Carbon quantum dot-poly N-isopropylacrylamide composite material and preparation method thereof

A technology of isopropylacrylamide and carbon quantum dots, which can be used in luminescent materials, chemical instruments and methods, pharmaceutical formulations, etc., and can solve the problems of few researches on carbon quantum dots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

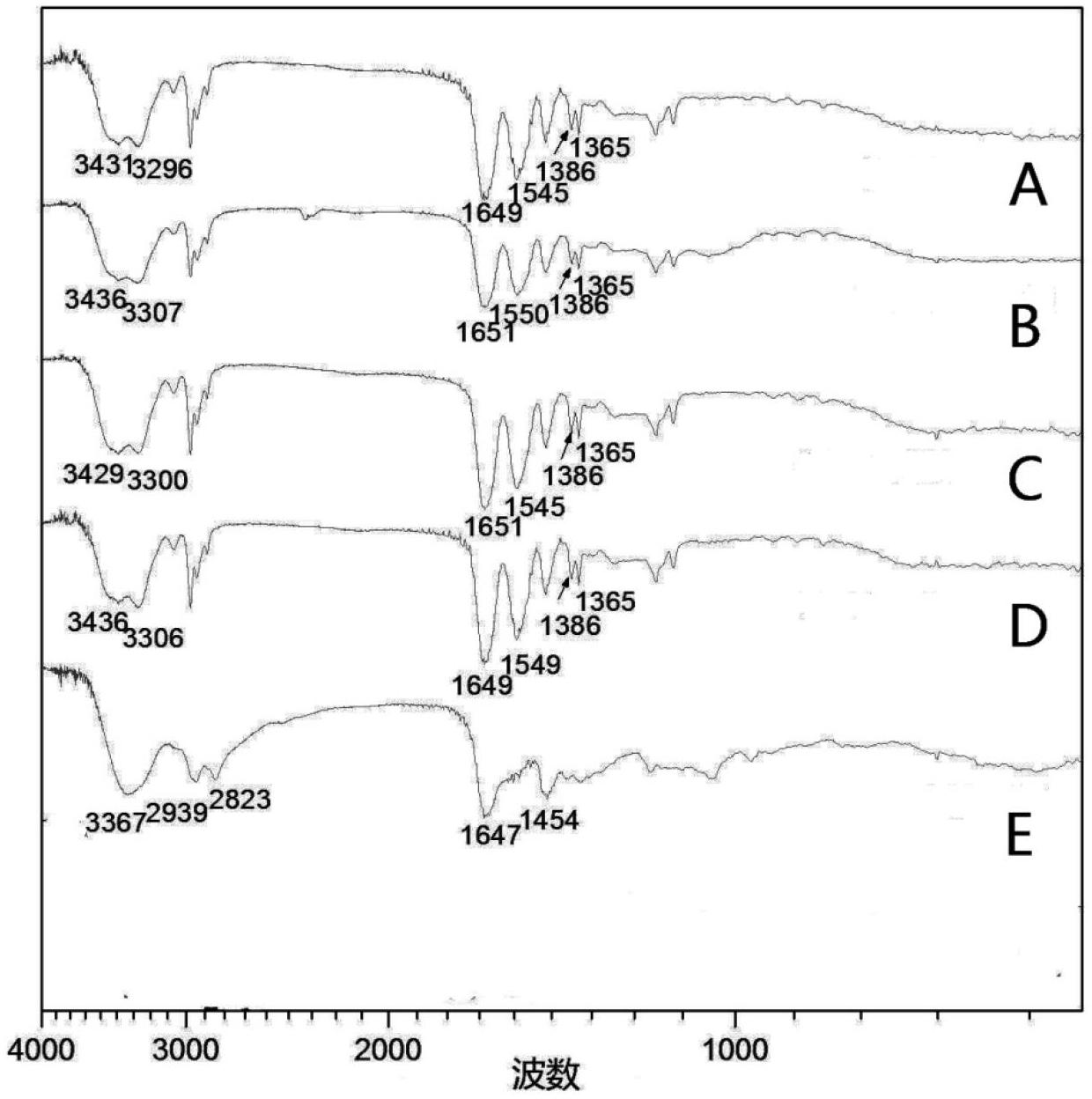

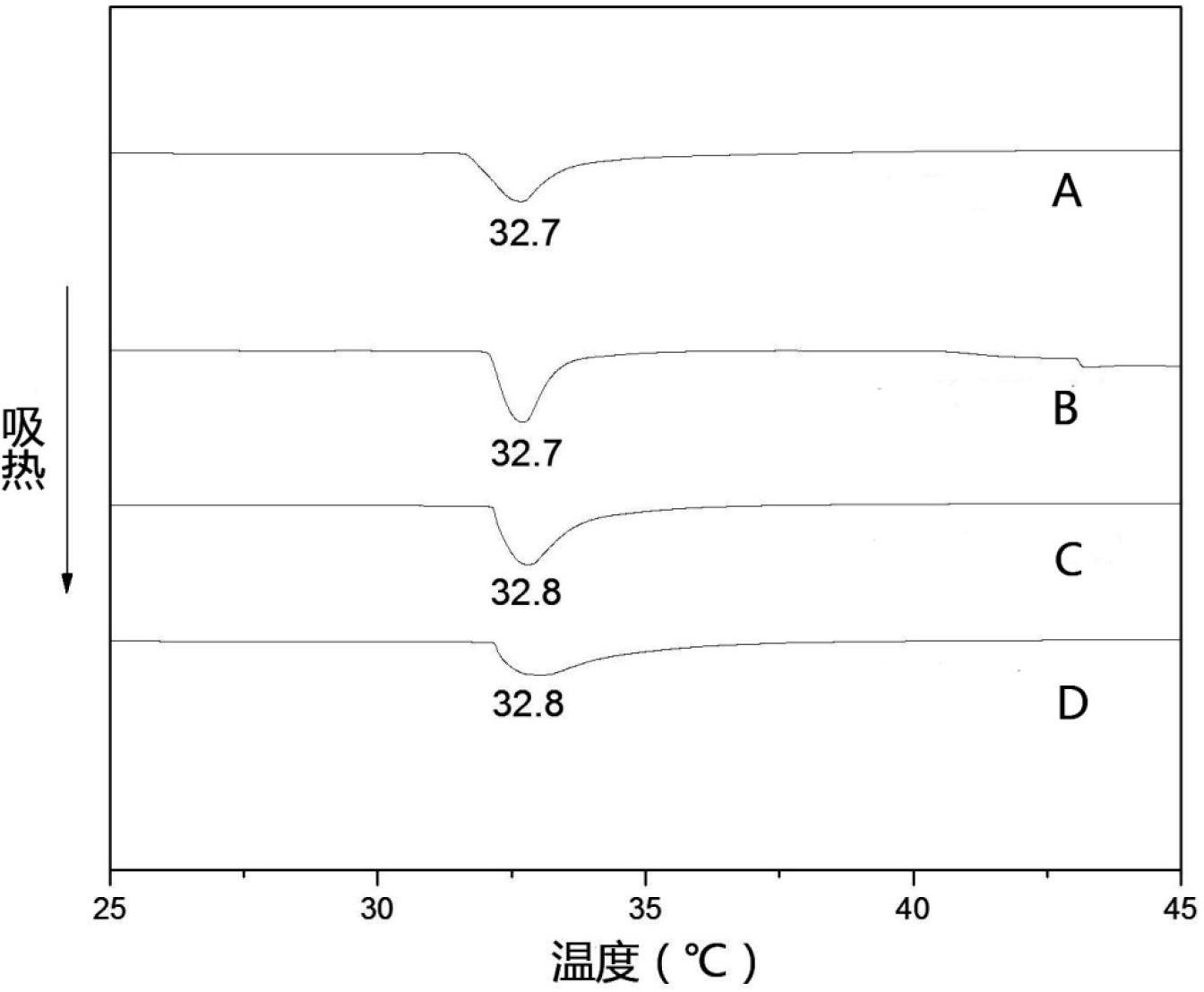

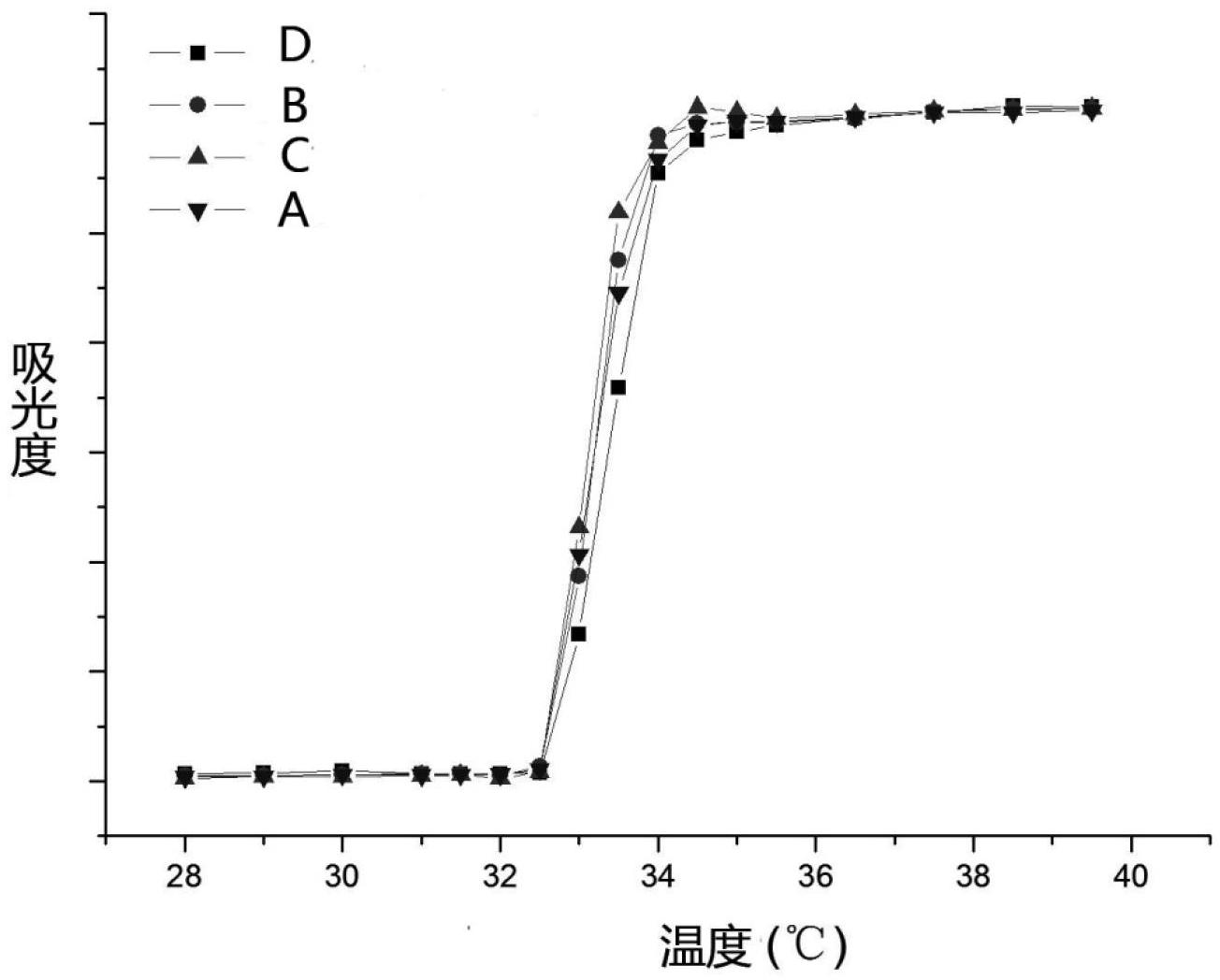

Method used

Image

Examples

Embodiment 1

[0026] Add 120ml of glycerol and 4g of polyethyleneimine (PEI, Mw800) into a 250ml round bottom flask, then add 20ml of phosphate solution (pH 7.4) with a concentration of 10mM, and stir vigorously to form a uniform solution. Place the flask containing the clear solution on the rotating platform of a 700W microwave oven and microwave for 10 minutes. After cooling, the obtained brown solution was diluted, and then dialyzed in deionized water with a dialysis bag (molecular weight cut-off 1000), and the water was changed every 8 hours. After dialysis for 3 days, it was freeze-dried to obtain carbon quantum dot nanoparticles (CD, the yield was 51 %).

