Fatty alcohol-polyoxyethylene ether propionate surfactant and preparation method thereof and application thereof to tertiary recovery

A technology of alcohol polyoxyethylene ether propionate and surfactant, which is applied in the field of fatty alcohol polyoxyethylene ether propionate surfactant, can solve the problems of limited research results and few types, and achieves simple synthesis conditions and biological Good degradation performance and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

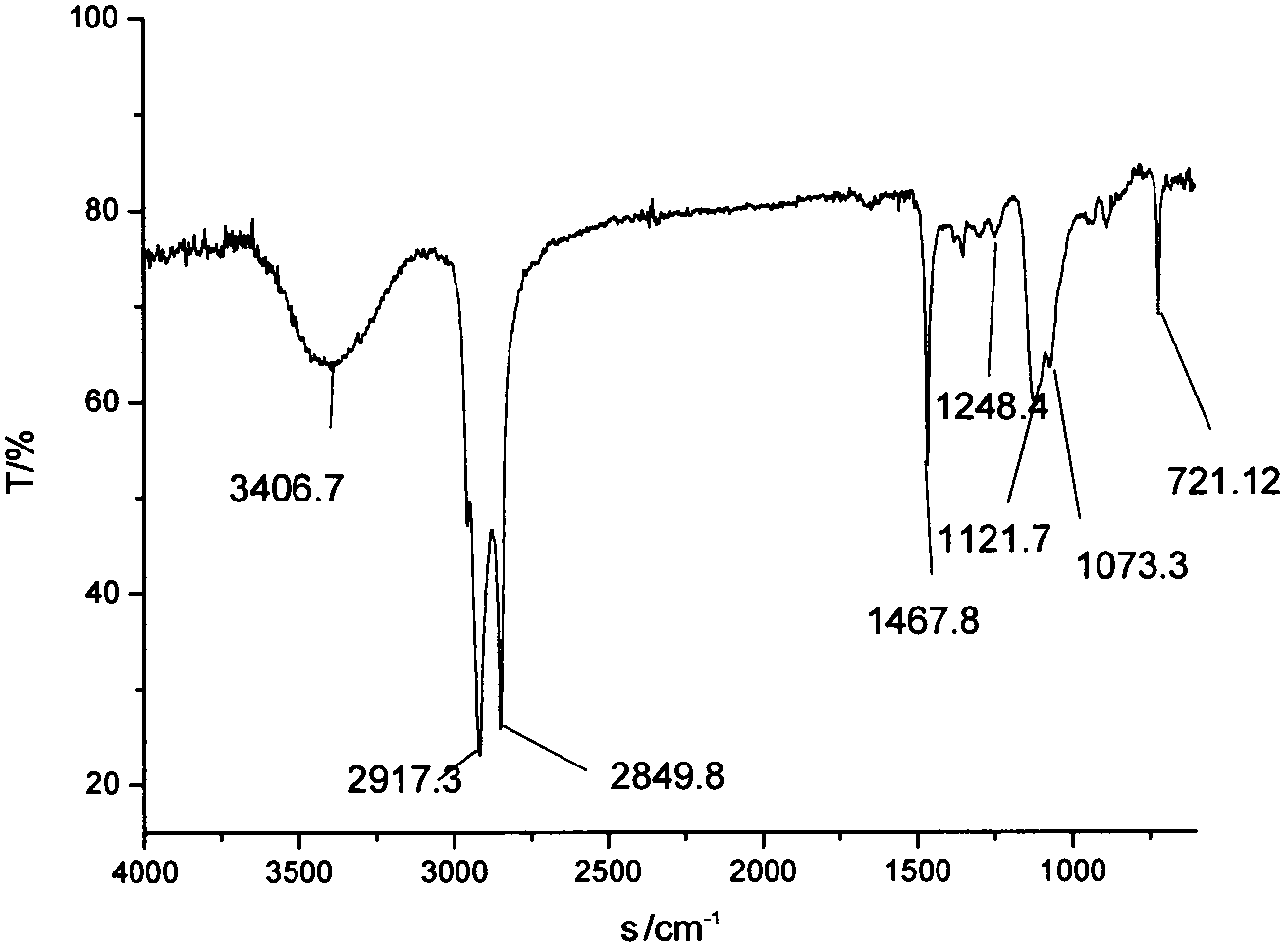

[0033] Fatty alcohol polyoxyethylene ether and methyl acrylate (n (fatty alcohol polyoxyethylene ether): n (methyl acrylate) = 1: 2) react under the action of KOH, wherein, methyl acrylate is fed by dropping , the dropping temperature is about 60°C, and the dropping time is about 1h. After the dropping is completed, the temperature is raised to about 70°C, and the reaction is about 8h. After the reaction is completed, it is filtered, washed, recrystallized, and dried to obtain the intermediate Fatty alcohol polyoxyethylene ether methyl propionate, the product is brown yellow solid.

