Ruthenium-based catalyst for preparing gamma-valerolactone from acetylpropionic acid, and preparation method for ruthenium-based catalyst

A ruthenium-based catalyst, levulinic acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low γ-valerolactone yield, Harsh reaction conditions, unfavorable catalyst recovery and other problems, achieve the effects of high selectivity and yield, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

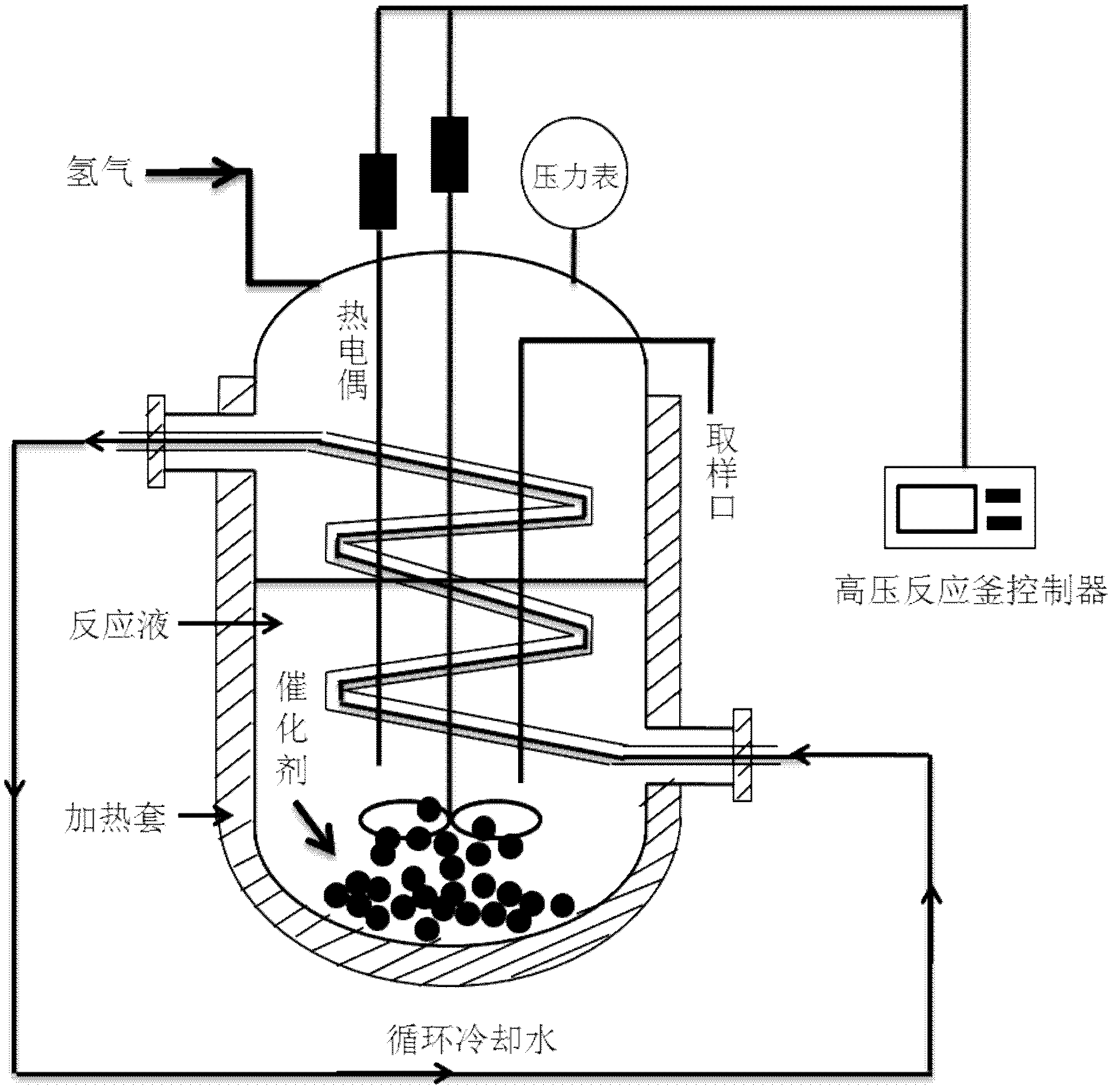

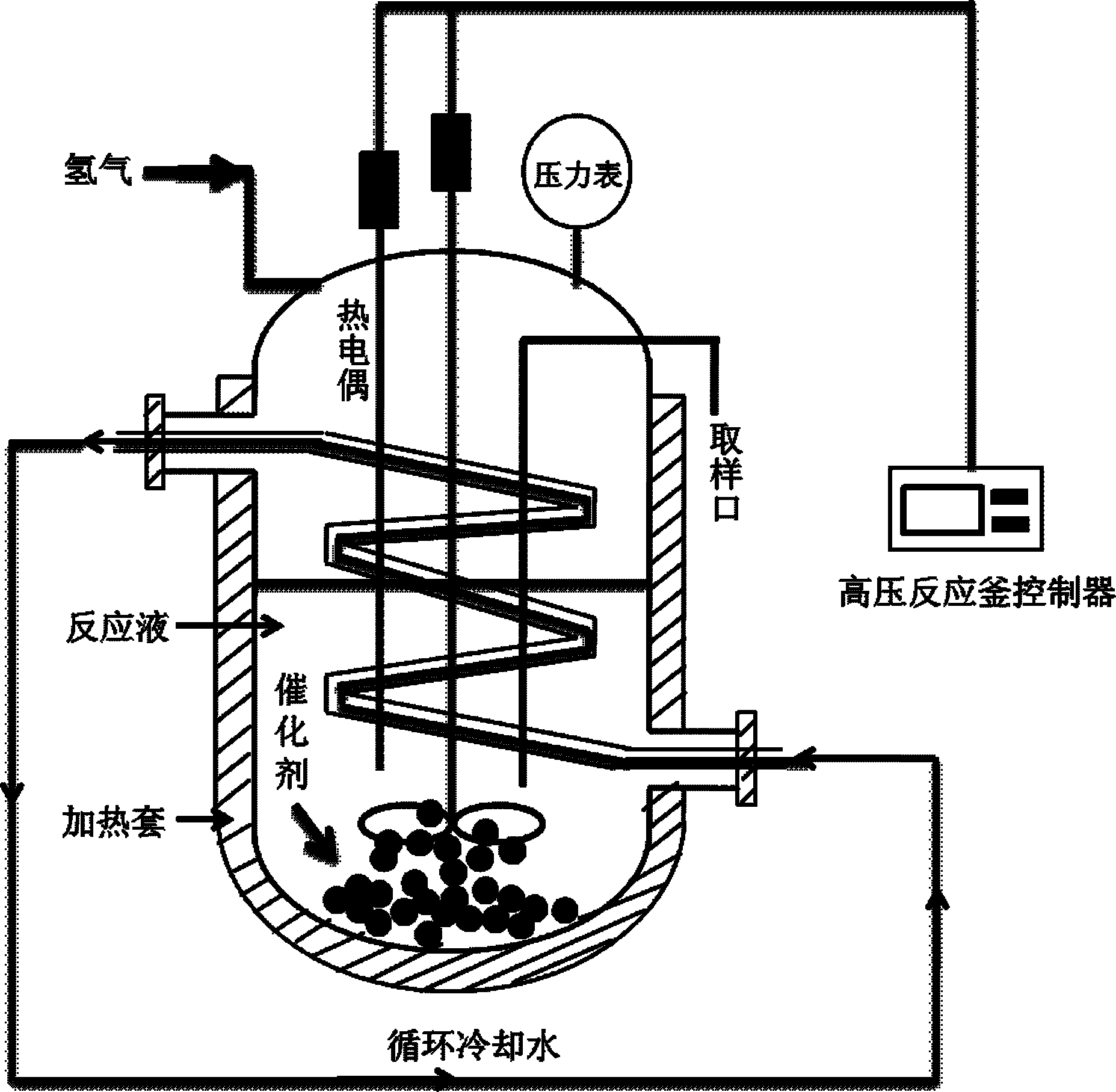

Image

Examples

Embodiment 1~4

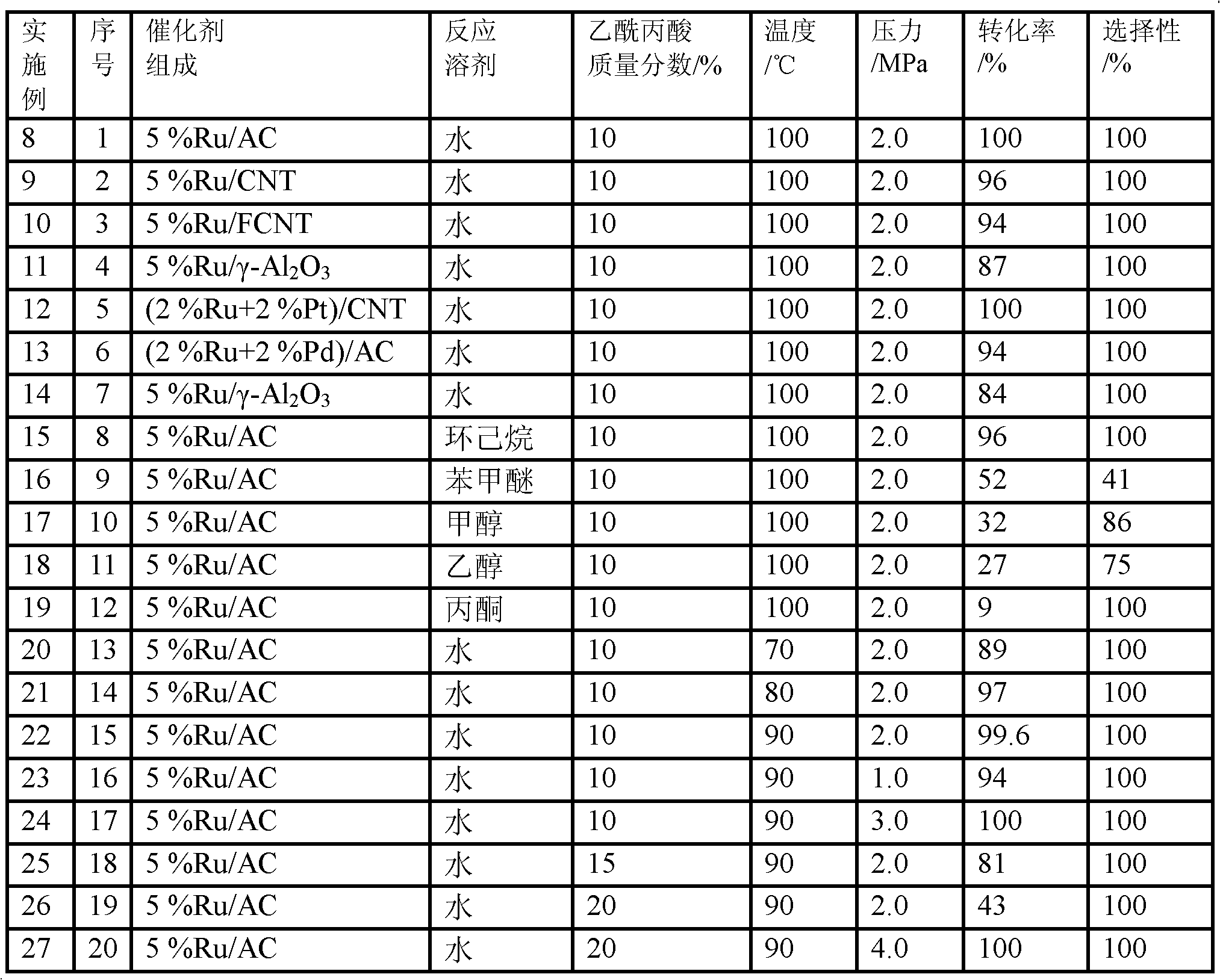

[0022] Embodiment 1~4: Catalyst preparation

[0023] Preparation of 5wt%Ru / AC, 5wt%Ru / CNT, 5wt%Ru / FCNT and 5wt%Ru / γ-Al by microwave-assisted pyrolysis 2 0 3 catalyst. Weigh 0.0105g (5wt%) triruthenium dodecacarbonyl and 0.1g carrier (coconut shell activated carbon, carbon nanotubes, carbon nanotubes after