Visible photosensitized periodic mesoporous organosilica (PMO) near-infrared luminescence material grated with rare earth complex

A technology of rare earth complexes and luminescent materials, applied in the direction of luminescent materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

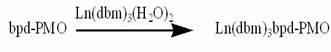

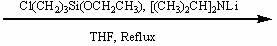

[0027] (1) Prepare 1.5 g 4,4'-dimethyl-2,2'-bipyridine; prepare 40 mL tetrahydrofuran, dissolve 4,4'-dimethyl-2,2'-bipyridine, and Cool the solution to -20°C; prepare 8.2 mL lithium diisopropylamide, add it dropwise to the above solution, and stir the mixture at -20°C for 2 hours; prepare 4 mL Cl(CH 2 )Si(OEt) 3 , which is added, and the N 2 Stir under protection for 24 hours; distill under reduced pressure to obtain a light rose crude product; vacuum-dry the crude product obtained by distillation under reduced pressure at room temperature to obtain a solid product one.

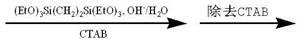

[0028] (2) Prepare 32 mL of deionized water, 1.04 g of cetyltrimethylammonium bromide and 0.5 g of sodium hydroxide; add the cetyltrimethylammonium bromide and sodium hydroxide to the deionized water , magnetic stirring to accelerate its dissolution, to prepare the first mixture; prepare 1.8 mL of 1,2-bis(triethoxysilyl)ethane and 0.15 g of silanized 2,2'-bipyridyl, to prepare the second mixture solution; ...

Embodiment 2

[0033] (1) Prepare 1.5 g 4,4'-dimethyl-2,2'-bipyridine; prepare 40 mL tetrahydrofuran, dissolve 4,4'-dimethyl-2,2'-bipyridine, and Cool the solution to -20°C; prepare 8.2 mL lithium diisopropylamide, add it dropwise to the above solution, and stir the mixture at -20°C for 2 hours; prepare 4 mL Cl(CH 2 )Si(OEt) 3 , which is added, and the N 2 Stir under protection for 24 hours; distill under reduced pressure to obtain a light rose crude product; vacuum-dry the crude product obtained by distillation under reduced pressure at room temperature to obtain a solid product one.

[0034] (2) Prepare 32 mL of deionized water, 1.04 g of cetyltrimethylammonium bromide and 0.5 g of sodium hydroxide; add the cetyltrimethylammonium bromide and sodium hydroxide to the deionized water , magnetic stirring to accelerate its dissolution, to prepare the first mixture; prepare 1.8 mL of 1,2-bis(triethoxysilyl)ethane and 0.15 g of silanized 2,2'-bipyridyl, to prepare the second mixture solution; ...

Embodiment 3

[0039] (1) Prepare 1.5 g 4,4'-dimethyl-2,2'-bipyridine; prepare 40 mL tetrahydrofuran, dissolve 4,4'-dimethyl-2,2'-bipyridine, and Cool the solution to -20°C; prepare 8.2 mL lithium diisopropylamide, add it dropwise to the above solution, and stir the mixture at -20°C for 2 hours; prepare 4 mL Cl(CH 2 )Si(OEt) 3 , which is added, and the N 2 Stir under protection for 24 hours; distill under reduced pressure to obtain a light rose crude product; vacuum-dry the crude product obtained by distillation under reduced pressure at room temperature to obtain a solid product one.

[0040] (2) Prepare 32 mL of deionized water, 1.04 g of cetyltrimethylammonium bromide and 0.5 g of sodium hydroxide; add the cetyltrimethylammonium bromide and sodium hydroxide to the deionized water , magnetic stirring to accelerate its dissolution, to prepare the first mixture; prepare 1.8 mL of 1,2-bis(triethoxysilyl)ethane and 0.15 g of silanized 2,2'-bipyridyl, to prepare the second mixture solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com