[0034] Add the intermediate in a dry three-necked flask, heat to about 60°C, add dropwise 20% sodium hydroxide solution, stir at a molar ratio of 1:1, heat, control the reflux temperature at about 80°C, and adjust the pH value to 8~ 9. After reacting for 2 hours, finish the reaction, filter, wash, and dry overnight at 100°C under vacuum (vacuum degree is about 2.5kPa) to obtain fatty alcohol polyo...

Embodiment 2

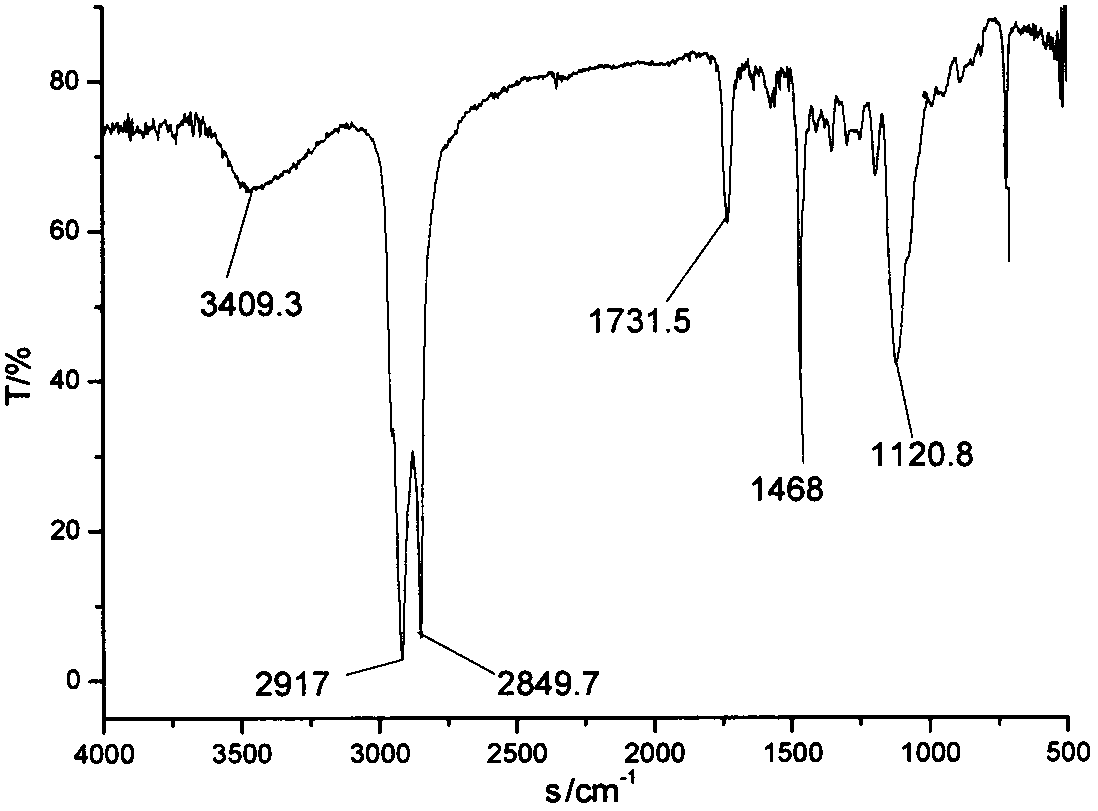

[0037] Fatty alcohol polyoxyethylene ether and methyl acrylate (n (fatty alcohol polyoxyethylene ether): n (methyl acrylate) = 1: 3) react under the action of KOH, wherein, methyl acrylate is fed in a dropwise manner , the dropping temperature is about 60°C, and the dropping time is about 1h. After the dropping is completed, the temperature is raised to about 80°C, and the reaction is about 13h. After the reaction is completed, it is filtered, washed, recrystallized, and dried to obtain the intermediate Fatty alcohol polyoxyethylene ether methyl propionate, the product is brown yellow solid.

