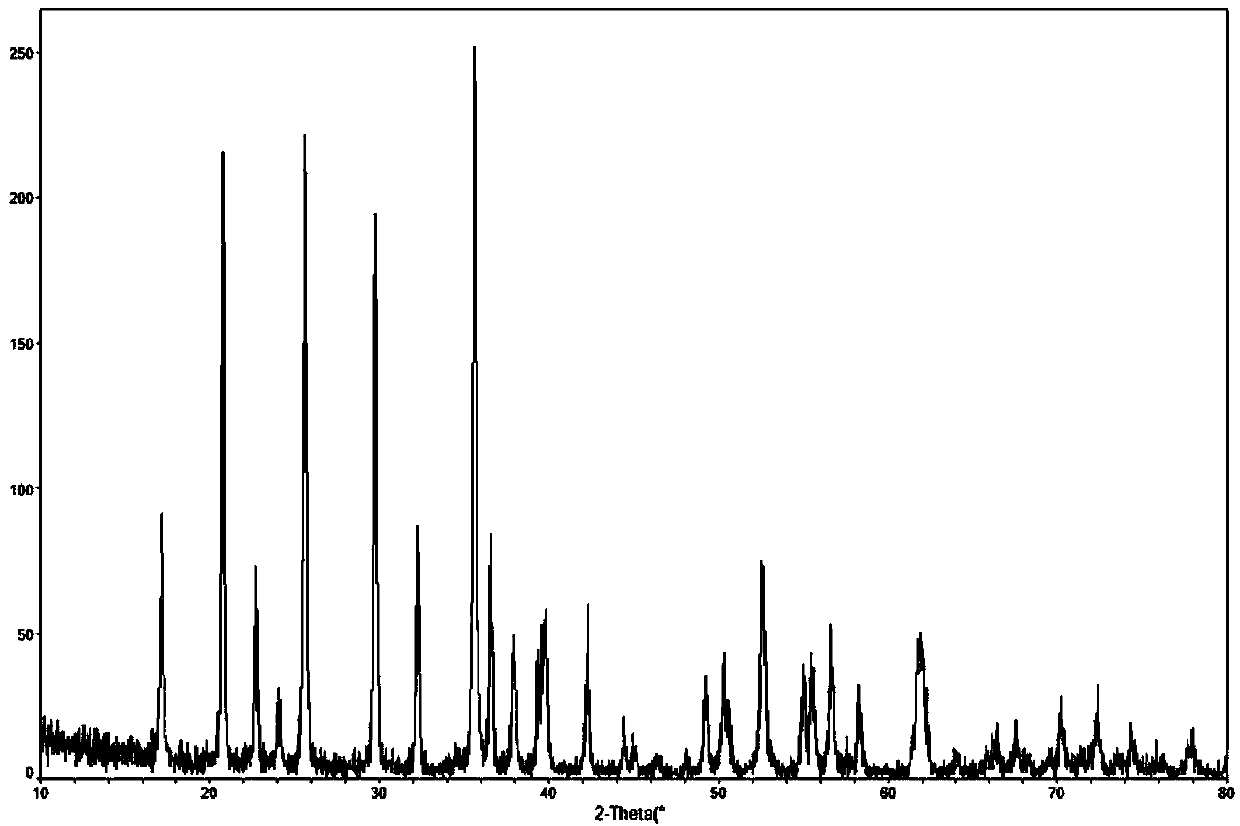

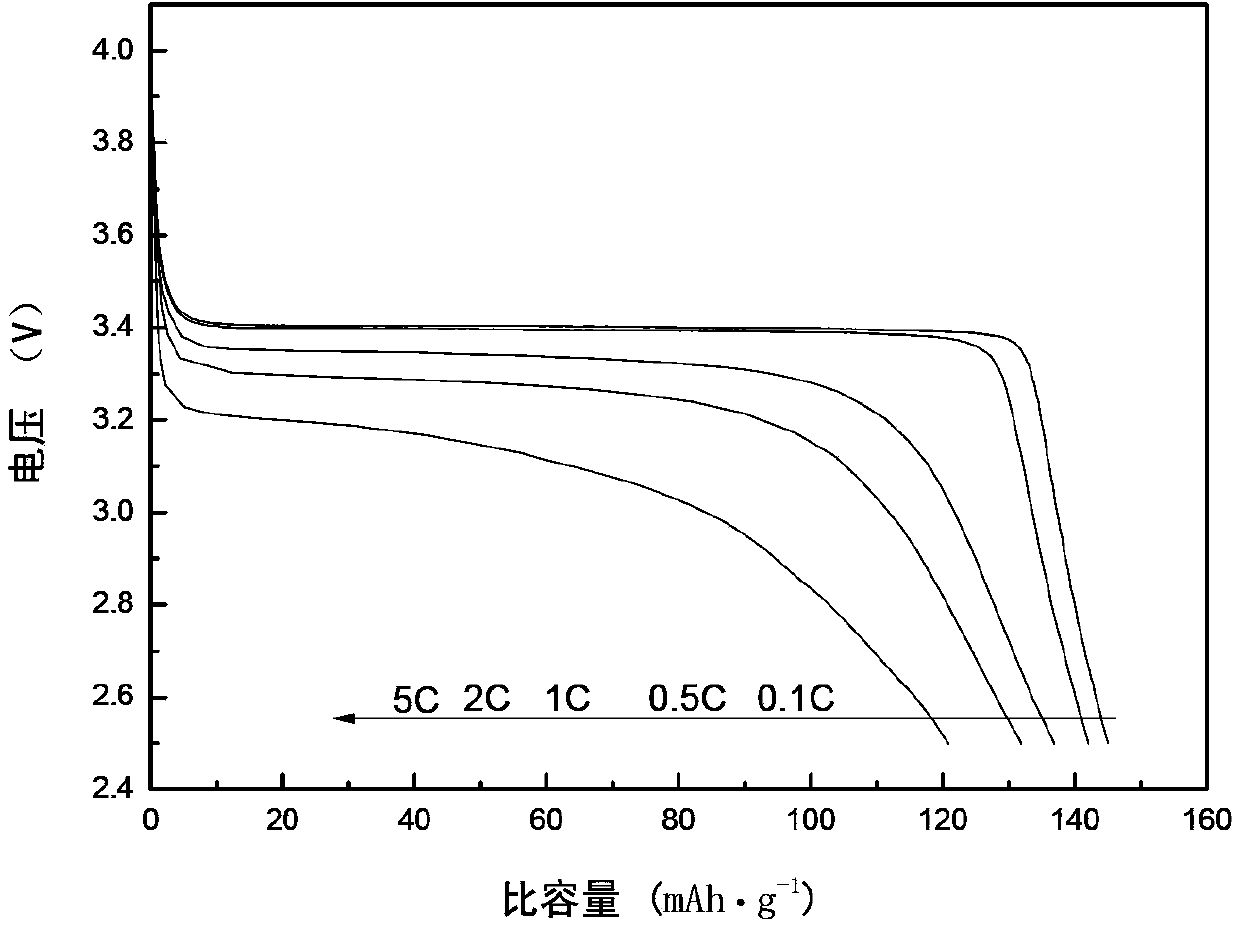

Preparation method of graphene-based LiFePO4/C composite material

A composite material, graphene-based technology, applied in graphene, graphite, chemical instruments and methods, etc., can solve problems such as poor rate performance and poor conductivity of lithium iron phosphate cathode materials, and achieve high specific capacity, easy control, and technology. Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Graphene oxide and ferric sulfate are dissolved in deionized water at a mass ratio of graphene oxide to iron element of 0.1:1 to prepare a mixed solution with an iron ion concentration of 1 mol / L, and then disperse by ultrasonic waves for 3 hours to obtain a dispersed solution. Iron salt solution with graphene oxide;

[0043] Prepare a phosphoric acid solution with a concentration of 1mol / L.

[0044] The iron salt solution and phosphoric acid solution dispersed with graphene oxide obtained above are added to the reactor with stirring according to the ratio of the amount of substances Fe: P = 1: 1.1, and the concentration is 1mol / L at the same time. Adjust the pH of the reaction feed liquid to 2.1, control the temperature to 60°C for 5 hours to react to obtain an emulsion, filter and wash the emulsion obtained above, and dry the filter cake in a blast drying oven at 80°C for 24 hours. Obtain iron phosphate / graphene oxide precursor;

[0045] The above-mentioned iron pho...

Embodiment 2

[0047] Graphene oxide and iron nitrate are dissolved in deionized water at a mass ratio of graphene oxide and iron element of 0.2:1 to prepare a mixed solution with an iron ion concentration of 0.5 mol / L, which is then dispersed by ultrasonic waves for 3 hours to obtain An iron salt solution dispersed with graphene oxide;

