Method for producing acetylacetone beryllium

A production method, the technology of acetylacetone, applied in the preparation of aldehyde/ketone chelate, organic chemistry, etc., can solve the problems of environmental pollution, complex process, beryllium toxicity, etc., reduce the difficulty of the process, reduce the number of process steps, and achieve high product purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

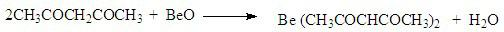

Method used

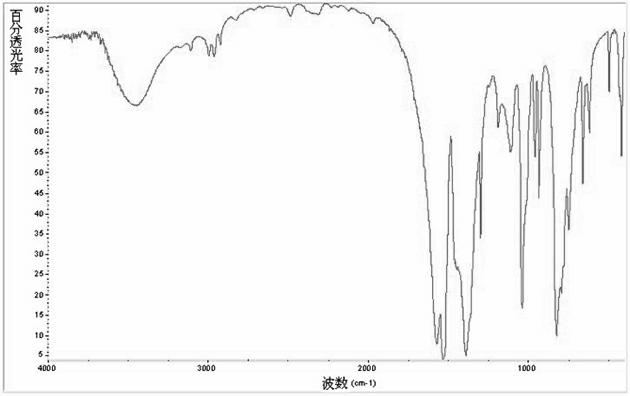

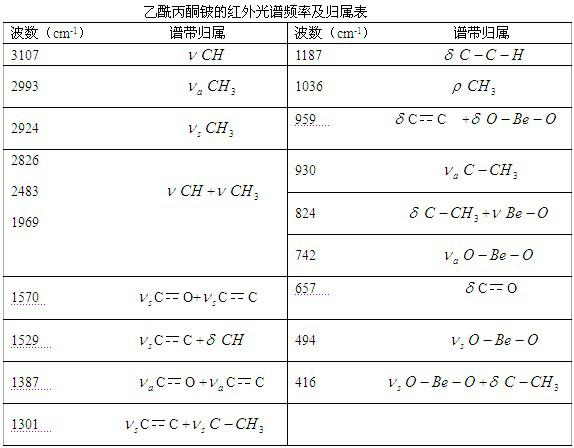

Image

Examples

Embodiment 1

[0020] Add 45kg of isopropanol into the reaction kettle as a solvent, raise the temperature to 50-60°C, add 2.4kg of beryllium oxide powder into the reaction kettle under stirring, so that the beryllium oxide powder is evenly dispersed in isopropanol, and then add dropwise 22kg of acetylacetone, the temperature is controlled at 50-60°C until the dropwise addition is completed, the temperature of the reactor is properly raised, and the reaction is kept at 60°C for 5 hours, filtered while it is hot to remove a small amount of insoluble matter, and the filtrate is cooled and then filtered. Air-dried or vacuum-dried to obtain 18.38 kg of colorless crystals, which is the product, with a yield of 92.5%.

Embodiment 2

[0022] Add 50kg of ethanol as a solvent into the reaction kettle, raise the temperature to 50-60°C, add 2.5kg of beryllium oxide powder into the reaction kettle under stirring, so that the beryllium oxide powder is evenly dispersed in the ethanol, and then dropwise add 20kg of acetylacetone , the temperature is controlled at 50-60°C until the dropwise addition is completed, the temperature of the reactor is properly raised, and the reaction is kept at 70°C for 3.5 hours, filtered while hot to remove a small amount of insoluble matter, the filtrate is cooled and then filtered, and the filter cake is dried in the air or vacuum After drying, 18.94 kg of colorless crystals were obtained, which was the product, and the yield was 91.5%.

Embodiment 3

[0024] Add 55kg of ethanol as a solvent into the reaction kettle, raise the temperature to 50-70°C, add 2.5kg of beryllium oxide powder into the reaction kettle under stirring, so that the beryllium oxide powder is evenly dispersed in the ethanol, and then dropwise add 24kg of acetylacetone , the temperature is controlled at 50-70°C, until the end of the dropwise addition, the temperature of the reactor is properly raised, and the reaction is kept at 75°C for 4 hours, filtered while it is hot, and a small amount of insoluble matter is removed, and the filtrate is cooled and then filtered, and the filter cake is dried in the air or vacuum After drying, 19.42 kg of colorless crystals were obtained, which was the product, and the yield was 93.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com