Production and application method of bamboo wood mould-proof dyeing agent

A production method and dyeing agent technology, applied in application, wood treatment, impregnation of wood, etc., can solve the problems of high production cost, poor safety, and toxicity of antifungal agents, and achieve cheap raw materials, convenient application, and natural color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

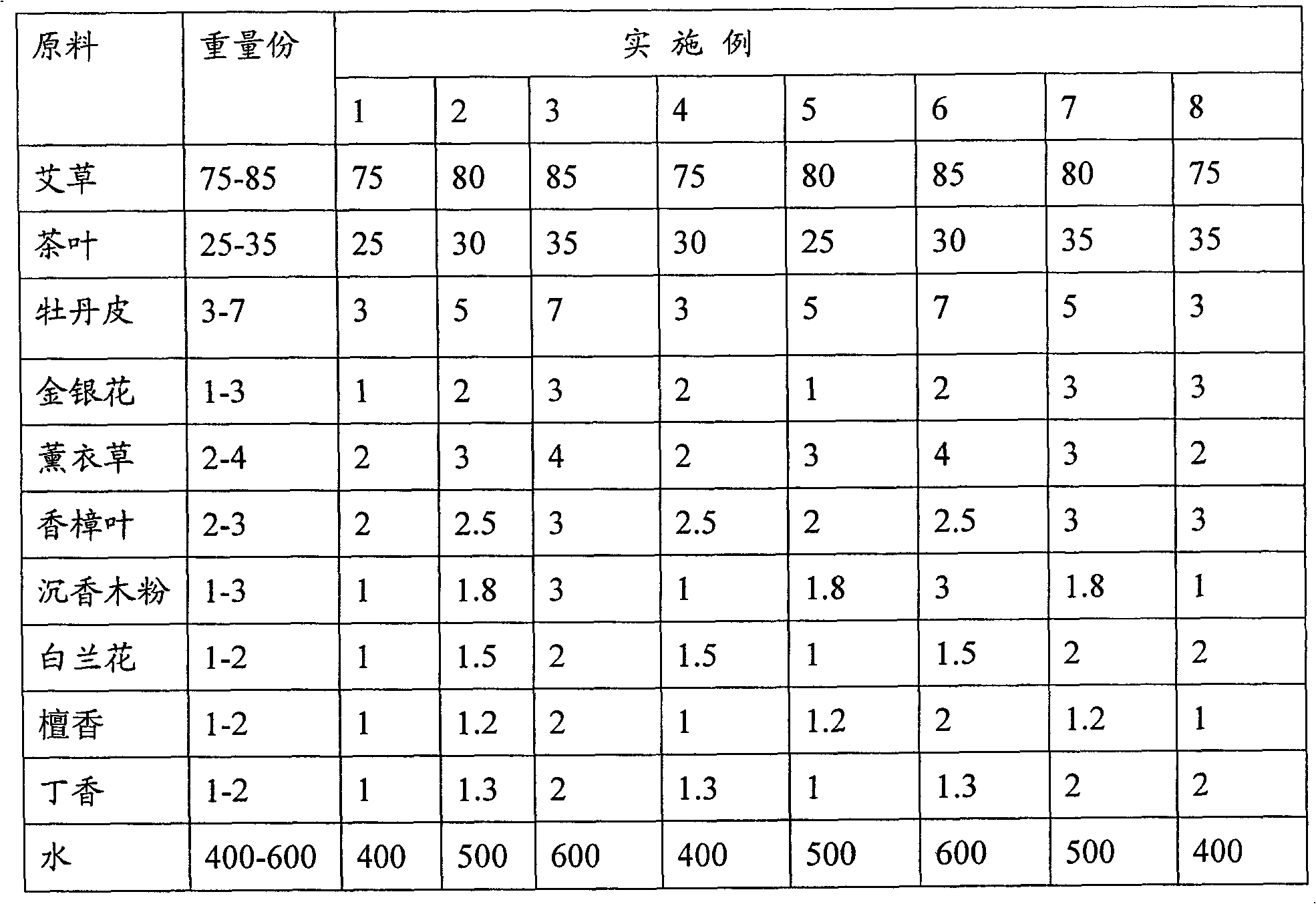

[0015] Embodiment 1 (corresponding raw material and weight ratio value of embodiment 1 in the comparison table 1):

[0016] Mix 75 parts of wormwood, 25 parts of tea leaves, 3 parts of peony bark, 1 part of honeysuckle, 2 parts of lavender, 2 parts of camphor leaves, 1 part of agarwood powder, 1 part of white orchid, 1 part of sandalwood, 1 part of clove and 400 Put industrial water into the reaction kettle together, cover and heat up to 50°C after stirring, keep warm for 2 hours, then raise the temperature to 100°C, keep warm for 5 hours, cool down to 45°C naturally, and the filtrate obtained by discharging and filtering is the anti-mold of bamboo wood Dye stock solution.

[0017] When applying, dilute it according to the weight ratio of stock solution: water = 1:100, pour it into the dipping tank with heating and heat preservation device, put it into the bamboo wood to be dipped until it is completely submerged, cover it and heat it to 50°C, keep it warm for 5 hours, and the...

Embodiment 2-8

[0018] All the other examples 2-8 are compared with the corresponding examples in the table and their proportions by weight, and are prepared in the same way as example 1 for standby or put into use.

[0019] Wherein preferred with embodiment 1-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com