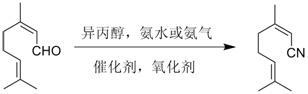

Method for preparing lemonile by using citral and device of preparation method

A production method and technology of citral, which are applied in the production method and device field of citral for preparing citric nitrile, can solve the problems of citral double bond oxidation side reaction, high energy consumption of repeated condensation, high ammoniation reaction temperature, etc., and achieve product The effect of good quality, low production cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

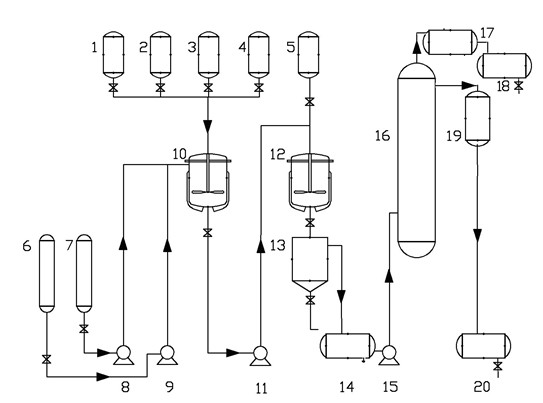

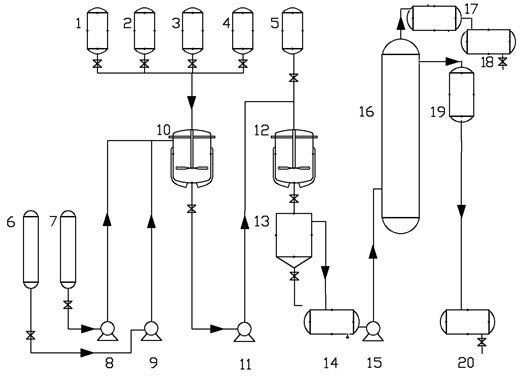

[0021] Embodiment 1: the production device embodiment of citral preparation citric nitrile

[0022] refer to figure 1 , the production plant embodiment that citral of the present invention prepares citric nitrile mainly consists of isopropanol storage tank 1, citral storage tank 2, ammonia water storage tank 3, hydrogen peroxide storage tank 4, ethyl acetate storage tank 5, oxygen storage tank 6, Ammonia storage tank 7, air pump 8. Air pump 9. Reaction tank 10. Conveyor pump 11. Extraction tank 12, oil-water separator 13, intermediate storage tank 14, feeding pump 15. Distillation tower 16. Condensation cooler 17. Ethyl acetate recovery tank 18. Condensation cooler 19. Composition of product storage tank 20, heating, cooling and vacuum systems. The outlets of isopropanol storage tank 1, citral storage tank 2, ammonia water storage tank 3, and hydrogen peroxide storage tank 4 are respectively connected to the top inlet of reaction tank 10, and the bottom outlet of r...

Embodiment 2

[0027] The present embodiment provides a kind of production method that citral prepares citric nitrile, comprises the following steps:

[0028] (1) Ammonification reaction: Add 30 kg of activated CuCl catalyst in the reaction tank 10, open the discharge valve at the lower part of the citral storage tank 2, add 1000 kg of citral to the reaction tank 10, and start the reaction tank 10 agitator, open the discharge valve at the lower part of the isopropanol storage tank 1 at the same time, add 4000 kg of isopropanol to the reaction tank 10 to dissolve citral; , slowly add ammonia water with a mass fraction of 20%, and control the amount of ammonia water added to be the number of moles of ammonia: the number of moles of citral is 1.1. After the addition is completed, react for 30 minutes to end the ammoniation reaction.

[0029] (2) Oxidation reaction: Adjust the temperature of the material in the reaction tank 10 to -10°C, open the lower valve of the hydrogen peroxide storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com