Method for preparation of ZnO/diatomite nanoscale composite material by layer-by-layer self-assembly

A nano-composite material and layer-by-layer self-assembly technology, applied in the field of nano-composite material preparation, can solve the problems of high cost of wastewater treatment, difficult practical application, small powder particle size, etc., and achieve easy recovery, strong adsorption capacity, Simple effect of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

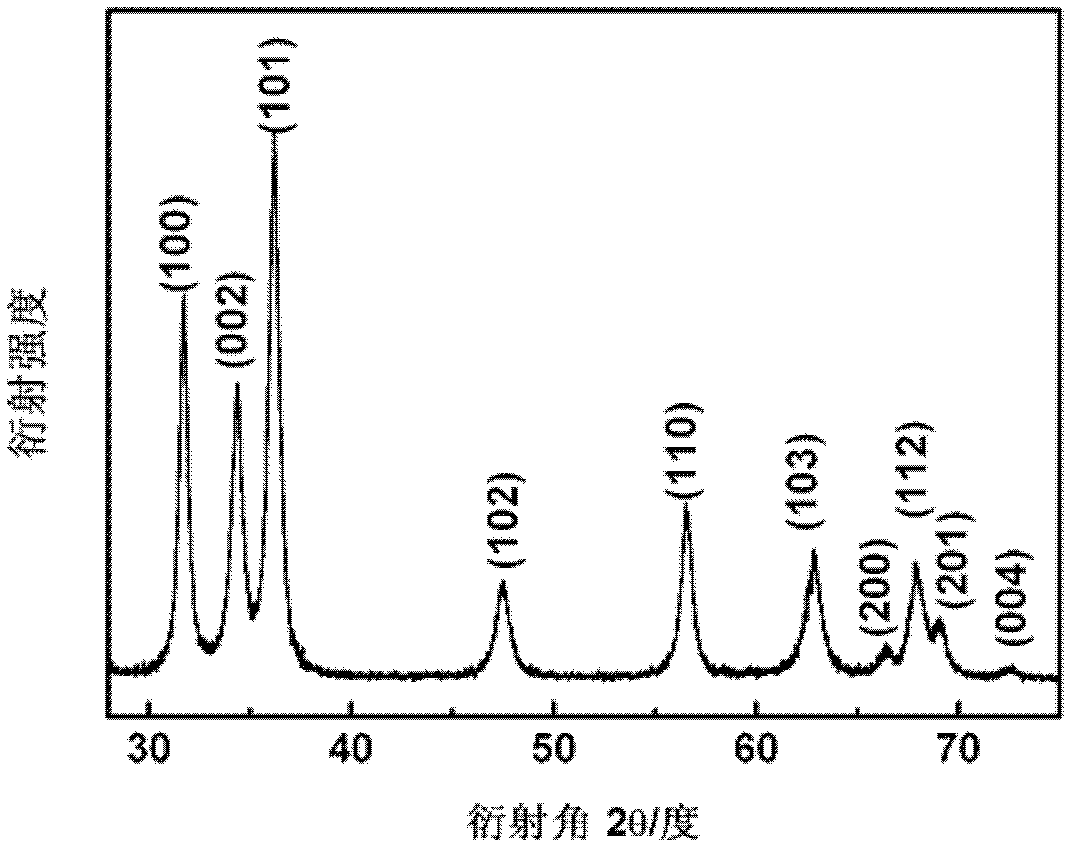

[0040]At room temperature, measure 150ml of absolute ethanol in a three-necked flask, add 2.82g of Zn(CH 3 COO) 2 2H 2 O, heated in a water bath to 80°C, and mechanically stirred until a transparent solution was obtained; at room temperature, weighed 1.6g of sodium hydroxide, dissolved in 100ml of absolute ethanol, and stirred magnetically to completely dissolve it. The obtained sodium hydroxide solution was slowly added dropwise into the zinc acetate solution under a water bath at 70°C. Stirring was continued for 30 min after the dropwise addition was completed. The resulting product was cooled to room temperature, and ultrasonically dispersed for 30 minutes to obtain a zinc oxide sol.

