High-sugar and high-acid resistant lactobacillus

A Lactobacillus, high sugar and high acid technology, applied in the field of microorganisms, can solve the problems of low optical purity, low L-lactic acid conversion rate, etc., achieve high fermentation efficiency, improve sugar conversion rate and lactic acid production rate, and good physiological and biochemical functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

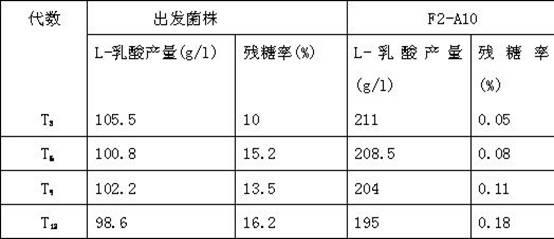

[0021] Example 1 The preparation method of lactobacillus provided by the present invention.

[0022] one. Materials and Methods

[0023] 1. Strain: Lactobacillus delbrueckii (laboratory preservation strain, self-named F-A10)

[0024] 2. Medium formulation and culture conditions

[0025] Separation and detection medium--GYP medium: glucose 1.0g, yeast extract 1.0g, peptone 0.5g, meat juice extract 0.2g, NaAc 3H 2 O 0.2g, MgSO 4 7H 2 O 20mg, MnSO 4 4H 2 O 1mg, FeSO 4 7H 2 O 1mg, NaCl 1mg, Tween 80 analytical grade 0.5ml, agar 1.2g, CaCO 30 0.5g, water 100ml; culture conditions: temperature 121°C, culture time 20min.

[0026] Seed medium formula (unit: g / l): glucose 50, yeast extract 10, peptone 10, gravy extract 0.2, NaAc 3H 2 O 0.5, MgSO 4 7H 2 O 0.2, MnSO 4 4H 2 O 0.01, FeSO 4 7H 2 O 0.01 NaCl 0.01; culture conditions: PH=4.0-5.0, temperature 121°C, culture time 20min.

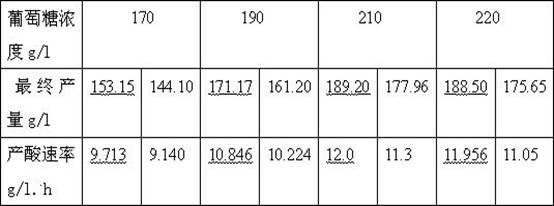

[0027] Fermentation medium formula (unit: g / l): glucose 200, ammonium sulfate 1.44, d...

Embodiment 2

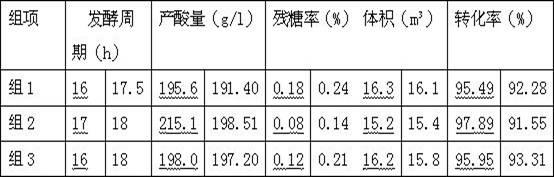

[0073] The screened strains were connected to 150m 3 Fermentation in a fermenter, the fermentation temperature is 54°C, sodium hydroxide is used as the neutralizing agent, the stirring speed is 55-65r / min, and the pH is 4.0-5.0.

[0074] The culture medium adopts fermentation medium, formula (unit: g / l): glucose 200, ammonium sulfate 1.44, dipotassium hydrogen phosphate 0.08, potassium dihydrogen phosphate 0.08, yeast extract 0.2; culture conditions: PH=4.0-5.0, temperature 121 ℃, the incubation time was 20 min. The results are shown in Table 8.

[0075] group item Period (h) Acid production (g / l) Residual sugar rate (%) Volume (m3) Conversion rate(%) Optical purity (%) Group 7 23.5 192.5 0.09 124.5 97.29 99.38 Group 8 22.5 190.5 0.11 128 97.30 99.42 Group 9 23 189.8 0.10 127.5 95.51 99.39

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com