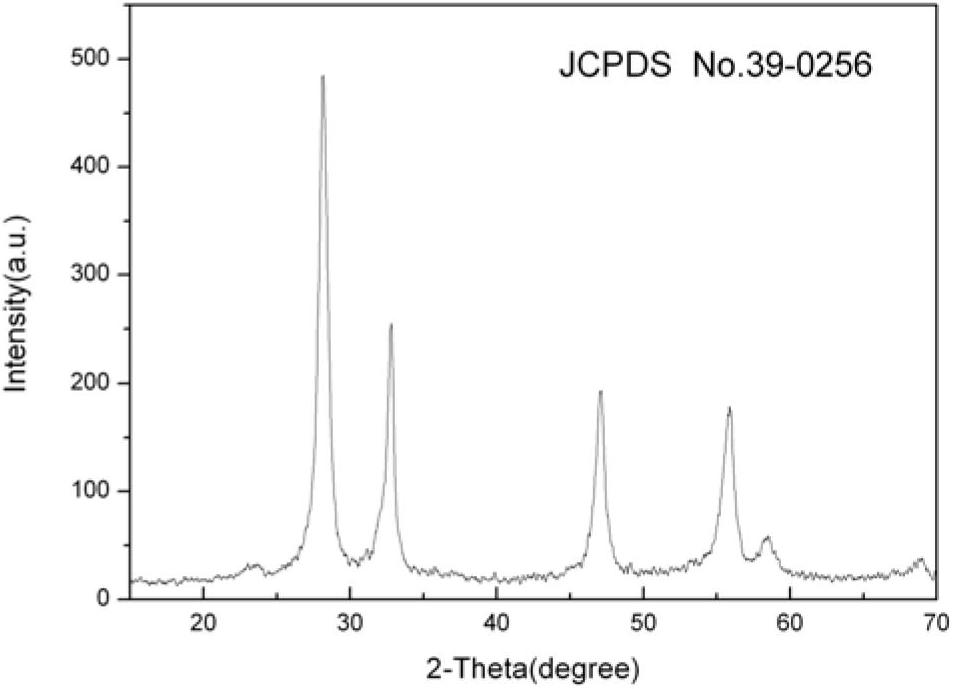

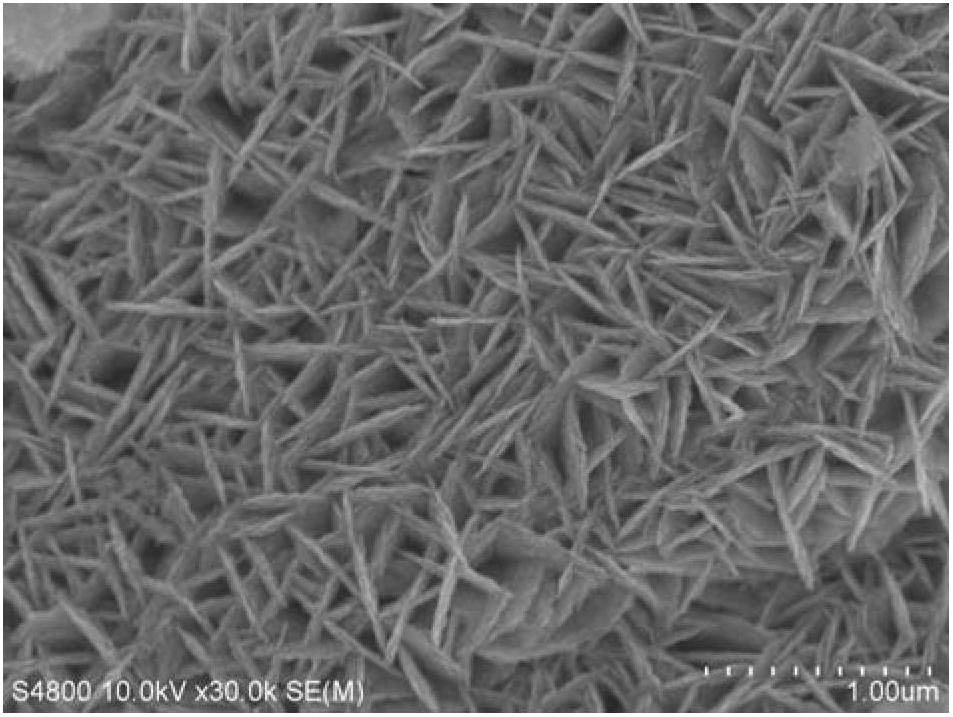

Preparation method of laminar-card-structure bisumth tungstate microcrystals

A bismuth tungstate and card technology, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of high energy consumption, small specific surface area, and reduced photocatalytic performance, and achieve low energy consumption and product crystallinity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) The analytically pure sodium tungstate dihydrate Na 2 WO 4 2H 2 O was added to deionized water to make a transparent solution A with a concentration of 0.037mol / L;

[0019] 2) At room temperature, add analytically pure bismuth nitrate pentahydrate Bi(NO 3 ) 3 ·5H 2 O, stir evenly so that the molar ratio of W / Bi in the solution is 1.3:2 to obtain solution B;

[0020] 3) Use NaOH solution with a concentration of 2mol / L to adjust the pH of solution B to 3.8 to obtain white suspension C;

[0021] 4) Pour the solution C into the hydrothermal reaction kettle, control the filling degree to 50%, the temperature of the hydrothermal reaction is 120°C, and the reaction time is 20h;

[0022] 5) Open the hydrothermal reaction kettle, the product is collected by centrifugation, and then washed twice with deionized water and absolute ethanol respectively, and dried at 40°C in an electric blast drying oven to obtain the final product with a sheet-like card structure Bi 2 WO ...

Embodiment 2

[0024] 1) The analytically pure sodium tungstate dihydrate Na 2 WO 4 2H 2 O was added to deionized water to make a transparent solution A with a concentration of 0.073mol / L;

[0025] 2) At room temperature, add analytically pure bismuth nitrate pentahydrate Bi(NO 3 ) 3 ·5H 2 O, stir evenly so that the molar ratio of W / Bi in the solution is 1.4:2 to obtain solution B;

