Nano composite ice-covering-proof coating containing phase change silicone oil and preparation method thereof

A nano-composite, anti-icing technology, applied in chemical instruments and methods, coatings, other chemical processes, etc., can solve the problems of alkane supercooling restricting practical applications, achieve good anti-icing effect, simple preparation process, Easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

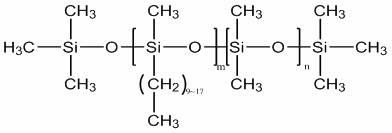

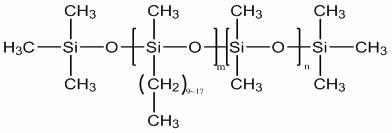

[0031] Weigh 8.5g of PHMS and 7.0g of C 14 Add olefin to a four-necked bottle equipped with a condenser, pass nitrogen gas for 20 minutes to remove the air, and then raise the temperature to 30 °C under the protection of nitrogen atmosphere. C, 3 μl Karstedt catalyst was added. After the reaction started, because the exothermic temperature began to rise, after the temperature was constant, 13.5g of C was added dropwise to the reaction system. 12 Alkene, after the dropwise addition, with 2 C / min heating rate to adjust the reaction temperature to 103 C, reaction 3h, decompression distillation removes unreacted C 14 alkenes and C 12 ene, to obtain a colorless transparent viscous phase change silicone oil (PCS).

[0032] Weigh 2g SiO 2 Disperse in an appropriate amount of xylene or toluene, add 8g of 107 glue (hydroxyl-terminated polydimethylsiloxane), disperse for 5min at 15000rpm with a homodisperser; then add 4 drops of dibutyltin dilaurate catalyst, stir evenly with m...

Embodiment 2

[0036] Weigh 6.0g of PHMS and 5.4g of C 14 Add olefin to a four-necked bottle equipped with a condenser, pass nitrogen gas for 20 minutes to remove the air, and then raise the temperature to 30 °C under the protection of nitrogen atmosphere. C, 2 μl Karstedt catalyst was added. After the reaction started, due to the exothermic temperature began to rise, after the temperature was constant, 9.5g of C was added dropwise to the reaction system. 12 Alkene, after the dropwise addition, with 2 The heating rate of C / min adjusts the reaction temperature to 93 C, reaction 2h, decompression distillation removes unreacted C 14 alkenes and C 12 ene, to obtain a colorless transparent viscous phase change silicone oil (PCS).

[0037] Weigh 1g SiO2 2Disperse in an appropriate amount of xylene, add 6g of 107 glue, and disperse with a homodisperser at 10,000 rpm for 7 minutes; then add 4 drops of dibutyltin dilaurate catalyst, and stir evenly with magnetic force.

[0038] Mix 1.0g of ...

Embodiment 3

[0041] Weigh 10 g of PHMS and 8.2 g of C 14 Add olefin to a four-necked bottle equipped with a condenser, pass nitrogen gas for 20 minutes to remove the air, and then raise the temperature to 30 °C under the protection of nitrogen atmosphere. C, 4 μl Karstedt catalyst was added. After the reaction started, due to the exothermic temperature began to rise, after the temperature was constant, 16.3g of C was added dropwise to the reaction system. 12 Alkene, after the dropwise addition, with 2 The heating rate of C / min adjusts the reaction temperature to 97 C, reaction 4h, decompression distillation removes unreacted C 14 alkenes and C 12 ene, to obtain a colorless transparent viscous phase change silicone oil (PCS).

[0042] Weigh 3g SiO 2 Disperse in an appropriate amount of xylene, add 10g of 107 glue, and disperse with a homogeneous disperser at 170 million rpm for 7 minutes; then add 5 drops of dibutyltin dilaurate catalyst, and stir evenly with magnetic force.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com