[0027] Add 50ml of a solution containing 2g of carbon quantum dots and 376g (2.25mmol) of 2-bromoisobutyric acid into a 150ml flask, and adjust the pH to 5.0 with hydrochloric acid. After that, 0.259 g (2.25 mmol) of NHS and 0.431 g (2.25 mmol) of EDC·HCl were added to the mixed solution, and stirred at room temperature for 24 hour...

Embodiment 2

[0030] Add 120ml of glycerol and 4g of polyethyleneimine (PEI, Mw800) into a 250ml round bottom flask, then add 20ml of phosphate solution (pH 7.4) with a concentration of 10mM, and stir vigorously to form a uniform solution. Place the flask containing the clear solution on the rotating platform of a 700W microwave oven and microwave for 10 minutes. After cooling, the obtained brown solution was diluted, and then dialyzed in deionized water with a dialysis bag (molecular weight cut-off 1000), and the water was changed every 8 hours. After 3 days of dialysis, it was freeze-dried to obtain carbon quantum dot nanoparticles (CD, the yield was 51 %).

[0031] Add 50ml of a solution containing 2g of carbon quantum dots and 376g (2.25mmol) of 2-bromoisobutyric acid into a 150ml flask, and adjust the pH to 5.0 with hydrochloric acid. Afterwards, 0.259 g (2.25 mmol) of NHS and 0.431 g (2.25 mmol) of EDC·HCl were added to the mixed solution, and stirred at room temperature for 24 hours...

Embodiment 3

[0034] Add 120ml of glycerol and 4g of polyethyleneimine (PEI, Mw800) into a 250ml round bottom flask, then add 20ml of phosphate solution (pH 7.4) with a concentration of 10mM, and stir vigorously to form a uniform solution. Place the flask containing the clear solution on the rotating platform of a 700W microwave oven and microwave for 10 minutes. After cooling, the obtained brown solution was diluted, and then dialyzed in deionized water with a dialysis bag (molecular weight cut-off 1000), and the water was changed every 8 hours. After 3 days of dialysis, it was freeze-dried to obtain carbon quantum dot nanoparticles (CD, the yield was 51 %).

[0035] Add 50ml of a solution containing 2g of carbon quantum dots and 376g (2.25mmol) of 2-bromoisobutyric acid into a 150ml flask, and adjust the pH to 5.0 with hydrochloric acid. Afterwards, 0.259 g (2.25 mmol) of NHS and 0.431 g (2.25 mmol) of EDC·HCl were added to the mixed solution, and stirred at room temperature for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com