oxidation treatment), mix, grind in agate mortar and pestle for 20min and then load into fluidized reaction In the tube, purge with argon for 2h, heat with microwave 800W for 5min, the flow rate of argon in the reaction is: 50mL / min, cool to room temperature in argon atmosphere, about 12h, you can get the supported ruthenium-based catalyst, listed in Table 1 The serial numbers are 1~4.

Embodiment 5

[0024] Embodiment 5: catalyst preparation

[0025] Preparation of (2wt%Ru+2wt%Pt) / CNT catalysts by microwave-assisted pyrolysis. Weigh 0.0084g (2wt%) triruthenium dodecacarbonyl, 0.0081g (2wt%) platinum acetylacetonate and 0.2g untreated carbon nanotubes, mix them, grind them in an agate mortar for 20min, and put them into a fluidized reaction tube During the process, purging with hydrogen for 2 hours, heating with 800W microwave for 5 minutes, the flow rate of hydrogen in the reaction: 50mL / min, cooling to room temperature in an argon atmosphere, about 12 hours, you can get the supported ruthenium-platinum bimetallic catalyst, listed in the serial number in Table 1 for 5.

Embodiment 6

[0026] Embodiment 6: catalyst preparation

[0027] The (2wt%Ru+2wt%Pd) / AC catalyst was prepared by microwave-assisted pyrolysis. Take by weighing 0.0168g (2wt%) triruthenium dodecacarbonyl, 0.0229g (2wt%) palladium acetylacetonate and 0.4g coconut shell activated carbon, mix, put into the fluidized reaction tube after grinding 20min in the agate mortar, hydrogen Purging for 2 hours, heating with 800W microwave for 3 minutes, the hydrogen flow rate in the reaction: 50mL / min, cooling to room temperature in an argon atmosphere, about 12 hours, you can get the supported ruthenium-platinum bimetallic catalyst, which is listed in Table 1 as serial number 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com