Method for preparing active calcium powder by using teleostean chine

A technology of active calcium powder, fish spine, applied in application, food preparation, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

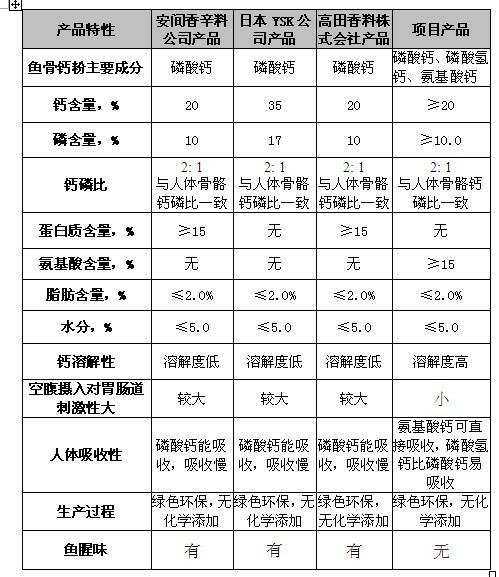

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] ① Wash the hard bone fish spine and put it in a reactive container, add lipase, add water and soak, adjust the pH to 7.4, and increase the temperature to 45 ° C to react;

[0025] ② Take out the fish spine, crushed into thick particles with a particle size at 2mm after drying, and then pierced with a specialty removal agent with a rough granules of the fish spine: the weight of the specialty removal = 1: 0.5 is evenly mixed with gauzePut it in the water for 1 hour, abandon the water, take the rough particles of the fish spine and the mixture of the special -made removal agent, sieve, remove the special -produced removal agent;

[0026] ③ Rinse the rough particles of the fish spine and dry it, crush it into particles with a particle size below 1mm, and then hydrolyze it with hybrid enzymes, filter it after hydrolysis, and leave the filtrate;

[0027] ④ Make the filter fluid into powder through the drying method of spraying, that is, active calcium powder;

[0028] The specia...

Embodiment 2

[0032] ① Wash the hard bone fish spine and put it in a reaction container, add lipase, add water and soak, adjust the pH to 7.5, and increase the temperature to 46 ° C to react;

[0033] ② Take out the fish spine, crushed into thick particles with a particle size at 3mm after drying, and then pierced with a specialty removal agent with a rough granules of the fish spine: the weight of the specialty removal = 1: 0.8 is evenly mixed with gauzePut it in the water for 1 hour, abandon the water, take the rough particles of the fish spine and the mixture of the special -made removal agent, sieve, remove the special -produced removal agent;

[0034] ③ Rinse the rough particles of the fish spine and dry it, crush it into particles with a particle size below 1mm, and then hydrolyze it with hybrid enzymes, filter it after hydrolysis, and leave the filtrate;

[0035] ④ Make the filter fluid into powder through the drying method of spraying, that is, active calcium powder;

[0036] The specia...

Embodiment 3

[0041] ① Wash the hard bone fish spine and put it in a reactive container, add lipase, add water and soak, adjust the pH to 7.6, and increase the temperature to 48 ° C to react;

[0042] ② Take out the fish spine, crushed into thick particles with a particle size at 3mm after drying, and then pierced with the special -made removal agent with the rough granules of the fish spine: the weight of the specialty removal = 1: 1 is evenly mixed with gauze and wrap it with gauze., Put in the water and boil for 1.5 hours, abandon the water, take the rough particles of the fish spine and the mixture of the special -made remover, sieve, remove the special -produced removal agent;

[0043] ③ Rinse the rough particles of the fish spine and dry it, crush it into particles with a particle size below 1mm, and then hydrolyze it with hybrid enzymes, filter it after hydrolysis, and leave the filtrate;

[0044] ④ Make the filter fluid into powder through the drying method of spraying, that is, active ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com