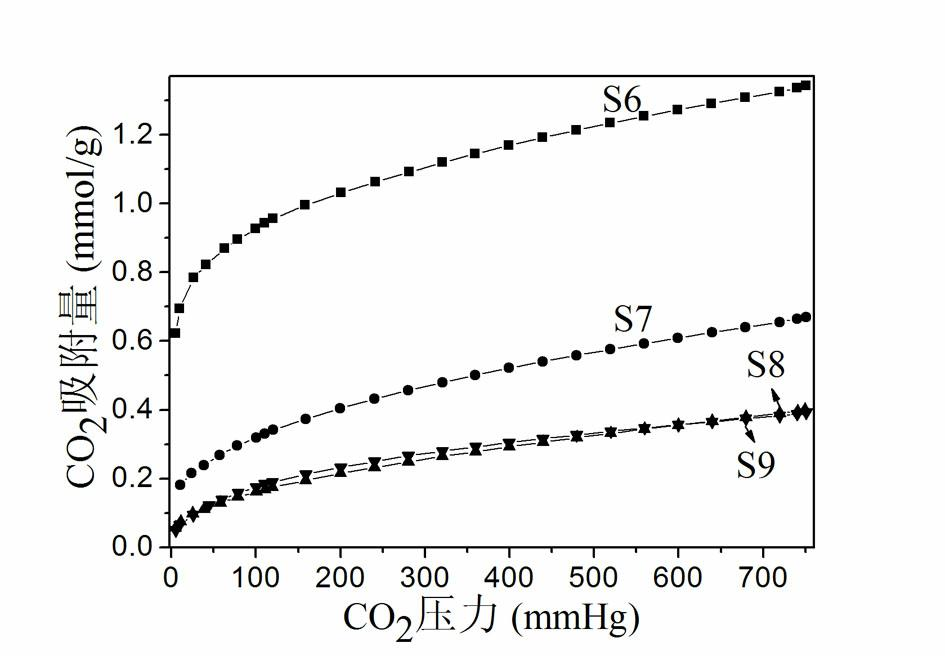

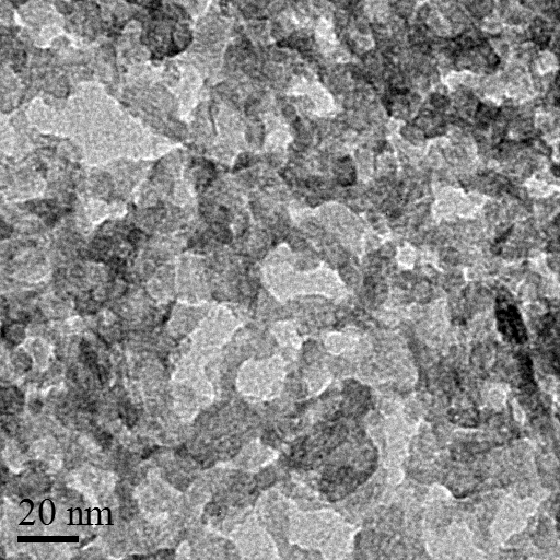

[0045] Dissolve 3.0 g of F127 in 40 ml of 95% ethanol, stir well at room temperature for 2 h to obtain a colorless and transparent solution A; add 3.0 g of SB powder (a kind of high-purity thin aluminum water produced in Germany) to 40 ml of distilled water Stone) and 0.53 ml, 14.5 M mol / L nitric acid solution, stirred thoroughly for 1 h to obtain Sol B. Solution A and sol B were mixed at room temperature, and Mg(NO 3 ) 2 ·6H 2 O, after fully stirring for 4 h, the mixture was subjected to solvent evaporation induction drying at 60 °C for 48 h, vacuum drying at 80 °C for 24 h, and static calcination at 600 °C for 4 h to obtain Mg-functionalized mesoporous γ- al 2 o 3 matrix composite material with a specific surface area of 197.1 m 2 / g, the pore volume is 1.03 cm 3 / g, and the average pore diameter is 20.9 nm. CO at room temperature 2 The adsor...

Embodiment 3

[0046] Example 3: Preparation of Ca-functionalized mesoporous γ-Al with F127 as template 2 o 3 base composite adsorbent

[0047] Dissolve 3.0 g of F127 in 40 ml of 95% ethanol, stir well at room temperature for 2 h to obtain a colorless and transparent solution A; add 3.0 g of SB powder and 0.33 ml of 14.5 mol / L nitric acid solution to 40 ml of distilled water in sequence , fully stirred for 1 h to obtain Sol B. Solution A and sol B were mixed at room temperature, and Ca(NO 3 ) 2 4H 2 O, after fully stirring for 4 h, the mixture was subjected to solvent evaporation induction drying at 80 °C for 24 h, vacuum drying at 120 °C for 12 h, and static calcination at 400 °C for 4 h to obtain Ca-functionalized mesoporous γ- Al 2 o 3 matrix composite material with a specific surface area of 159.6 m 2 / g, the pore volume is 0.73 cm 3 / g, and the average pore diameter is 18.4 nm. CO at room temperature 2 The adsorption capacity is 0.73 mmol / g (see figure 1 middle curve S-2)....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com