Colloid photonic crystal printing method based on magnetic field orientation control

A colloidal photonic crystal, orientation control technology, applied in printing, printing process, printing of special varieties of prints, etc., can solve problems such as few reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Synthesis of Colloidal Photonic Crystals

[0026] Raw material FeCl 3 (0.4mmol), surfactant PAA (4mmol) and solvent DEG (16mL) were mixed and heated to 220 degrees Celsius, reacted for one hour under nitrogen protection, injected with an appropriate amount of NaOH / DEG (1.8ml, 2.5mol / L) solution, at 220 The reaction was continued at °C for 1 hour. After the reaction, it was left to cool, washed three times by centrifugation with ethanol and water, and dispersed in 3 ml of deionized water.

[0027] Fe will be produced 3 O 4 The aqueous solution of the colloidal particles was mixed with 20 ml of ethanol and 1 ml of ammonia water, and 0.1 mL of TEOS was injected every 20 minutes under mechanical stirring, and the number of additions was set according to the design size of the colloidal particles. After the reaction is completed, it is washed and separated with ethanol, and the product is dispersed in 3 mL of ethanol to obtain a shell of SiO. 2 , with Fe inside 3 O 4 ...

Embodiment 2

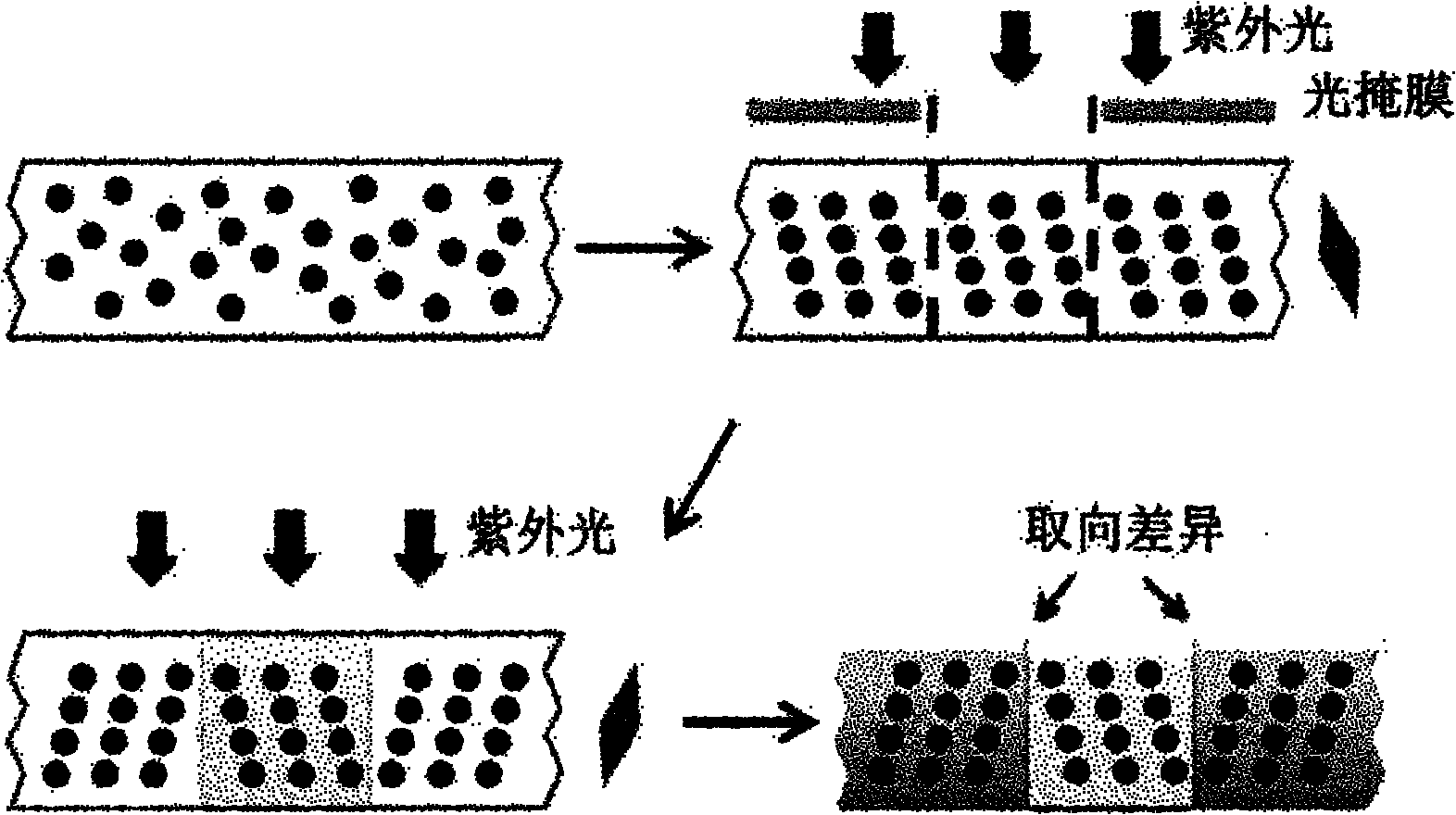

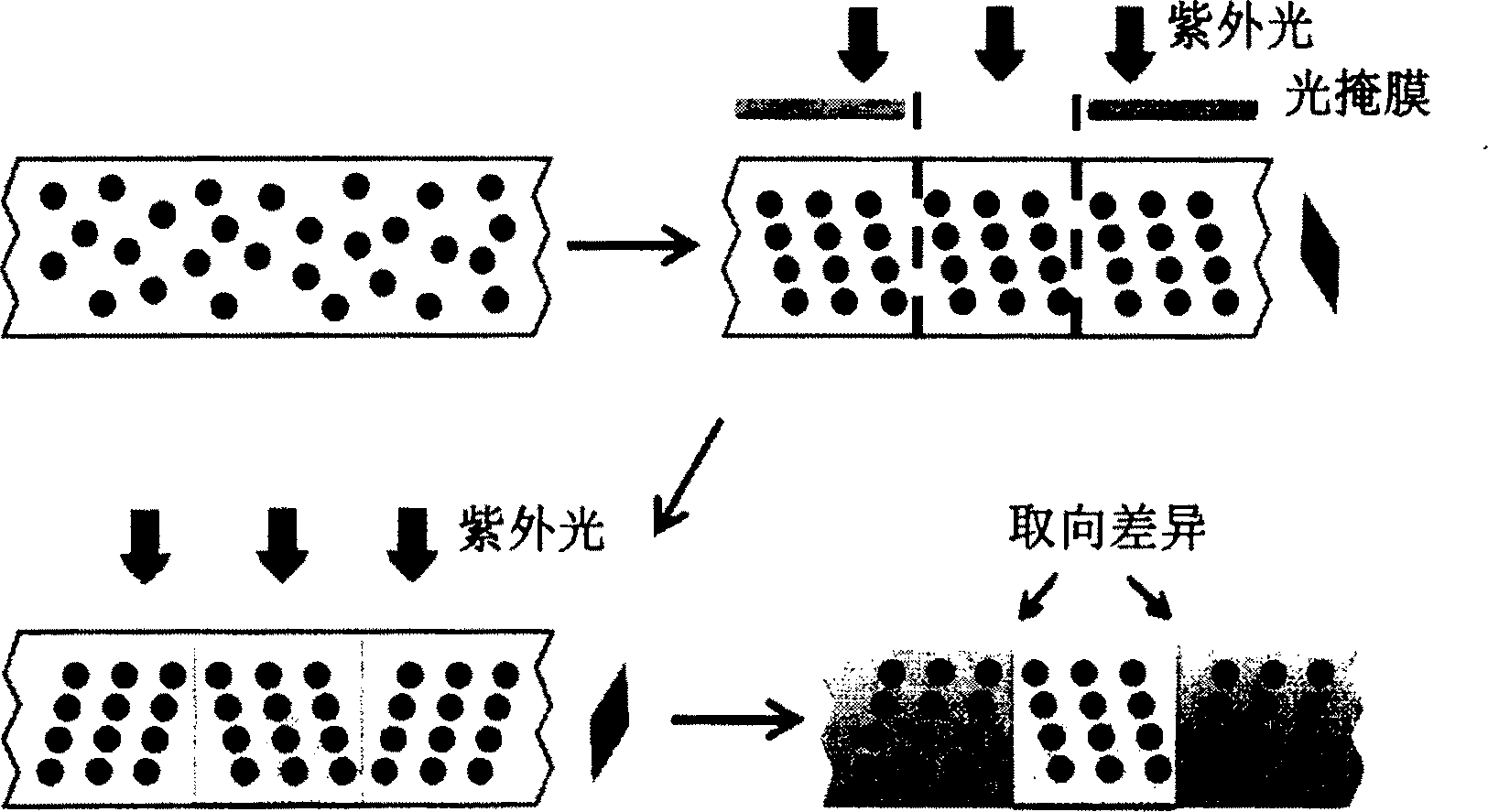

[0029] Orientation-controlled colloidal photonic crystal printing

[0030] The printing process of photonic crystal printing based on magnetic field orientation control is as follows figure 1 As shown, take an appropriate amount of shell as SiO 2 , with Fe inside 3 O 4 The core-shell colloidal particles were removed from the solvent, and dispersed in the same volume of PEGDA and PEGMA mixed solution, the volume ratio between the two was between 1:1 and 1:4, and the photoinitiator DMPA (5wt%) was added at the same time. Ultrasonic dispersion to make photonic crystal printing liquid. Take 25 μL of this solution and place it between the glass substrate and the hydrophobic cover glass with a distance of 230 μm, and place it above the inclined NdFeB magnet. Under the action of an external magnetic field, the magnetic colloidal particles form a chain-like one-dimensional photonic crystal structure, and the crystal The orientation is consistent with the direction of the external ...