[0026] 3) Adjust the pH of solution B to 4 with NaOH solution with a concentration of 4mol / L to obtain white suspension C;

[0027] 4) Pour the solution C into the hydrothermal reaction kettle, control the filling degree to 60%, the temperature of the hydrothermal reaction is 140°C, and the reaction time is 16h;

[0028] 5) Open the hydrothermal reaction kettle, the product is collected by centrifugation, and then washed three times with deionized water and absolute ethanol respectively, and dried at 60°C in an electric blast drying oven to obtain the final product sheet-like card structure Bi 2 WO 6 Mic...

Embodiment 3

[0030] 1) The analytically pure sodium tungstate dihydrate Na 2 WO 4 2H 2 O was added to deionized water to make a transparent solution A with a concentration of 0.146mol / L;

[0031] 2) At room temperature, add analytically pure bismuth nitrate pentahydrate Bi(NO 3 ) 3 ·5H 2 O, stir evenly so that the molar ratio of W / Bi in the solution is 1.5:2 to obtain solution B;

[0032] 3) Use NaOH solution with a concentration of 6mol / L to adjust the pH of solution B to 4.5 to obtain white suspension C;

[0033] 4) Pour the solution C into the hydrothermal reaction kettle, control the filling degree to 70%, the temperature of the hydrothermal reaction is 160°C, and the reaction time is 12h;

[0034] 5) Open the hydrothermal reaction kettle, the product is collected by centrifugation, and then washed 4 times with deionized water and absolute ethanol respectively, and dried at 70°C in an electric blast drying oven to obtain the final product sheet-like card structure Bi 2 WO 6 Mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com