[0048] Prepare a solution of ammonium dihydrogen phosphate with a concentration of 0.5 mol / L.

[0049] The above obtained iron salt solution dispersed with graphene oxide and ammonium dihydrogen phosphate solution are added into the reactor with stirring according to the ratio of the amount of substances Fe:P=1:1, and at the same time, the concentration is 0.5mol / L of sodium hydroxide aqueous solution to adjust the pH of the reaction feed liquid to 2.5, control the temperature to 80 ° C for 3 hours to obtain an emulsion, filter and wash the above obtained emulsion, and place the filter cake at 80 ° C for air drying Dry in the oven for 24 hours to obtain t...

Embodiment 3

[0053] Use graphene oxide and ferrous sulfate to dissolve in deionized water at a mass ratio of graphene oxide to iron element of 0.3:1, and then add excess H 2 o 2 After oxidation, prepare a mixed solution with an iron ion concentration of 2mol / L, and then place it in ultrasonic dispersion for 3 hours to obtain an iron salt solution dispersed with graphene oxide;

[0054] Prepare a diammonium hydrogen phosphate solution with a concentration of 2 mol / L.

[0055] The above obtained iron salt solution dispersed with graphene oxide and diammonium hydrogen phosphate solution are added to the reactor with stirring according to the ratio of the amount of substances Fe: P=1: 1, and at the same time, the concentration is 5mol / L of sodium hydroxide aqueous solution to adjust the pH of the reaction feed liquid to 2.5, control the temperature to 80 ° C for 3 hours to obtain an emulsion, filter and wash the above obtained emulsion, and place the filter cake in an 80 ° C blast drying ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com