Embodiment 3

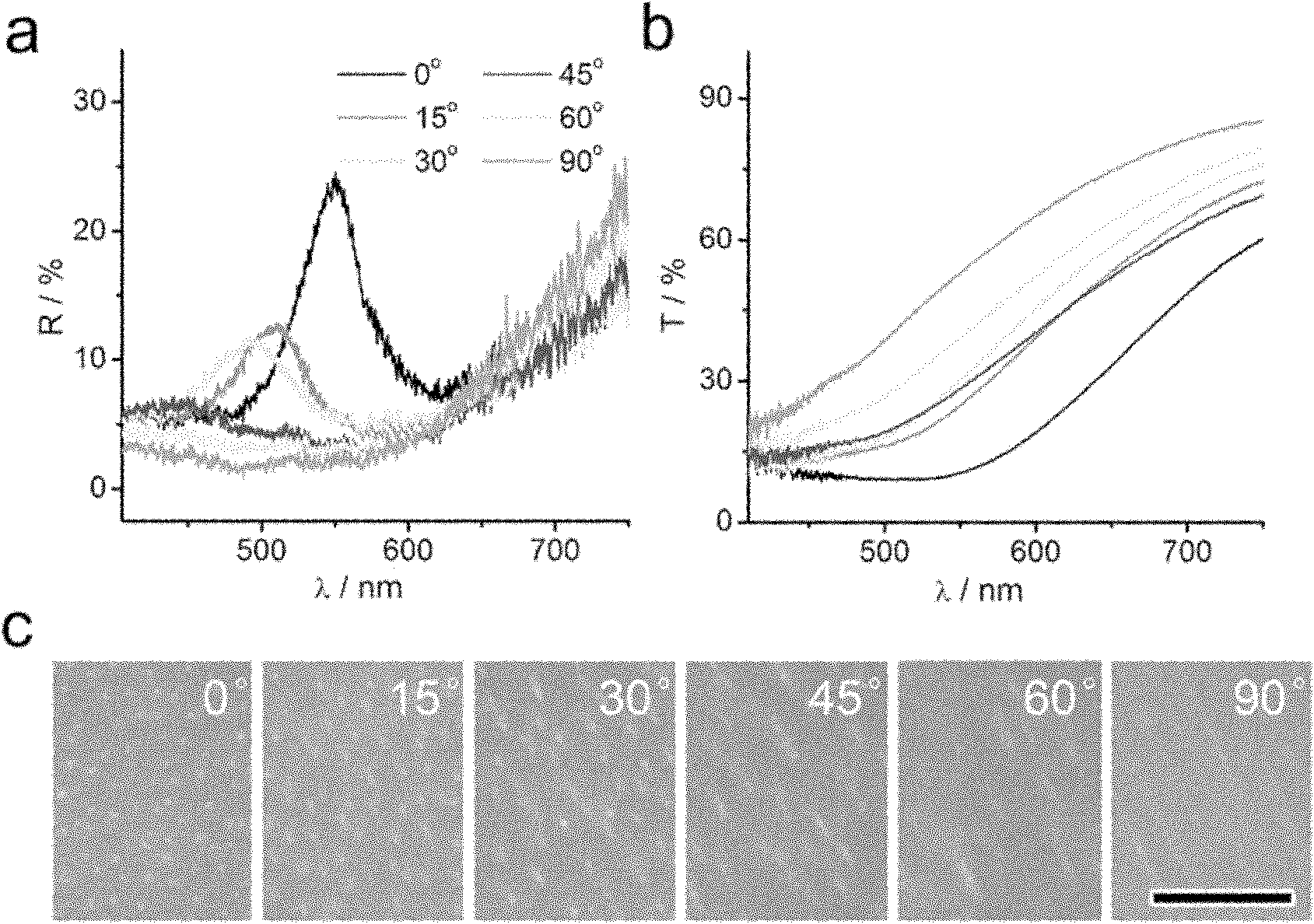

[0032] Printing Mirror Symmetrically Oriented Photonic Crystal Labels

[0033] Take an appropriate amount of photonic crystal printing solution and place it between the glass substrate and the hydrophobic cover glass with a distance of 280 μm, and place it above the inclined NdFeB magnet, adjust the magnetic field direction to 15°, under the action of the external magnetic field, the magnetic colloidal particles A chain-like one-dimensional photonic crystal structure is formed, and the crystal orientation is consistent with the direction of the external magnetic field. At the same time, the photonic crystal structure and orientation of the selected area were fixed by irradiation under ultraviolet light for 15 seconds using a photomask. Adjust the direction of the external magnetic field to -15° of mirror symmetry, remove the photomask, and cure other areas under UV irradiation to form patterns with "orientation differences". When the angle of the incident light is switched betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com