Preparation method of dehydroabietic acid

A technology of dehydroabietic acid and rosin, applied in the field of rosin disproportionation reaction, can solve the problems of increased equipment investment, large solvent loss, complicated operation, etc., and achieve the effects of less three wastes, convenient post-treatment, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] Catalyst preparation

[0025] (1) carrier preparation: ZrOCl 2 ·8H 2 Slowly add 322 g of O to 100 mL of deionized water with constant stirring. 85 ml of aqueous ammonia solution with a mass concentration of 25% was added dropwise to the formed solution to adjust the pH value to 10. Seal the formed hydroxide sol together with the mother liquor, cook at 95°C for 60 hours, filter the resulting precipitate, wash it with deionized water, and wash it with AgNO 3 Cl in it cannot be detected - exist. The filter cake was dried at 120°C for 8 hours and then calcined at 450°C for 2 hours to obtain ZrO 2 carrier with a specific surface area of 165m 2 / g, the pore volume is 0.25mL / g. Then, the prepared ZrO 262 grams and γ-Al 2 o 3 51 grams were mixed and extruded into rods, dried at 120°C for 24 hours, and then calcined at 600°C for 4 hours in a muffle furnace. The carrier specific surface area is 183m 2 / g, the pore volume is 0.47mL / g.

[0026] (2) Loading of the ac...

Embodiment 1

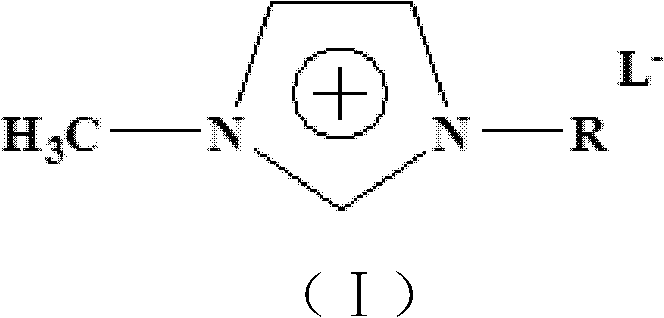

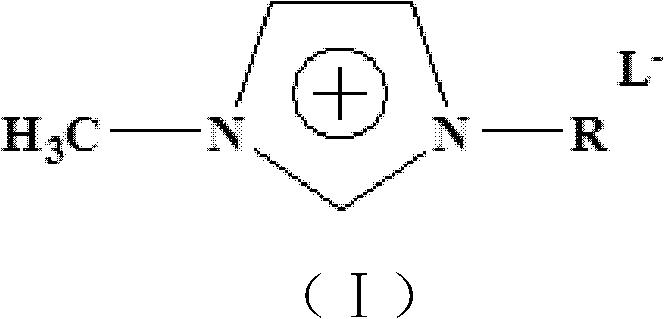

[0028] In a 250 ml three-necked bottle, add 31 grams of ground commercially available rosin, Pt / ZrO 2 -γ-Al 2 o 3 (the loading capacity of Pt is 1% by carrier mass) 6 grams of solid acid catalysts, 150 grams of 1-methyl-3-butylimidazolium tetrafluoroborate ionic liquid constitutes reaction system, connects reflux condenser, is heated to 110 ° C, reflux reaction for 5 hours, stop heating, after the reaction system is cooled to room temperature (20 ° C), add 100 mL of toluene to the reaction system for extraction, obtain the upper layer liquid and the lower layer precipitate, the lower layer precipitate is a solid acid catalyst and ionic liquid, Recycling and reuse, take the upper layer and carry out rotary concentration to remove toluene to obtain the crude product of disproportionated rosin (i.e. concentrate), the crude product is subjected to silica gel column chromatography (eluent is petroleum ether: ethyl acetate = 5: 1 (volume ratio)) , TLC follow-up detection (developi...

Embodiment 2

[0030] In a 250 ml three-necked bottle, add 31 grams of ground commercially available rosin, Pt / ZrO 2 -γ-Al 2 o 3 (the loading of Pt is 0.25% by carrier mass) 9 grams of solid acid catalyst, 300 grams of 1-methyl-3-octyl imidazolium bisulfate ionic liquid constitute reaction system, connect reflux condenser, be heated to 80 ℃ , reacted for 10 hours, after the reaction system was cooled to room temperature (20°C), 100 mL of toluene was added to the reaction system for extraction, and the upper layer and the lower layer were obtained. The lower layer was solid acid catalyst and ionic liquid, which were recycled and reused. The toluene was removed by rotary concentration to obtain the crude product of disproportionated rosin (i.e. concentrate), the crude product was subjected to silica gel column chromatography (eluent was petroleum ether: ethyl acetate=5:1 (volume ratio)), followed by TLC detection (developing solvent was Petroleum ether: ethyl acetate=5: 1 (volume ratio)), co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Carrier specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com