[0038] Add the intermediate in a dry three-necked flask, heat to about 60°C, add dropwise 15% sodium hydroxide solution, stir at a molar ratio of 1:1, heat, control the reflux temperature at about 90°C, and adjust the pH value to 8~ 9. After reacting for 3 hours, finish the reaction, filter, wash, and dry overnight at 100° C. under vacuum (vacuum degree is about 2.5 kPa) to obtain fatty ...

Embodiment 3

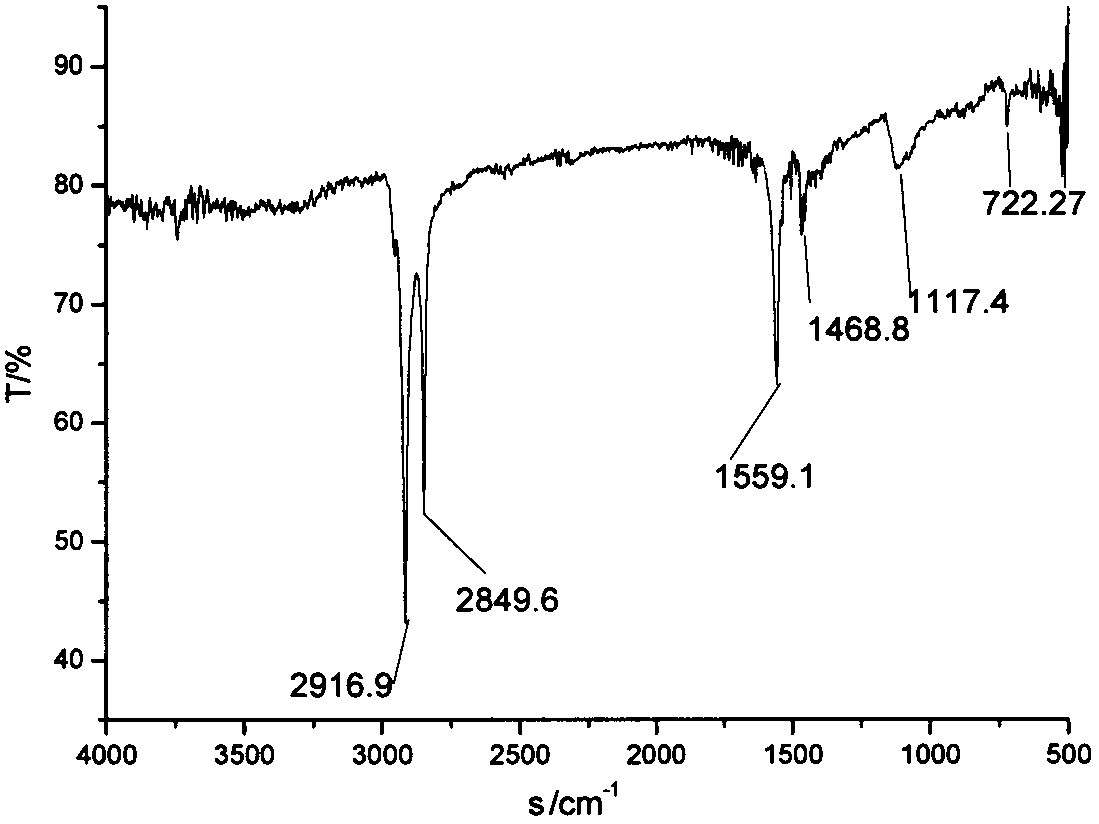

[0041] Fatty alcohol polyoxyethylene ether and methyl acrylate (n (fatty alcohol polyoxyethylene ether): n (methyl acrylate) = 1: 4) react under the action of KOH, wherein, methyl acrylate is fed by dropwise , the dropping temperature is about 60°C, and the dropping time is about 1h. After the dropping is completed, the temperature is raised to about 80°C, and the reaction is about 22h. After the reaction is completed, it is filtered, washed, recrystallized, and dried to obtain the intermediate Fatty alcohol polyoxyethylene ether methyl propionate, the product is brown yellow solid.

[0042] Add the intermediate to a dry three-necked flask, heat it to about 60°C, add dropwise 20% sodium hydroxide solution, stir at a molar ratio of 1:1, heat, control the reflux temperature at about 90°C, and adjust the pH value to 8~ 9. After reacting for 4 hours, finish the reaction, filter, wash, and dry overnight at 100° C. under vacuum (vacuum degree is about 2.5 kPa) to obtain fatty alcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com