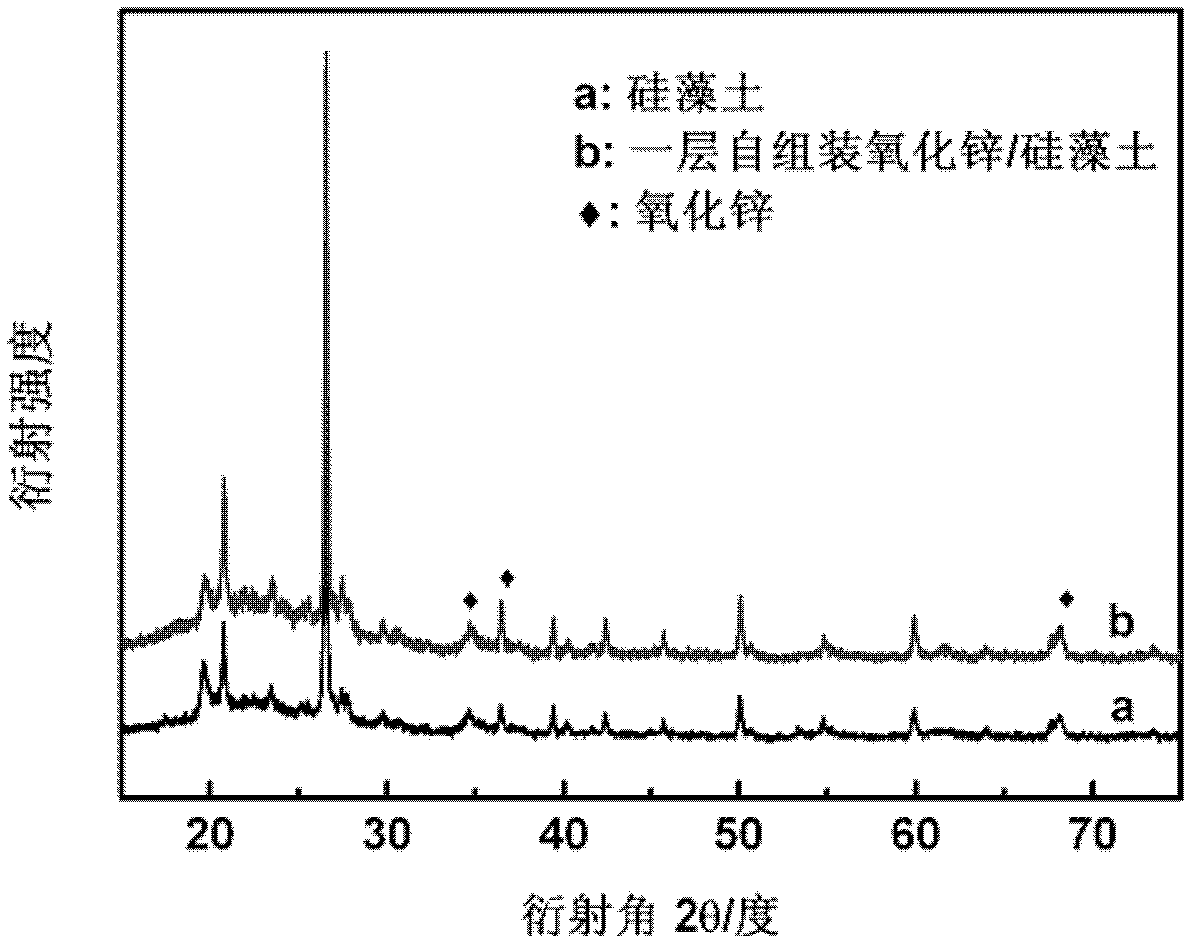

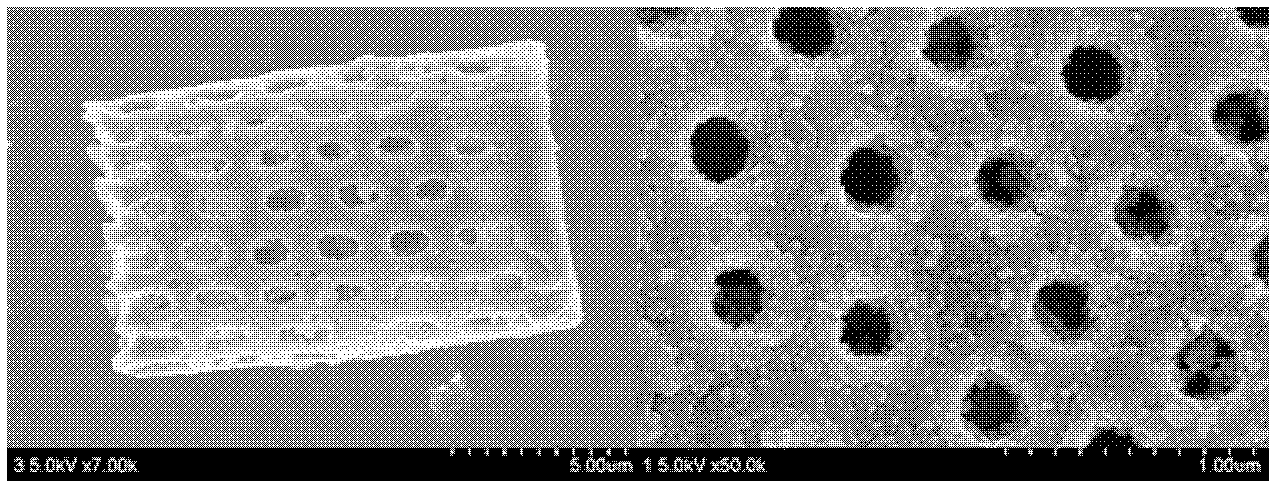

[0041] Weigh 3g of diatomaceous earth and immerse in 20ml of the obtained zinc oxide sol, stir for 2min, filter, wash the product 3 times with deionized water; then immerse the product in 20ml of polyacrylic acid aqueous solution with a concentration of 0.01mmol / L, stir for 2min, filter, r...

Embodiment 2

[0045] At room temperature, measure 150ml of absolute ethanol in a three-necked flask, add 2.82g of Zn(CH 3 COO) 2 2H 2 O, heated in a water bath to 80°C, and mechanically stirred until a transparent solution was obtained; at room temperature, weighed 1.6g of sodium hydroxide, dissolved in 100ml of absolute ethanol, and stirred magnetically to completely dissolve it. The obtained sodium hydroxide solution was slowly added dropwise into the zinc acetate solution under a water bath at 70°C. Stirring was continued for 30 min after the dropwise addition was completed. The resulting product was cooled to room temperature, and ultrasonically dispersed for 30 minutes to obtain a zinc oxide sol.

[0046] Weigh 3g of diatomaceous earth and immerse in 20ml of the obtained zinc oxide sol, stir for 2min, filter, wash the product 3 times with deionized water; then immerse the product in 20ml of polyacrylic acid aqueous solution with a concentration of 0.01mmol / L, stir for 2min, filter, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap