Scraping-cutting and impacting combined type drill

A compound drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of shortening the service life of drill bits, poor wear balance of cutting teeth, and PDC teeth falling out of the bottom of the well, so as to improve the efficiency of impact rock breaking , to avoid rapid wear, to avoid the effect of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

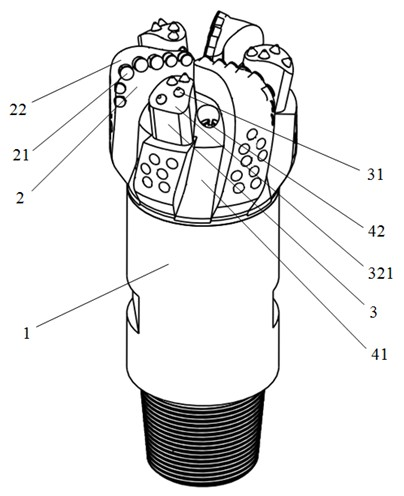

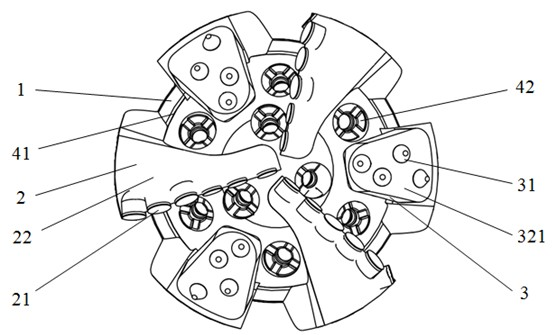

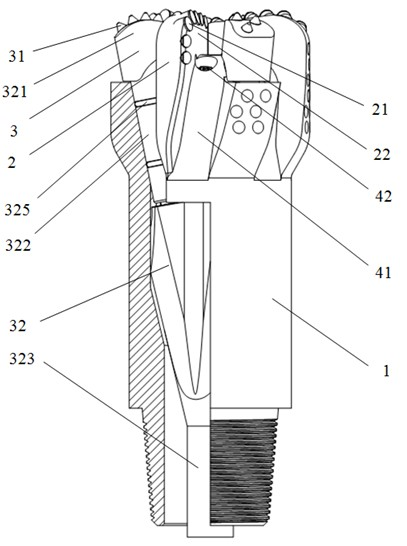

[0068] Such as Figure 1 to Figure 4 , Figure 10 , Figure 17 and Figure 23 As shown, a scraping-impact composite drill bit includes a drill body 1, on which a fixed cutting structure 2, an impact cutting structure 3 and a hydraulic structure composed of a flow channel 41 and a nozzle 42 are arranged, and the fixed cutting structure 2 Including fixed cutting teeth 21, the impact cutting structure 3 includes a force transmission mechanism 32 for transmitting impact force and an impact cutting tooth 31, the force transmission mechanism 32 includes a punch 321, a dowel bar 322 and an anvil body 323, and the impact cutting tooth 31 is consolidated On the punch 321 at the end of the force transmission mechanism 32, the punch 321 can slide relative to the drill body 1 in the impact force transmission direction. The composite drill bit does not include an impact mechanism, but has three fixed blades 22 and three sets of impact cutting units, and the fixed blades 22 and punches 321...

Embodiment 2

[0070] This embodiment is basically the same as Embodiment 1, the difference is that there are two dowel bars in one or each impact cutting unit, and the two dowel bars have different motion laws and have relative motions between each other, wherein One dowel (one) 3221 is fixedly connected with the punch 321, the other dowel (two) 3222 is hinged with the anvil 323, and the two dowels are connected by a hinge (such as Figure 5 and Figure 18 shown). When the punch 321 is far away from the center of the drill bit and the included angle between the impact direction and the axis of the drill bit is relatively large, it is easier to realize the conversion of the impact direction and the transmission of the impact force by using two dowel bars hinged to each other. Anvil body centralizing sleeve 324 is provided between anvil body 323 and drill body 1 (as Figure 5 and Figure 6 shown), or directly process a surface on the anvil body 323 that forms a gap fit with the inner hole ...

Embodiment 3

[0072] This embodiment is basically the same as Embodiment 1 or Embodiment 2, and the difference is that the composite drill bit has 2 fixed blades 22, 2 sets of impact cutting units, and the fixed blades 22 and punches 321 are arranged alternately (such as Figure 8 shown). The use of fewer fixed blades and impact cutting units facilitates the downsizing of the drill bit and facilitates the application of composite drill bits in slim holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com