Easy-to-demould precoated sand and production process of easy-to-demould precoated sand

A technology of coated sand and easy demoulding, which is applied in the direction of manufacturing tools, metal processing equipment, casting molding equipment, etc., can solve the problems of high friction resistance between molds and sand cores, increase production costs, and reduce production efficiency, so as to improve production Effects of efficiency, friction reduction, high yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, the easy-release coated sand includes 100kg of raw sand, which is silica sand for foundry; the anti-mucosal liquid is selected asphalt-kerosene liquid, which is 0.1kg; 0.1kg flake graphite powder; 2.0kg thermoplastic phenolic resin; 2kg hexamethylenetetramine solution with a concentration of 15%; 0.1kg calcium stearate.

[0019] The production of the present invention is as follows: heat 100kg of raw sand to 150-160°C, put it into the started sand mixer, add 0.1kg of asphalt-kerosene liquid, mix for 10s, add 0.1kg of flake graphite powder and mix for 10s, add 2.0kg For thermoplastic phenolic resin, after mixing for 40s, blow in cold air for 15s, then add 2kg of hexamethylenetetramine solution (concentration: 15%) and mix for 10s, add 0.1kg of calcium stearate and mix for 15s, then blow in cold air for 30s for the second time, Finished products are made from sand.

Embodiment 2

[0021] The difference between the present embodiment and the first embodiment is that the anti-mucosal solution added in the present embodiment is a paraffin-kerosene solution with a mass of 0.3 kg, and the added flake graphite powder has a mass of 0.25 kg.

[0022] The production steps of the present invention are as follows: heat 100kg of raw sand to 150-160°C, put it into the started sand mixer, add 0.3kg of paraffin-kerosene solution, mix for 10s, add 0.25kg of flake graphite powder and mix for 10s, add 2.0 kg of thermoplastic phenolic resin, mixed for 40s, blown in cold air for 15s, then added 2kg of hexamethylenetetramine solution (concentration: 15%) mixed for 10s, added 0.1kg of calcium stearate, mixed for 15s, and blown in cold air for 30s for the second time , Sand out to make finished products.

Embodiment 3

[0024] The difference between this embodiment and embodiment one and embodiment two is: in the present embodiment, the anti-mucosal liquid that adds is coal tar-kerosene solution, and its quality is 0.2kg, and the flake graphite powder quality that adds is 0.15kg.

[0025] The production process of the present invention is as follows: heat 100kg of raw sand to 150-160°C, put it into the started sand mixer, add 0.2kg of coal tar-kerosene solution, mix for 10s, add 0.15kg of flake graphite powder and mix for 10s, add 2.0kg of thermoplastic phenolic resin, mixed for 40s, blown in cold air for 15s, then added 2kg of hexamethylenetetramine solution (concentration: 15%) mixed for 10s, added 0.1kg of calcium stearate, mixed for 15s, blown in cold air for 30s for the second time , Sand out to make finished products.

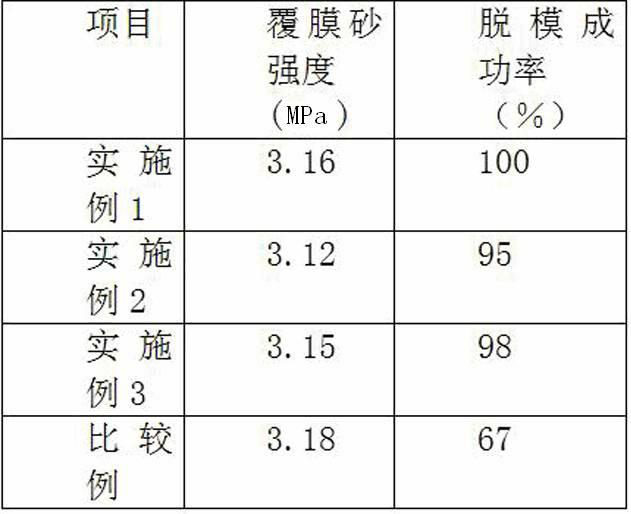

[0026] In order to better illustrate the technical effect that the present invention can achieve, the following comparative example is used for comparison.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com